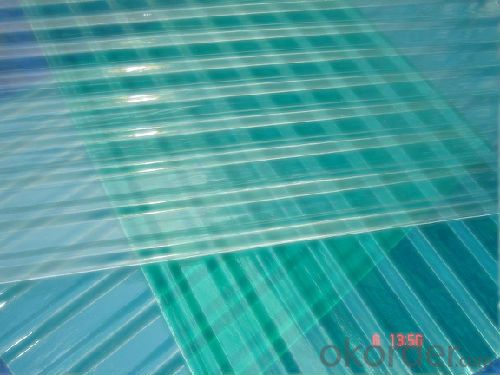

FRP Roofing Panel - Reinforced Glass Fiber Corrugated Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

products are resistant to the corrosion of gas and liquid of acids, alkalis, salt, and organic solvent so that they can avoid the problem of rusting steel and rotten wood.

2.Characteristics

Light weight and high intensity

fiberglass products are molded through the solidification of fiberglass and resin under high temperature. Its density is only one quarter of that of steel, and two-thirds of that of aluminum. But its intensity is ten times that of PVC, exceeding the aluminum products and reaching the level of common carbon steel. Due to its light weight, the products require less base support and possess the features of easy installation and low costs.

Inflaming Retarding

The common oxygen index of common fiberglass products is above 32 (according to GB8924). By design, the flame spreading index of the high inflaming retarding ethylene products is below 10, which meets the requirements of engineering fire resistance for safety.

Collision Resistance and Fatigue Resistance

fiberglass products can resist collision and keep the original shape after repeated bending so as to be used as spring.

Age Resistance

The normal longevity is more than 20 years. The research result shows that the intensity will still retain more than 85% after 20 years’ exposure to the atmosphere.

3.Application

Good appearance and Easy Maintenance

The color slurry offiberglass products is mixed with resin to make the color bright and difficult to fade. No painting is needed on the surface which is clean after washing.

4.FAQ

Packaging & Delivery

Packaging Details: | Poly bag, then loading into carton box |

Delivery Detail: | 20 days after confirm order |

- Q: Can FRP roofing panels be used for carports or parking structures?

- Carports and parking structures can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess qualities that make them an ideal selection for outdoor structures, as they are lightweight, resilient, and resistant to corrosion. They are capable of enduring harsh weather conditions, including extreme temperatures, UV radiation, and heavy rainfall. Moreover, installing and maintaining FRP panels is a simple task, ultimately reducing the overall expenses and labor involved in constructing carports or parking structures. Their adaptability allows for customization in terms of color, profile, and thickness, further enhancing their applicability for such purposes. In conclusion, FRP roofing panels offer a dependable and cost-efficient choice for carports and parking structures.

- Q: Are FRP roofing panels eco-friendly?

- Yes, FRP roofing panels can be considered eco-friendly. They are made from a combination of fiberglass and resin, which are durable and long-lasting materials. This means that they require less frequent replacement, reducing waste and the need for additional resources. Additionally, FRP panels are lightweight, which reduces the energy required for transportation and installation. Furthermore, they are also recyclable, allowing for proper disposal and reuse at the end of their lifespan. Overall, FRP roofing panels offer several environmentally friendly features that make them a sustainable choice.

- Q: What are the FRP lighting panels and their common classification and specifications?

- FRP lighting board for a wide range of uses: industrial buildings, roofing, wall lighting, agricultural vegetable greenhouses insulation, lighting, public stadiums, roof lighting, special requirements of buildings, fire protection, anti-corrosion, heat insulation and other places.

- Q: Are FRP roofing panels resistant to warping or sagging over time?

- FRP roofing panels are indeed highly resistant to warping or sagging over time. The fiberglass reinforcement present in these panels ensures remarkable strength and dimensional stability, effectively preventing any substantial alterations in shape or sagging caused by environmental factors or the weight of the panel itself. Moreover, the low coefficient of thermal expansion exhibited by FRP panels means they experience minimal expansion or contraction with temperature fluctuations, further decreasing the likelihood of warping or sagging. Consequently, FRP roofing panels emerge as a dependable and long-lasting option.

- Q: Are FRP roofing panels prone to discoloration over time?

- FRP (Fiberglass Reinforced Plastic) roofing panels are generally not prone to discoloration over time. These panels are known for their excellent resistance to UV rays, which helps prevent fading or yellowing that can occur with other materials. However, it is important to note that the extent of discoloration also depends on the quality of the FRP panels and the environment in which they are installed. If the panels are of low quality or exposed to harsh weather conditions, such as extreme heat or excessive moisture, there is a possibility of some discoloration occurring over an extended period of time. To minimize the risk of discoloration, it is recommended to choose high-quality FRP roofing panels and properly maintain and clean them regularly.

- Q: Can FRP roofing panels be used for public transportation stations or terminals?

- FRP roofing panels are an ideal option for public transportation stations or terminals. These panels are widely used in construction for their strength, durability, and ability to resist corrosion and weathering. They are lightweight and simple to install, making them perfect for situations where speedy installation is vital, such as public transportation facilities. Moreover, FRP panels can be designed to provide exceptional insulation and noise reduction, ensuring a comfortable experience for commuters. In conclusion, FRP roofing panels offer a cost-effective and dependable solution for public transportation stations or terminals.

- Q: Can FRP roofing panels be used in airports or transportation hubs?

- Yes, FRP roofing panels can be used in airports or transportation hubs. FRP (Fiberglass Reinforced Plastic) roofing panels are lightweight, durable, and resistant to corrosion and UV exposure. These qualities make them suitable for use in high-traffic areas like airports and transportation hubs where durability, ease of installation, and low maintenance are important factors. Additionally, FRP panels can provide excellent insulation and are fire-resistant, making them a safe and efficient choice for such facilities.

- Q: Can FRP roofing panels be used in high-traffic areas?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in high-traffic areas. FRP panels are known for their durability and strength, making them suitable for areas with heavy foot traffic. They are designed to withstand harsh weather conditions, including extreme temperatures, UV radiation, and high winds, making them ideal for outdoor environments. Additionally, FRP panels are resistant to corrosion, chemicals, and impact, making them highly durable and long-lasting. These characteristics make FRP roofing panels a popular choice for high-traffic areas such as commercial buildings, industrial facilities, sports stadiums, and public spaces where durability and performance are essential.

- Q: Can FRP roofing panels be installed on both residential and commercial buildings?

- Yes, FRP roofing panels can be installed on both residential and commercial buildings. FRP panels are versatile and can be used in various applications, including homes, offices, warehouses, and industrial buildings. They offer durability, lightweight construction, and resistance to weathering, making them suitable for both residential and commercial roofing needs.

- Q: Are FRP roofing panels resistant to warping due to heat?

- Yes, FRP roofing panels are highly resistant to warping due to heat. The unique composition of fiberglass reinforced plastic (FRP) makes these panels highly durable and stable, allowing them to withstand high temperatures without warping.

Send your message to us

FRP Roofing Panel - Reinforced Glass Fiber Corrugated Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords