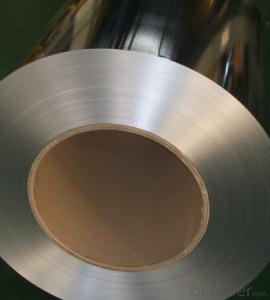

Hot Dipped Galvanized Steel Coils for construction CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Quick Details:

hot dipped galvanized steel coil

Material: | SGCC, DX51D+Z |

Thickness: | 0.13-0.8mm |

Width: | 750-1250mm |

Zinc coated: | 40-180g/m2 |

Standard: | ASTM,AISI,DIN,GB |

Spangle: | Zero Spangle, Regular Spangle, Small Spangle |

Surface treatment: | chromated and oiled, chromated and non-oiled |

Technique: | cold rolled galvanized |

Grade: | Prime |

ID: | 508mm or 610mm |

Coild weight: | 3-5MT/Coil or as your request |

Quality: | Softy , half hard and hard quality |

2.Packaging & Delivery

Packaging Details:Fully seaworthy export packing. Each coil is wrapped in water-proof paper.Fixed with steel strips.

Delivery Detail:about 12 days

3.Festure:

Certificate: | ISO9001, BV test |

MOQ: | 20MT |

Supply Ability: | 3000MT/month |

OEM: | Accept |

Price Item: | FOB, CFR, CIF |

4.Specification:

Standard | EN 10327 | DX51D+AZ, DX52D+AZ, DX53D+AZ, |

EN 10326 | SS250GD+AZ, SS350GD+AZ | |

JIS G3321 | SGLCC, SGLCD, SGLCDD, SGLC 400 | |

ASTM A792M | CS type C, CS type B, DS, SS255, SS345 | |

Base Metal | Cold rolled steel coils SPCC, SPCD, SPCE, DC01, DC03, DC04, CS, DS, DDS, Q195, Q250, Q350 | |

Thickness | 0.22mm-2.0mm | |

Width | 700mm-1300mm | |

Coil ID | 508mm, 610mm | |

Zinc coating | 60g/m2-180g/m2 | |

Surface treating | chromium free passivation, chromium passivation, fingerprint resistant, oiled | |

Spangle types | regular spangle | |

5.What is the application of Steel Coil?

There are two sides,one is out side: Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth;the other is inside: Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter.

- Q: What is the maximum width of galvanized steel strip, please? The galvanized coat is 275, and how long is one coil?

- As far as I know, the galvanized rolls of WISCO are wider in width than other domestic steel mills, and can produce 2080 wide steel coils.

- Q: Why is iron used to create steel? Why not other elements?

- iron came before steel. iron is what was discovered that, under certain circumstances, became a stronger metal: steel. that is why. its like asking why copper is in bronze. because what we call bronze, is an alloy of copper and tin. if you give a more detailed question, i may be able to give a more detailed answer.

- Q: Where can I find a discount online for Stainless Steel Magnetic Knife Rack

- Hi okorder /

- Q: If you combine stainless steel with gold, does that make stainless gold?

- Nope, Stainless Steel is a tradename for a certain alloy. Regular Steel, which is formed from Ferrous Oxide (via the Bessimer Process). The stainless part is because they mixed in some other compound to give it unique qualities. Gold, on the other hand, is a pure element, and it can form alloys with other metals, but there are no guarantees what the properties will be

- Q: Has anyone painted their appliences with stainless steel paint? I found on the internet what is called Thomas Liquid stainless steel paint. If you have used it for your kitchen appliences or cabinets, how were the results? How hard was it to apply? Would you recommend it?

- If okorder /

- Q: How can the quality of steel coils be ensured?

- The quality of steel coils can be ensured through a combination of careful selection of raw materials, closely monitored manufacturing processes, and rigorous quality control measures. This includes conducting regular inspections and tests at various stages of production to ensure that the steel coils meet the required specifications and standards. Additionally, implementing proper storage and handling procedures, as well as adhering to industry best practices, can help maintain the quality of steel coils throughout their lifecycle.

- Q: How are steel coils used in the production of prefabricated buildings?

- Steel coils are used in the production of prefabricated buildings as they are flattened and cut into specific sizes to serve as the structural framework. These coils are typically formed into beams, columns, and other essential components, which are then assembled and interconnected to create the building's frame. The strength and durability of steel make it an ideal material for prefabricated structures, ensuring the safety and stability of the buildings.

- Q: How are steel coils used in the production of steel pipes?

- Steel coils are an essential component in the production of steel pipes. These coils serve as the raw material that is used to manufacture the pipes. The first step in the process involves unwinding the steel coil and feeding it into a machine called a slitter. The slitter cuts the coil into narrower strips of the desired width. This width is crucial as it determines the diameter of the steel pipes that will be produced. Once the steel coil has been slit into strips, the next step is to feed these strips into another machine called a forming mill. The forming mill gradually shapes the strips into a cylindrical shape by passing them through a series of rollers. These rollers apply pressure and bend the strips until they take on the form of a pipe. To ensure the durability and strength of the pipes, they undergo a welding process. The ends of the strip are heated and fused together using a high-frequency electric current, resulting in a continuous weld along the length of the pipe. This weld provides structural integrity and prevents any leakage or weak spots in the pipe. After the welding process, the pipes go through a sizing and shaping process. They are passed through additional rollers and gradually reshaped to achieve the desired dimensions, including the final outer diameter and wall thickness. Finally, the pipes are cut to the desired length and undergo various finishing processes such as straightening, testing, and coating. These finishing steps ensure that the pipes meet the required specifications and are ready for use in various applications, such as plumbing, construction, and oil and gas industries. In summary, steel coils are the starting point for the production of steel pipes. They are slit, formed, welded, sized, shaped, and finished to create durable and high-quality pipes that can be used in a wide range of industries.

- Q: How much should someone sell a 6 ft stainless steel counter? How about one with a sink?

- Ask for the best offer on OKorder and find out.

- Q: What are the typical lead times for steel coil orders?

- The typical lead times for steel coil orders can vary depending on factors such as the quantity, specifications, and availability. However, on average, lead times can range from a few weeks to several months. It is recommended to check with the specific supplier or manufacturer for accurate lead time estimates.

Send your message to us

Hot Dipped Galvanized Steel Coils for construction CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords