FRP Roofing Panel - FRP Fiberglass Glassfiber Corrugated Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

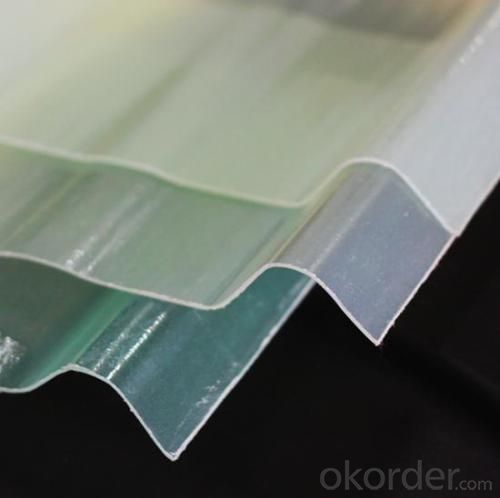

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions.

FEATURES

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%.

2) Weather resistant and Self-clean ability.

3) Excellent yellowness resistance.

4) Strong impact resistant and low bending rate.

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

SPECIFICATIONS

| Items | Data |

| Tensile Strength | 122.8Mpa |

| Tensile Modulus | 8610Mpa |

| Flexural Strength | 219.9mPA |

| Flexural Modulus | 8210Mpa |

| Barcol Hardness | 47 |

| Izod Impact | 80.4kj/m2 |

| Thermal Expansivity | 2.4X10-5 °C-1 |

| Distortion Termperature | >230°C |

| Water Absorption | 0.16%/24hrs@25°C |

| Gravity | 1.5g/cm3-1.9g/cm3 |

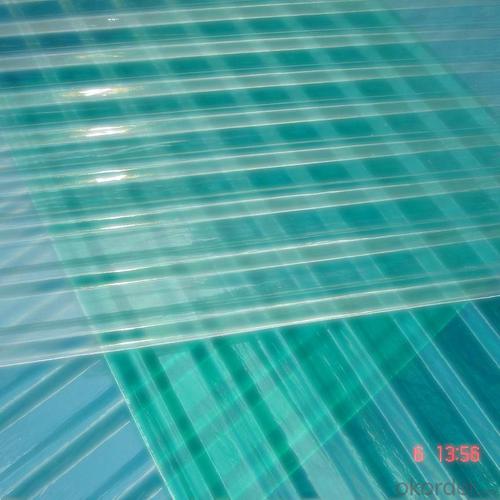

PICTURES

- Q: Can FRP roofing panels be used for skylights with opening mechanisms?

- FRP roofing panels have the capability to serve as skylights with opening mechanisms. These lightweight and long-lasting panels made of Fiberglass Reinforced Plastic offer exceptional light transmission, making them an ideal choice for skylights. They can be customized to include an integrated opening mechanism, providing the option for ventilation and control over natural light. The opening mechanisms can be operated manually or automatically, depending on the desired design and specifications. To guarantee compliance with safety and engineering standards, it is essential to seek guidance from a professional or manufacturer when selecting FRP roofing panels for skylights with opening mechanisms.

- Q: Are FRP roofing panels suitable for commercial kitchens or industrial facilities?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for commercial kitchens and industrial facilities. FRP panels offer several advantages that make them a popular choice for these applications. Firstly, FRP panels are highly durable and resistant to corrosion, chemicals, and moisture. This makes them ideal for environments such as commercial kitchens where there is a high risk of exposure to harsh chemicals and frequent cleaning. Additionally, FRP panels are lightweight yet strong, making installation and handling easier and more cost-effective. They also have excellent thermal insulation properties, which can help regulate temperature and reduce energy costs in industrial facilities. Furthermore, FRP panels are available in various colors, finishes, and profiles, allowing for customization to suit specific design requirements. They can be easily integrated with other roofing systems and accessories, such as skylights and vents, providing flexibility in design and functionality. Overall, the durability, resistance to corrosion and chemicals, lightweight nature, thermal insulation properties, and customization options make FRP roofing panels a suitable choice for commercial kitchens and industrial facilities.

- Q: Are FRP roofing panels resistant to bird damage?

- FRP roofing panels, also known as fiberglass reinforced plastic roofing panels, are generally resistant to bird damage. The durable nature of FRP makes it less susceptible to scratches, pecks, or punctures caused by birds compared to other roofing materials such as shingles or metal. However, it is important to note that no material is completely impervious to bird damage. In rare cases, aggressive bird behavior or large birds with strong beaks may still be able to cause some damage to FRP roofing panels. To minimize the risk of bird damage, it is advisable to make sure that the panels are properly installed, regularly inspected, and any potential bird entry points are sealed off. Additionally, taking preventive measures like using bird deterrent devices or netting can further discourage birds from perching or nesting on the roof, thereby reducing the chance of damage.

- Q: Can FRP roofing panels be used for walkways or catwalks?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for walkways or catwalks. FRP panels are lightweight, durable, and have excellent strength properties, making them suitable for various industrial and commercial applications, including walkways and catwalks. These panels are resistant to corrosion, chemicals, and UV rays, making them ideal for outdoor use. Additionally, FRP panels can be customized to fit specific design requirements, making them versatile for different walkway and catwalk installations. Overall, FRP roofing panels are a cost-effective and reliable option for creating safe and functional walkways and catwalks.

- Q: Are FRP roofing panels easy to repair?

- Repairing FRP roofing panels is relatively easy. The lightweight and durable nature of these panels makes them easy to handle and work with during the repair process. They are also resistant to corrosion, mold, and mildew, reducing the need for extensive repair. To repair FRP roofing panels, the damaged area needs to be cleaned, and any loose material or debris should be removed. Then, a suitable patching material or adhesive is applied to seal the damaged section. Depending on the extent of the damage and the individual's expertise, this can be done by a homeowner or a professional contractor. It's important to note that the ease of repair may vary depending on the specific type and brand of FRP panel used. Some manufacturers may offer repair kits or provide specific instructions for their products, which can simplify the repair process even more. Overall, with proper maintenance and timely repairs, FRP roofing panels can provide long-lasting protection for various applications.

- Q: Are FRP roofing panels available in different sizes?

- Yes, FRP roofing panels are available in various sizes to suit different roofing needs and specifications.

- Q: Are FRP roofing panels prone to cracking or warping over time?

- FRP roofing panels, renowned for their durability and resistance to cracking or warping, are constructed using a blend of fiberglass and plastic resins. This unique combination grants them exceptional strength and stability. One of the key benefits of FRP roofing panels lies in their ability to endure harsh weather conditions, including extreme temperatures, strong winds, and heavy rainfall. Unlike other roofing materials, FRP panels do not significantly expand or contract with temperature changes, thereby averting cracking or warping. Moreover, FRP panels are engineered to be lightweight yet robust, rendering them less susceptible to damage from external forces. This strength and rigidity enable the panels to maintain their shape and integrity over time, further minimizing the risk of cracking or warping. Nevertheless, it is crucial to acknowledge that the longevity and durability of FRP roofing panels can be influenced by various factors, such as the quality of materials, proper installation, and regular maintenance. Inferior or substandard panels may exhibit a greater propensity for cracking or warping. Similarly, incorrect installation or neglecting necessary maintenance, such as keeping the panels free of debris, can compromise their structural integrity. In conclusion, when FRP roofing panels are manufactured, installed, and maintained correctly, they possess a well-established reputation for being highly resistant to cracking or warping over time. Nonetheless, it is always prudent to seek guidance from professionals and adhere to the manufacturer's guidelines to ensure optimal performance and longevity of the panels.

- Q: Can FRP roofing panels be used for outdoor arenas or stadiums?

- FRP roofing panels are perfectly suitable for outdoor arenas or stadiums. Their durability, strength, and resistance to different weather conditions make them an excellent choice for outdoor applications. These panels are lightweight, yet they offer exceptional impact resistance, which is crucial for areas with high traffic like stadiums and arenas. Moreover, FRP panels resist UV rays, moisture, and chemicals, ensuring their longevity in outdoor environments. Their versatility allows them to be used in various designs, including curved or domed roofs, providing practical and aesthetic benefits to the structures. In conclusion, FRP roofing panels are a dependable and cost-effective solution for outdoor arenas or stadiums due to their weather resistance, durability, and design flexibility.

- Q: Can FRP roofing panels be used for noise insulation in buildings?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for noise insulation in buildings. FRP panels have excellent sound absorption properties due to their ability to dampen vibrations and reduce noise transmission. They can effectively reduce the impact of external noise sources such as traffic or airplanes, as well as internal noise sources like machinery or HVAC systems. Additionally, FRP panels are lightweight and easy to install, making them a cost-effective solution for noise insulation in both commercial and residential buildings.

- Q: Can FRP roofing panels be installed on boat docks or marinas?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on boat docks or marinas. FRP panels are known for their durability, lightweight nature, and resistance to corrosion, making them suitable for these applications. They provide excellent protection against weather elements and can withstand the harsh marine environment, making them a reliable choice for boat docks and marinas.

Send your message to us

FRP Roofing Panel - FRP Fiberglass Glassfiber Corrugated Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords