PVDF PE Coated Color Aluminum Coil for Gutter Machine ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Specifications

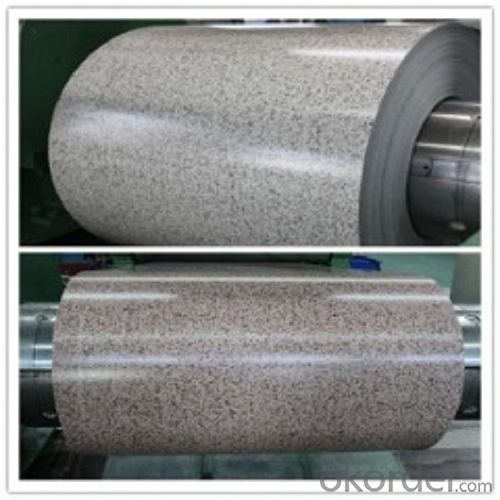

Painted Aluminium Coil

1) Temper: H14, H18, H24 mainly.

2) Alloy 1100, 1050, 3003,3004, 5052, 8011 etc

3) Origin: China

Painted Aluminium Coil:

1) The type of paint: PE, PVDF, PA, PU

2) Thickness coating: PVDF: More then 25 micron; PE, more then 18 micron.

3) Paint supplier: PPG (PVDF)

4) Interior diameter: Mainly in 405mm, 505, mm

5) Width: Less then 1600mm, sheets are also available

6) Color: Panton, RAL or refer to customers' counter sample.

7) Coating hardness: (pencil hardness) more than 2H

8) Impact resistance: No cracking and peeling (50kg/cm, ASTMD-2794: 1993)

9) Flexibility (T-bend): No more than 2T

10) MEK resistance: More than 100

The base of Painted Aluminium Coil details:

1) Temper: H14, H18, H24 mainly.

2) Alloy 1100, 1050, 3003, 3004, 3005, 5052, 8011 etc

3) Origin: China

4) MOQ: 5 tons each size

5) Lead Time: Within 20 days

6) The term of payment: T/T, irrevocable L/C at sight

7) Application: Curtain wall, roof, internal and external wall, ACP, Door

l Packaging & Delivery:

Packaging Details: 1.with wooden pallet packing.

2.standard fumigated wooden package.

3.other packing methods by customer's requirement.

Delivery Details: 30-40days

l Company Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 10 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Email: service@okorder.com

- Q: How are aluminum coils used in the automotive industry?

- Due to their numerous advantages over traditional materials, aluminum coils play a crucial role in the automotive industry. They are widely used in various parts and components of vehicles, enhancing performance, improving fuel efficiency, and reducing overall weight. A primary application of aluminum coils in the automotive industry is in the manufacturing of heat exchangers, such as radiators and condensers. Aluminum's excellent thermal conductivity enables efficient heat transfer, regulating engine temperature and optimizing performance. By incorporating aluminum coils in heat exchangers, vehicles can achieve better cooling efficiency, preventing engine overheating and maintaining optimal operating conditions. Furthermore, aluminum coils are utilized in the production of air conditioning systems, specifically in the condenser and evaporator units. These coils have excellent heat exchange capabilities, enabling efficient cooling or heating of the vehicle's interior. As a result, vehicles equipped with aluminum coil-based air conditioning systems can provide a comfortable environment for passengers while minimizing energy consumption. Moreover, aluminum coils are used in constructing lightweight body panels and structural components like doors, hoods, roofs, and chassis. Aluminum's high strength-to-weight ratio makes it ideal for reducing vehicle weight without compromising structural integrity. This weight reduction leads to improved fuel efficiency, reduced emissions, and enhanced performance in acceleration, handling, and braking. Additionally, aluminum coils find application in producing electrical systems in automobiles. Their excellent electrical conductivity makes them suitable for wiring harnesses, connectors, and other electrical components. The use of aluminum coils in these systems ensures efficient transmission of electrical signals and reduces overall vehicle weight, contributing to improved fuel economy. In conclusion, aluminum coils are extensively used in the automotive industry for various purposes, including heat exchangers, air conditioning systems, body panels, and electrical components. The exceptional properties of aluminum, such as thermal conductivity, strength-to-weight ratio, and electrical conductivity, enable automakers to produce lighter, more efficient, and environmentally friendly vehicles.

- Q: Can aluminum coils be used in the production of household appliances?

- Yes, aluminum coils can be used in the production of household appliances. Aluminum is a lightweight and durable material that has excellent thermal conductivity, making it ideal for applications in appliances such as refrigerators, air conditioners, and heat pumps. Aluminum coils are commonly used in the condenser and evaporator coils of these appliances, where they help transfer heat efficiently. Additionally, aluminum coils are resistant to corrosion, which is important for ensuring the longevity and performance of household appliances. Overall, aluminum coils are a popular choice in the production of household appliances due to their properties and benefits.

- Q: Can aluminum coils be used in chemical processing plants?

- Yes, aluminum coils can be used in chemical processing plants. Aluminum is resistant to many chemicals, especially in non-acidic environments. It is lightweight, has good thermal conductivity, and can withstand high temperatures, making it suitable for various applications in chemical processing plants.

- Q: Aluminum reacts with water so why is it used in buildings and cooking??Some help by today would be good!! :DThanxx

- Aluminum reacts with water under certain conditions, but cookware does not usually present any of those conditions. Aluminum cookware takes advantage of the oxidizing process, which creates a natural protective layer over the aluminum. It doesn't react with water in the same way that chemical equations say it will because cooking surfaces are designed to maximize the oxidation effect. This is basically the same reason why aluminum foil doesn't react in water. In building materials, it's less about exposure to the elements and more about how cheap and lightweight it is. Many building materials are aluminum alloys, which makes them more susceptible to corrosion than purer aluminum, and the use of aluminium roofing material, though fairly corrosion-resistant by itself (for the same reasons as cookware), gets compromised by the proximity of other metals used in construction, like non-stainless steel nails and screws, for example, or copper pipes without insulation. The trade-off is that aluminium alloys hold their shape better and have greater tensile strength, some of which approach that of steel.

- Q: a) Although Aluminium is a reactive metal, it is used to make door frames and window frames.b) Although Aluminium conducts heat, it is used to make blankets, which are good thermal insulators.

- a] AL is used to make frames because it is light, not costly and strong.

- Q: What are the potential applications of coil-coated aluminum coils?

- Coil-coated aluminum coils possess exceptional properties and versatility, thus presenting a wide range of potential applications. Some notable uses of coil-coated aluminum coils include: 1. Construction and Architecture: The construction industry extensively employs coil-coated aluminum coils for roofing, wall cladding, facades, and decorative elements. These coils can be easily shaped and customized to meet specific design requirements, while their coil coating ensures durability, weather resistance, and color retention. 2. Transportation: Coil-coated aluminum coils find widespread usage in the transportation industry, particularly in the manufacturing of automobiles, buses, trains, and aircraft. The lightweight nature of aluminum makes it an ideal choice for enhancing fuel efficiency and energy conservation. Moreover, the coil coating enhances corrosion resistance, aesthetics, and overall durability of the aluminum coils. 3. Appliances and Electronics: Manufacturing appliances and electronics, including refrigerators, air conditioners, ovens, and televisions, commonly involves the use of coil-coated aluminum coils. The coil coating provides a protective layer that prevents corrosion and extends the lifespan of these products. Additionally, the aesthetic appeal and variety of colors offered by coil-coated aluminum coils contribute to the overall design and aesthetics of appliances and electronics. 4. Signage and Displays: The versatility and visual appeal of coil-coated aluminum coils make them a popular choice for signage and displays. The coil coating enhances the durability, weather resistance, and color vibrancy of the aluminum, making it suitable for both indoor and outdoor applications. Whether it be large billboards, shop signs, or exhibition displays, coil-coated aluminum coils offer a cost-effective and visually appealing solution. 5. Packaging: Coil-coated aluminum coils are extensively used in the packaging industry for various purposes, such as cans, containers, and lids. The coil coating provides a protective layer that prevents the aluminum from reacting with the contents, ensuring product integrity and safety. Additionally, the lightweight nature of aluminum makes it an environmentally friendly option for reducing packaging waste. 6. Energy and Solar: The energy and solar industry is increasingly incorporating coil-coated aluminum coils. The lightweight and corrosion-resistant nature of aluminum make it an ideal material for manufacturing solar panels and energy-efficient systems. The coil coating further enhances the durability and weather resistance of the aluminum, ensuring long-term performance in different environmental conditions. In conclusion, coil-coated aluminum coils have vast and diverse potential applications, ranging from construction and transportation to appliances, signage, packaging, and the energy industry. The combination of excellent properties, including lightweight, durability, weather resistance, and aesthetic appeal, make coil-coated aluminum coils a preferred choice in numerous sectors.

- Q: Can aluminum coils be used in the production of chemical storage tanks?

- Yes, aluminum coils can be used in the production of chemical storage tanks. Aluminum is a durable and corrosion-resistant material, making it suitable for containing various chemicals. Additionally, its lightweight nature allows for easier handling and installation of the storage tanks.

- Q: Are aluminum coils suitable for marine environments?

- Yes, aluminum coils are suitable for marine environments. Aluminum has excellent corrosion resistance properties, making it a popular choice for marine applications. It forms a protective oxide layer that prevents further corrosion, making it ideal for withstanding the harsh saltwater and humid conditions found in marine environments. Additionally, aluminum coils are lightweight, durable, and easy to maintain, making them a reliable option for marine applications.

- Q: Are aluminum coils easy to install?

- Yes, aluminum coils are generally easy to install. They are lightweight and flexible, which makes them easier to handle and maneuver during installation. They can be easily cut and shaped to fit the specific requirements of the installation, and they are often available in pre-cut sizes, further simplifying the installation process. Additionally, aluminum coils are typically designed with features such as interlocking edges or snap-on connectors, which make it easier to join multiple coils together or connect them to other components. Overall, with the right tools and basic knowledge of HVAC installation, aluminum coils can be installed relatively easily.

- Q: What are the various classifications of aluminum coil grades?

- <p>Aluminum coils are classified into different grades based on their composition and properties. The most common grades include 1000 series (99% pure aluminum), 3000 series (aluminum-manganese alloys), 5000 series (aluminum-magnesium alloys), and 6000 series (aluminum-silico-magnesium alloys). Each series has specific characteristics, such as corrosion resistance, formability, and strength, which determine their suitability for various applications like construction, transportation, and packaging. Additionally, there are 2000 series (aluminum-copper alloys), 4000 series (aluminum-silicon alloys), 7000 series (aluminum-zinc-magnesium alloys), and 8000 series (other alloys), each with unique properties and applications.</p>

Send your message to us

PVDF PE Coated Color Aluminum Coil for Gutter Machine ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords