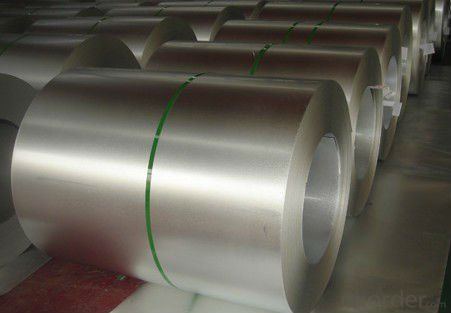

Hot dipped galvanized steel coils CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 300000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | China (Mainland) | Brand Name: | CNBM | Model Number: | 0.13-0.6mm*750-1250mm |

| Material: | SGCH SGCC SPCC DX51D | application: | construction,automobile,household appliance,etc. | surface: | galvanized,chromated,dry,skin pass... |

| skin pass: | chromated | technique: | cold rolled | spangle: | zero/big/regular/minimum |

| tempering: | bright annealed or full hard | grade: | prime | zinc coating: | 50-220gsm |

| coil weight: | 3-5mt | coil id: | 508mm/610mm |

Packaging & Delivery

| Packaging Detail: | mill's standard packing,sea worthy packing,steel pallets |

| Delivery Detail: | within 15-30 days after received the deposit or the LC at sight |

Specifications

hot dipped galvanized steel coils

1.FOB:650-1000SUSD/TON

2.size:0.13-0.6mm*750-1250mm*C

3.zinc coating:50-220gsm

4.chromate

hot dipped galvanized steel coils

NAME

| PPGI |

GALVANIZED

|

GALVALUME/ALUZINC

|

CERTIFICATE | ISO9001:2008 | ||

GRADE

| CGCC CGCH CGCD1-CGCD3 CGC340-CGC570 GRADE

| SS GRADE33-80 SGCC SGCH SGCD1-SGCD3 SGC340-SGC570 SGCC DX51D | GRADE33-80 SGLCC SGLCD SGLCDD SGLC400-SGLC570 SZACC SZACH SZAC340R |

MODEL NO | 0.16MM-0.8MM*1250MM OR UNDER | (0.127-1.2*1250MM OR UNDER | 0.12MM-2MM*1250MM OR UNDER |

TYPE

|

Steel coil Steel sheets/plates Corrugated steel sheets/plates

| Steel coil Steel sheets/plates Corrugated steel sheets/plates |

Steel coil Steel sheets/plates Corrugated steel sheets/plates

|

TECHNIQUE |

Ccold rolled -galvalume /galvanized -PPGI/PPGL | Cold rolled - galvanized |

Cold rolled -galvalume /Aluzinc

|

SURFACE TREATMENT | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating,color

| Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating

| |

APPLICATION | Structural use ,roofing, commercial use, household appliance, industry, family

| ||

SPECIAL APPLICATION | Wear resistant steel, high- strength - steel plate | ||

company

production line

package

- Q: Ok I have a neodymium magnet, stuck to my fridge holding a old bottle cap opener for my beer it works fine. At the local rummage sale there was a beautiful cap opener my freind was selling for $0.25 she said had never beenUsed it was like 40 years old it is made a stainless steel. The magnet will not stick to it. I don't understand this looked this up and certain steels are not magnetic, I tried a experiment with my compass it don't point north as should it follows the bottle opener as I move it around it. If not magnetic why is this happening? Also tried placing near another neodymium magnet with a pull of about 200 lbs. Not I tiny bit of attraction to the metal. If so why is the tiny magnet in the compass attracted to it. But not a huge powerfull magnet.

- That's interesting that it caused deflection in the compass. A lot of stainless steels may be SLIGHTLY magnetic, because they have small amounts of ferrite or alpha-iron in them. Ferrite is one of the crystal phases of steel. It has a body-centered cubic (BCC) structure and it's responsible for the magnetism of ordinary steels. Adding certain elements like nickel, manganese, or molybdenum, changes the crystal structure of the steel to a face-centered cubic (FCC) structure, which is NOT magnetic. This crystal phase is known as Austenite or gamma-iron. However most iron alloys contain some impurities that may cause the steel to be not completely transformed into the FCC austenite phase, small areas remain as ferrite.

- Q: What are the different types of steel coil finishing machines?

- There exists a variety of steel coil finishing machines, each designed to accomplish specific tasks and attain desired outcomes. Some commonly encountered types are as follows: 1. Slitting Machines: These machines are employed to divide large steel coils into narrower strips of desired widths. They comprise a set of circular blades that cut through the coil as it progresses through the machine, resulting in multiple smaller coils or strips. 2. Cut-to-Length Machines: These machines are utilized to cut steel coils into specific lengths. They can be programmed to execute precise cuts at predetermined lengths, thereby ensuring accuracy and consistency. 3. Recoiling Machines: Recoiling machines are deployed to rewind steel coils into tightly wound, compact rolls. They are typically used to create smaller coils from larger ones or to recondition coils that have become loose or damaged. 4. Edging Machines: Edging machines serve the purpose of removing excess material from the edges of steel coils, thereby enhancing their overall appearance and ensuring uniform width throughout the coil. 5. Coating Machines: These machines are utilized to apply diverse coatings or finishes to the surface of steel coils, such as paint, galvanized coatings, or protective films. They often incorporate drying or curing systems to guarantee proper adhesion and durability of the applied coatings. 6. Packaging Machines: Packaging machines are employed to wrap or package steel coils for transportation or storage. They can envelop the coils in protective materials, such as plastic or paper, and secure them using strapping or other fastening methods. 7. Inspection Machines: These machines are used to scrutinize the quality and integrity of steel coils. They have the capability to detect defects, such as cracks, scratches, or surface irregularities, and provide feedback for the purpose of quality control. These examples merely scratch the surface of the diverse array of steel coil finishing machines available. Each machine serves a specific role in the steel coil finishing process, guaranteeing that the final product meets the desired specifications and quality standards.

- Q: I went to the store to get metal to make a knife and they had weldable steel and plate steel. Which one would be best/ which steels would be best for what i want to do?

- 'Plate' does not refer to a specific alloy. It simply describes the shape in which the metal is sold. Various steel alloys have varying degrees of weldability. Some weld well, with good strength. Others weld poorly, and crack or become very weak. Try looking up information on the specific alloy of steel.

- Q: can anyone tell me the way to bring back the shine to the stainless steel kitchen sink . It has become dull.

- these stainless steel are easy clean and polish so you can purchase online these website given as below: www.gecanderson .uk/product/made-to-measure/shelving/

- Q: How do steel coils contribute to energy efficiency in transportation?

- Steel coils contribute to energy efficiency in transportation in several ways. Firstly, steel coils are lightweight and have a high strength-to-weight ratio. This means that less steel material is required to carry the same load compared to other materials, such as wood or concrete. As a result, the overall weight of the transport vehicle is reduced, which leads to lower fuel consumption and emissions. Secondly, steel coils are highly durable and can withstand harsh conditions during transportation. They have excellent resistance to corrosion, impact, and fatigue, ensuring a longer lifespan for the transport vehicle. This durability reduces the need for frequent repairs or replacements, resulting in reduced energy consumption and material waste. Furthermore, steel coils are easy to handle and transport. They can be easily loaded and unloaded from trucks, trains, or ships due to their compact and standardized size. This efficiency in handling reduces the time and energy required for loading and unloading operations, thereby increasing overall transportation efficiency. Additionally, steel coils can be efficiently stacked and stored, maximizing the use of available space in transport vehicles. This reduces the number of trips required to transport the same amount of goods, resulting in less energy consumption and lower transportation costs. Lastly, steel is a highly recyclable material. At the end of their life cycle, steel coils can be easily recycled and used to produce new steel products. This reduces the demand for raw materials and the energy required for manufacturing new products, contributing to overall energy efficiency in transportation. In conclusion, steel coils contribute to energy efficiency in transportation through their lightweight, durable, easy-to-handle, and recyclable nature. These characteristics result in reduced fuel consumption, lower emissions, decreased maintenance needs, efficient use of space, and reduced material waste, all leading to a more sustainable and energy-efficient transportation system.

- Q: Which one would be stronger? And should damascus steel be tempered?Thank You

- carbon steel it is stronger it is the type ill be using when i stare forging

- Q: Ok, so im gonna get my tragus pierced and i was wondering which is better, titanium or stainless steel. I hear like everyone uses stainless steel , but is titanium better?Thanks

- It seems like less people are allergic to titanium than surgical grade steel.

- Q: What is the average flatness tolerance for steel coils?

- The average flatness tolerance for steel coils varies depending on the specific industry and application. However, in general, most steel coil manufacturers aim for a flatness tolerance of around 0.25% to 0.5% of the material's thickness.

- Q: steel of beam has been rusted ,how can i repair it?

- chrome steel is an alloy of iron and different metals, fairly Chromium and vanadium. you do no longer see it with the bare eye yet on the exterior of any chrome steel (SS) there are iron atoms and chromium atoms that are uncovered. in spite of the shown fact that, the chromium reacts preferentially to type an oxide. In essence, think of of chromium sacrificing itself for iron so as that iron won't rust. What a helpful guy huh! it somewhat is reported as passivation purely like maximum responders suggested. in spite of the shown fact that, greater desirable than that the chromium oxide varieties a good shielding layer that varieties a actual barrier combating Oxygen or any oxidant to realize and attack the iron below it. additionally, the chromium oxide shaped isn't FLAKY and porous, so it does not mar maximum of the exterior as an iron oxide (rust) would. For technology project, you won't make it too technical yet you additionally could make a reference or make an ANALOGY of rust prevention to intense college or social circumstances as being there to your pal or classmate yet in real existence, whilst the possibilities are too great, that secure practices afforded via chromium won't be adequate. because of the fact ultimately all steel uncovered to very oxidizing atmospheres will rust. in basic terms somewhat ruin in the exterior is sufficient to initiate the technique of rusting.

- Q: How are steel coils used in the manufacturing of automotive suspension systems?

- Steel coils are used in the manufacturing of automotive suspension systems as they provide the necessary support and flexibility to absorb shocks and vibrations. These coils are typically placed between the vehicle's frame and the axle, allowing the suspension to compress and rebound when encountering bumps or uneven terrain. By absorbing and distributing the impact forces, steel coils ensure a smoother and more comfortable ride for the passengers while also enhancing the vehicle's stability and handling capabilities.

Send your message to us

Hot dipped galvanized steel coils CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 300000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords