Thickness: 0.15 - 2.0 mm

Technique: Hot Rolled

Application: Container Plate

Surface Treatment: Galvanized

Secondary Or Not: Non-secondary

Certification: CE

Special Pipe: Thick Wall Pipe

Alloy Or Not: Non-alloy

Section Shape: Other

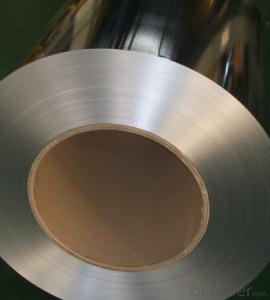

Galvanized Steel Coil Hot Dipped for construction CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1.Quick Details:

2.Packaging & Delivery

| Packaging Details: | standard package |

|---|---|

| Delivery Detail: | 1-4 week |

cold rolled galvanizing steel coil

galvanized iron steel coil

| Product name | hot rolling galvanized steel coil |

| Raw material | SGCC, SPCC, DC51D, SGHC,A653 |

| Certificate | ISO9001,BV,SGS |

| Thickness | 0.13mm-2.0mm |

| Width | 1250mm or under |

| Tolerance | thickness+/-0.01mm |

| Surface treatment | galvanized steel sheets |

T Bending (top-coating) T Bending (back-coating) | ≤3T ≤4T |

| Anti-MEK Wiping | ≥100times |

| Zinc coating | 40-180g |

| Type of coating structure | 2/1 or 2/2 coating, or customized |

| Standard | GB/T12754-2006, GB/T9761-1988, GB/T9754-1988, GB/T6739-1996, HG/T3830-2006, HG/T3830-2006, GB/T1732-93, GB/T9286-1998, GB/T1771-1991, GB/T14522-93 |

| Color | Silver |

| Application | construction material for building industry ,structural use, roofing, commercial use ,household appliance,industry facilities,office buildings |

5.What is the application of Steel Coil?

There are two sides,one is out side: Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth;the other is inside: Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter.

- Q: Which steels were origianally designed to be used to cut and shape metals and other materials?- alloy steel- high carbon steel- carbide steel- tool steelthanks

- Tool steels These were designed to be used as hardenable, dimensionally stable materials for cutting of metals. The alloying elements they contain (including tungsten, vanadium, niobium and molybdenum as well as chromium)are there to produce carbides (mainly) which are stable at dull-red heat. This cannot be achieved with high carbon steels, carbide steels or (normal) alloy steels which all lose their strength and hardness at metal cutting temperatures.

- Q: i'm looking into pedal steel guitars, and I would like some suggestions or links and info on what kind i should get.

- Try okorder -The Art of Steel Guitar/ Steel guitar players -Take it away Leon- McAuliffe and 'Speedy West' were a couple greats. In the late '50s, Speedy was playing a Fender 1000 Pedal steel. He often did duets with Jimmy Bryant The Fastest Guitar Player In The Country! / note also the 'Emmons Guitar Company':

- Q: What are the different types of steel coil surface appearances?

- The different types of steel coil surface appearances include hot rolled, cold rolled, galvanized, coated, and textured finishes.

- Q: How are steel coils processed and treated?

- Steel coils are processed and treated through a series of steps. Initially, the steel is cleaned and pickled to remove any impurities. It is then passed through a series of rolling mills to reduce its thickness and increase its length. The coils are then annealed to improve their strength and ductility. Further treatments such as galvanizing or coating can be applied to enhance corrosion resistance or improve aesthetic appeal. Finally, the coils are cut and packaged according to customer specifications before being shipped for various applications in industries such as construction, automotive, and manufacturing.

- Q: How are steel coils used in the production of steel bolts?

- Steel coils are used in the production of steel bolts as they serve as the primary raw material. The coils are unwound and fed into a machine that cuts and shapes the steel into bolts of the desired size and shape. The coils provide a continuous supply of high-quality steel, ensuring the consistency and strength of the bolts produced.

- Q: Can steel coils be coated with epoxy?

- Yes, steel coils can be coated with epoxy. Epoxy coatings provide protection against corrosion and enhance the durability and lifespan of the steel coils.

- Q: This question gets beat to death from what ive seen online but im going to ask it since im searching for a few new knives. The question is as the titles states what is the best steel for a general purpose knife? I plan on buying several different types of knives, Folders, fixed blades, ect. I will carry them around with me all the time for basically anything i can think of to use it for. The reason i ask this question here is because looking online everyone has a differnt veiw. Some say stainless is too soft while others say carbon will chip and is more brittle. Even looking at just a single type of steel, carbon fort instance everyone has a different opinion as to whats best leaving me kind of lost for what i should get. Maybe the better word would be What is a good general purpose steel?. Any advice is much appreciated!!!!

- Fixed Blades: Folding Blades: CPM 3V CPM S35-VN 1095 CPM S30-V 5160 AUS-8 (when it's heat treated right)

- Q: How are steel coils used in the production of industrial valves?

- Steel coils are used in the production of industrial valves as they provide a high-strength and durable material for constructing the valve bodies, stems, and other components. The coils are typically shaped, cut, and formed into various valve parts, which are then assembled and welded together to create the final valve product.

- Q: I need help my new stainless steel cookware is sticking ? My first meal was nasty!

- Food sticks to stainless steel. Gourmet cooks love it for that very reason. Without sticking, foods won't sear properly. For the rest of those cooks out there, nonstick is often an easier option. If you want to make a go of the stainless, here are some tricks of the trade.... a)always preheat the pan on low-medium b)never put cold food into a hot pan. It will stick worse.Leave cold food on counter for 15 minutes before it hits the pan. c)after preheating the pan, add oil, or an oil/butter combo d)for foods like eggs, potatos, grilled cheese, nonstick is your best friend. e) when you take food out of pan, immediately wipe the pan out with a kitchen towel. Keeps cleanup from being a nightmare. f) don't wash pans in sink while hot. They will warp. Stainless takes some getting used to. Hope this helps!

- Q: I love the design! It looks great, is safe, and you can see through it just fine on camera. Do you like it?BQ: Old Blue WWF Steel Cage or the newer fence type steel cage?

- yes it is better now

Send your message to us

Galvanized Steel Coil Hot Dipped for construction CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords