G8 Aluminum Coil - PE Color Coated Aluminium Coils for Decoration AA3003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

PE Coated aluminium coils are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. However, the price of PE Colored aluminium coils is much more competitive than PVDF aluminium coils. So many customers prefer PE coated aluminium coils.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

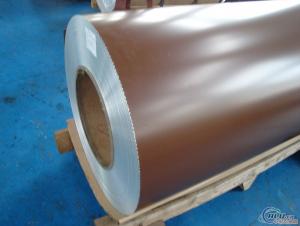

3.Image

4. Products Specification

| Alloy | Painting | Color Series | Coating Thickness | Coil Weight |

| AA3003 | PE | RAL | 22-25 MICRONS | About 2.5 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 8 tons.

- Q: How are aluminum coils used in the production of automotive radiators?

- Aluminum coils are used in the production of automotive radiators as they provide excellent heat transfer properties. These coils are typically made from aluminum alloy, which is lightweight, corrosion-resistant, and has high thermal conductivity. The coils are formed into a specific shape and then attached to the radiator's core. As coolant flows through the coils, heat from the engine is transferred to the aluminum, which efficiently dissipates it. This helps in cooling the engine and maintaining its optimal operating temperature. Overall, aluminum coils play a crucial role in enhancing the efficiency and performance of automotive radiators.

- Q: How do aluminum coils contribute to recyclability in the construction industry?

- Aluminum coils play a crucial role in enhancing recyclability in the construction industry due to their inherent properties and characteristics. Firstly, aluminum is a highly recyclable material, meaning it can be recycled repeatedly without losing its quality or physical properties. This makes aluminum coils a sustainable and eco-friendly choice for construction projects. The recyclability of aluminum coils helps reduce the environmental impact associated with the construction industry. By choosing aluminum coils, construction companies can contribute to the conservation of natural resources and the reduction of energy consumption. Recycling aluminum requires significantly less energy than producing it from raw materials, resulting in a substantial reduction in greenhouse gas emissions and carbon footprint. Moreover, the use of aluminum coils in construction facilitates the dismantling and deconstruction processes, making it easier to separate the aluminum components from other materials. This efficient separation allows for the effective recycling of aluminum coils, ensuring that they can be transformed into new products or materials. Additionally, aluminum's durability and resistance to corrosion make it a suitable choice for construction applications. Its long lifespan reduces the need for frequent replacements, further minimizing waste generation and the consumption of raw materials. When the time comes to replace or renovate a building, the aluminum coils can be easily collected, recycled, and reintroduced into the manufacturing cycle, closing the loop of the material's lifecycle. In summary, aluminum coils significantly contribute to recyclability in the construction industry. Their high recyclability, low energy requirements for recycling, and ease of separation during deconstruction make them an environmentally friendly choice. By utilizing aluminum coils, the construction industry can promote sustainability, reduce waste generation, and conserve natural resources, ultimately leading to a greener and more circular construction sector.

- Q: How are aluminum coils coated or finished?

- Aluminum coils can be coated or finished in various ways to enhance their appearance, protect against corrosion, or improve their functionality. The most common methods of coating or finishing aluminum coils include painting, anodizing, and laminating. Painting is a popular coating method where a layer of paint is applied onto the aluminum surface. This can be done through different techniques such as spray painting, roll coating, or coil coating. The paint can be customized in terms of color, gloss level, and texture, allowing for a wide range of aesthetic options. Additionally, painting can provide protection against atmospheric conditions and increase the durability of the coils. Anodizing is another widely used technique, especially for architectural and industrial applications. It involves creating a controlled oxide layer on the surface of the aluminum through an electrochemical process. Anodized aluminum coils have a uniform and durable finish that enhances their resistance to corrosion, scratching, and fading. They are available in various colors and can be further enhanced with a matte, brushed, or polished appearance. Laminating is a process where a thin layer of protective film is applied onto the surface of the aluminum coil. This film can be made of different materials such as PVC, polyester, or polyethylene. Laminating provides an extra layer of protection against scratches, dirt, and UV radiation. It also allows for easy cleaning and maintenance of the coated aluminum coils. In addition to these methods, aluminum coils can also be coated with specialized finishes for specific applications. For example, coils used in the automotive industry may have a polymer-based coating that provides lubricity and reduces friction. Coils used in the construction industry may have a heat-reflective coating to improve energy efficiency. Overall, the coating or finishing of aluminum coils plays a crucial role in enhancing their appearance, protecting against corrosion, and improving their functionality for various applications. The choice of coating method depends on the desired outcome, budget, and specific requirements of the end-use industry.

- Q: What are the different packaging weights available for aluminum coils?

- The different packaging weights available for aluminum coils vary depending on the specific requirements and applications. Common packaging weights for aluminum coils range from 1,000 to 10,000 pounds or more. These weights can be customized to meet the needs of different industries and transportation methods.

- Q: How do aluminum coils contribute to sustainable energy systems?

- Aluminum coils contribute to sustainable energy systems by being lightweight, durable, and highly conductive, making them ideal for various renewable energy applications. They are commonly used in solar panels, wind turbines, and electric vehicles, as the coils help enhance energy efficiency and reduce carbon emissions. Additionally, aluminum is easily recyclable, promoting a circular economy and reducing the environmental impact of energy systems.

- Q: I was told today that taking aluminium inside your body greatly increases the chance of getting alzheimers as they destroy cells. What foods contain aluminium?

- i dont think any foods will contain substantial quantities of aluminium as its not a metal commonly found in bioinorganic chemistry. Aluminium salts could potentially be found in water, also using aluminium pans could potentially lead to aluminium consumption. hope this helps

- Q: What is the balanced chemical equation for aluminum and cobalt?That is all the information that the question gives. If you could help me out, I would really, really appreciate it.

- That's pretty sparse. Perhaps the question is referring to a single replacement reaction. Aluminum is above cobalt in the activity series, which allows us to predict that aluminum metal will reduce cobalt ions, while aluminum is oxidized. This occurs as long as there is an ion present which will react with the aluminum oxide layer on the surface of aluminum. This passivating Al2O3 layer keeps aluminum metal from reacting. The presence of chloride ions will break down the passivating layer allowing the aluminum metal below to react. Al2O3(s) + 6H+ + 8Cl- -- 2[AlCl4]- + 3H2O(l) 2Al(s) + 3Co2+ -- 2Al3+ + 3Co(s)

- Q: I am looking for a deoderant that doesn't contain aluminum that actually works. I have tried Tom's natural deoderant and didn't get to use it long enough to see if it worked because it really irritated my skin and caused it to burn and peel. I have also tried the one made by Adidas and it seemed to work pretty well through the winter months, but now that it is getting warm again I'm noticing that it isn't quite doing the job anymore.

- aluminum zirconium is the chemical that makes you stop sweating, not that it works on most people. they can only put a certain percentage of it in deodorants, try the degree clinical, i just started using it and it seems to be doing okay, good luck i know what you are going through.

- Q: I have aluminum windows that have to be replaced due to bad thermopanes - there is accumulated grime and humidity in between the panes. Is it possible to buy individual custom-sized replacements or do I have to get all new windows and frames? Any referrals would be helpful.

- this is one of the hardest replacement jobs as far as windows. You have to cut out the whole window as the replacement windows frames are thicker than the aluminum windows. Two you will have exterior and interior work to do to finish them out. I would shop around to see what kind of pricing is in your area. Also look at tax credit qualifying windows must have a U value of .30 or lower to qualify. You can get 30% back up to 1500.00. I know window world will qualify but not there standard window. you must get glass option upgrade. Plus they will charge 50.00 extra labor to remove the metal window 60.00 to cap the exterior 45.00 for interior trim. and 279.00 for tax credit qualifing window. Total 435.00 per window. There are other companies out there just not sure what they charge but should be close to this.

- Q: Can aluminum coils be used in the production of aluminum downspouts?

- Yes, aluminum coils can be used in the production of aluminum downspouts. Aluminum coils are commonly used in the manufacturing process of downspouts as they can be easily formed and shaped into the desired downspout design. The flexibility and durability of aluminum make it an ideal choice for downspout production, ensuring longevity and resistance to corrosion.

Send your message to us

G8 Aluminum Coil - PE Color Coated Aluminium Coils for Decoration AA3003

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords