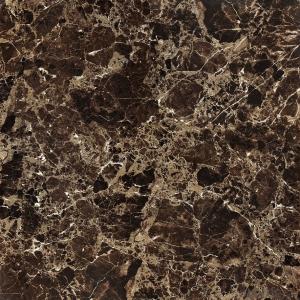

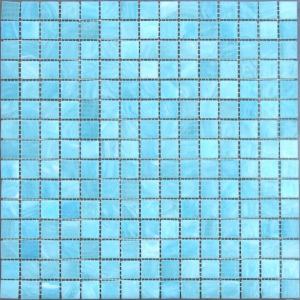

Full Polished Glazed Porcelain Tile CMAX-WTDE001

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Brief Introduction

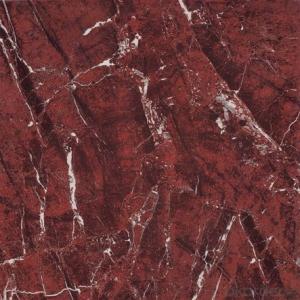

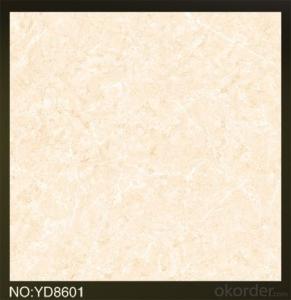

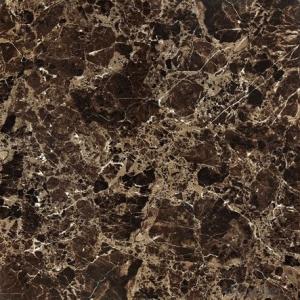

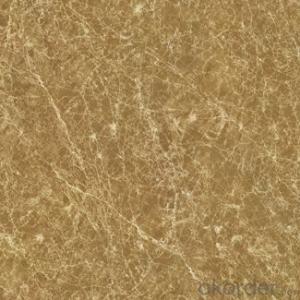

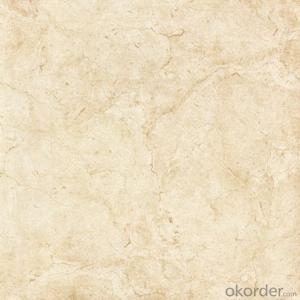

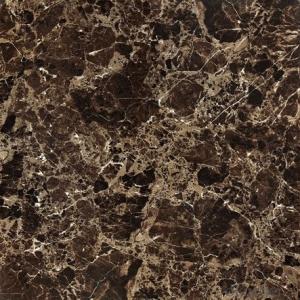

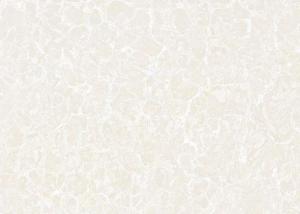

Full Polished Glazed Porcelain Tile CMAX-WTDE001 is a very popular color in the present market. Just like other models, it could be used for interior floor for apartment, villa, super market as well as other public areas, due to its stone like surface, being high glossy and clean, homogeneous color shade as well as the reasonable price compared with natural stones.

Product Features

Full Polished Porcelain Tile, high glossy

Grade AAA available only

Strict quality control system on color shade, deformation, anti-pollution, surface glossy degree as well as packing

Much more competitive price

Standard export packing: Pater Carton+ Wooden Pallet

Fast production arrangement

OEM service could be offered based on the actual requirement

Comprehensive marketing support on samples, catalogues as well as carton designing

Professional sales team available for the whole order operation process

Product Specification

Tile Type: Full Polished Glazed Porcelain Tile

Quality standard: GB/T4100-2006, ISO13006, ISO9001

Water Absorption Rate: 《0.5%

Breaking Strength: 》 1800 N

Rupture Modulus: 》40 MPa

Length and Width Tolerance: ±0.1%

Surface Smoothness: ±0.15%

Edge Straightness: ±0.15%

Wearing Strength: 《1600 mm3

Glossiness: 》 90 Degree

Resistance to Chemical: Class UA

Resistance to Staining: Class 3.

Packing Information (For 27.5 Tons heavy 20’Fcl)

For 600x600mm, 4pcs/Ctn, , 35KgS/Ctn, 36 Ctns/Pallet, 780 Ctns/20’Fcl, 1123.2 m2/20’Fcl

For 800x800mm, 3pcs/Ctn, 56Kgs/Ctn, 28 Ctns/Pallet, 500 Ctns/20’Fcl, 960 m2/20’Fcl

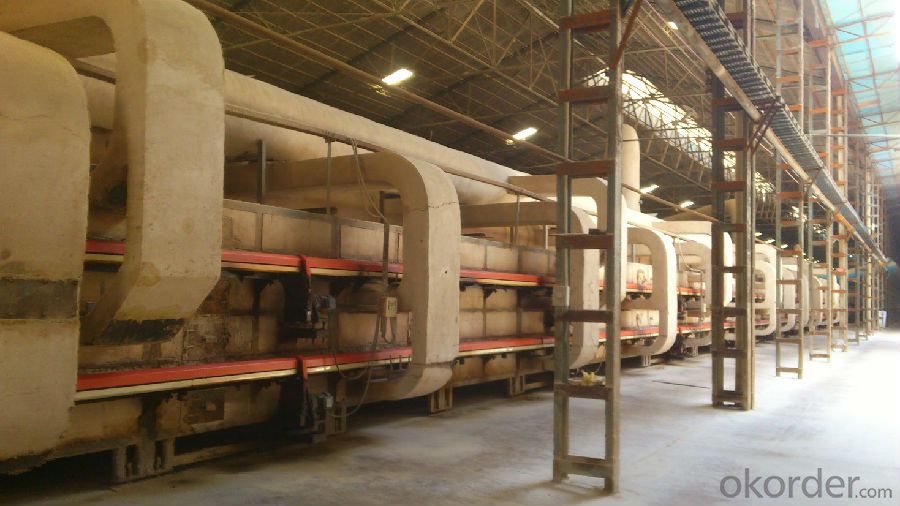

Production Line & Package

FAQ

1. For Full Polished Glazed Porcelain Tile, what is the difference from polished porcelain tile?

—— For full polished porcelain tile, there is a special glaze layer on the tile surface, while for polished porcelain tile, there is no glaze layer.

2. What is the MOQ for this tile?

—— Normally the MOQ is one 20’ container. For those models whose production could be arranged frequently, we could mix 2 or 3 models in one container.

3. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton. If the order quantity is over 5 containers, we could print the carton of client’s design for the final packing.

4. What is the delivery time after we paid the deposit?

—— Normally, we shall get all items ready for loading within 3 weeks after we get the deposit or the formal Letter of Credit. For orders which demand cutting job, it will take a longer time.

5. For the delivery term, could you go with CFR our port?

—— Yes, of course. We have very good relationship with those big shipping company, such as COSCO, MSC, HPL etc. We have a very professional logistic team to arrange the shipping issue well.

6. Could you company supply polished porcelain tile?

—— Yes. We could supply various kinds of polished porcelain tile, with size 60*60, 80*80, 100*100 and 60*120.

7. Could you put some samples in the container of our orders?

—— Yes. We’d like to offer free samples in the containers to our clients, with a certain quantity of different models.

8. Could we be your exclusive agent in our country?

—— Possibly. For some countries we are hoping to find a proper partner in working market together. For sure we need to have a good talking for the details.

9. Could we arrange the our own QC to check the items before container loading?

—— Yes, of course. Your quality checking will be welcome all the times.

- Q: I need tips on how to install tiles around bathroom walls. I have the walls up and taped. Now what??? I leveled and drew a line under the window cell horizontal and vertical. 1) Do I start tiling from the tub up?2) How do I seal - or do I have to seal the tiles (Ceramic tiles 4x4)?3) What type of sealer should I use? Please give me a name that I can easily find @HD or loews.

- My very strong opinion on this matter is to go to Lowe's or HD during a weekday morning, when they're not too busy. Get a handy-dandy little book so you have it with you as you go. Ask the cute lil helper at the store to help you with all you will need. Yes, you will need to seal the grout - they can find the best sealer, the best grout, the whole nine yards. Good luck on your project

- Q: How to calculate the area of the toilet and kitchen tiles

- Wall, then the first to calculate the area of the wall, and then see what type of brick you buy, if it is 30x45, that is 30x45 =? And then divided by 10000 to get that number is your product to use a few pieces of brick, and then multiplied by the number of square meters, tiles is the same algorithm

- Q: I live in a single-level ranch style house but on a concrete pad. I am re-tiling the kitchen floor. Upon removing the old tile, I discovered a 15 lb. felt pad had been glued to the floor; on top of this pad was thin set; then the tile. I live in Bakersfield, CA which is a dry and arrid climate.

- As long as it's not ceramic tiles, if so, I'd tear off the tiles. If it's linoleum, make sure you have a good subflooring and knock yourself out! Fallow the recommendations of the spacing around the walls AND take the time to bring in your flooring and let it in the room it'll be used for at least 24 hrs to dilate with the room's temperature and humidity. Don't pile all the packs in one corner, they need to breathe.

- Q: I‘m installing a kitchen back splash of 1 x 1 glass tile. Right now there is drywall where the tile will be. I‘ve read that it is better to use cement backing board as a substrate. Is this really necessary or can I just use thin-set to mount the tile directly to the drywall and then grout as usual? Thanks for your help!

- Drywall is a suitable substrate for the glass tile. You want to make sure that the drywall is clean, wipe it down with mineral spirits. Next you will want to mark a level line. 1 glass tiles are fairly heavy when mounted on a 12 mesh sheet, and will tend to sag. This level line will be the top mark of your lower sheet. After you have your line either drawn or chalked, you will want to use a glass tile specific mortar, such as Mapei Adesilex P10. This is a non sagging mortar with a bright white color to allow the glass color to pop. Be sure to follow the mixing instruction to get the best performance, and only mix as much as you can use in a short period of time. Glass tiles are great for backsplashes because of the ease of maintenance, so make sure to use a grout that give you the same performance. Mapei has Opticolor grouts which are stain-free, but offer the same installation as regular grout. Last bit of advice is to be patient, work at your own pace, and step back every other sheet to make sure it looks good as you go.

- Q: I need to measure my tiles to get them cleaned but they all need the size in squares how do i do that, thanks in advance

- In constrution terms a square is 100 sq ft.But that's pretty much only used for roofs.I think what you need here is a measurement in square feet To get it just measure the floor both ways and multiply. I.e. If the room measures 10 Ft X 10 ft then you have 100 sq ft

- Q: We purchased a 12 year old house and some of the ceramic floor tiles are cracked and need to be replaced. Where can you find old ceramic tile patterns? Do I have to replace the entire area?

- FINDING OLD TILES ARE LIKE FINDING OLD CAR PARTS slim and none,but don.t dis pair remove one of the old broken or not and take it to local tile only store home depot probably will be of little help as they know their currant supply and only supplier.if all else fails find a complementary style and size and create a new pattern removing the broken and possibly a few not so broken create a new design or bite the bullet.careful in the removal of tiles near tile you want to keep remove grout surrounding the tile you want to remove before you break it out the grout will transfer the impact of a hammer to surrounding tiles breaking more than you want

- Q: I want to buy six glass tiles for my science project but i don‘t know where to buy them. There are windows for sale but I don‘t want to use hundreds of dollars for a window.

- While okorder

- Q: Do they make that large of a difference? I am tiling my entire house, but can‘t find 1200 sq. ft. of the same tile dye number. I thought i could use different numbers in the bedroom. Is it going to be that noticable?

- Just buy a bunch of cases and mix them all up. See if theres an arrow on the back of the tile so you have them all pointed in the same direction.

- Q: Hello,Trying to decide on tile for living area. What is the difference between ceramic and porcelain tiles? What price is reasonable for installation of the tile?

- Not sure of price, but we just had to choose tile flooring last year. Porcelain is more durable and much less likely to crack if something were dropped on it, so, depending on your usage/traffic, you may want to consider. We found the price comparable between the two options and went with the porcelain.

- Q: Chengdu tiles wholesale market

- Hello, do not know if you have a shop now? You can come to Zibo Fortune City side of the investigation, where the flowers and prices are more advantages.

Send your message to us

Full Polished Glazed Porcelain Tile CMAX-WTDE001

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches