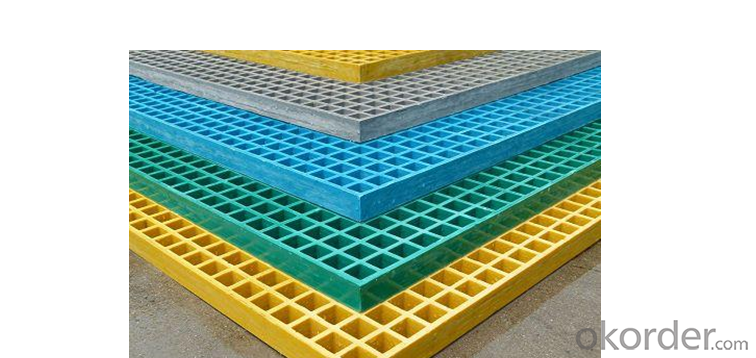

FRP Pultrusion Profiles - High Strength, Corrosion Resistant and Fire Resistant Gratings with Modern Shape & Great Color

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

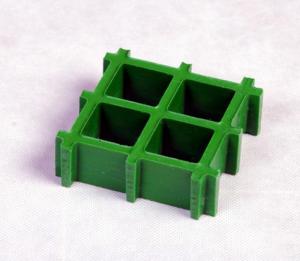

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

- Light Weight & High Strength

- Electrical Insulating

Aging Resistance

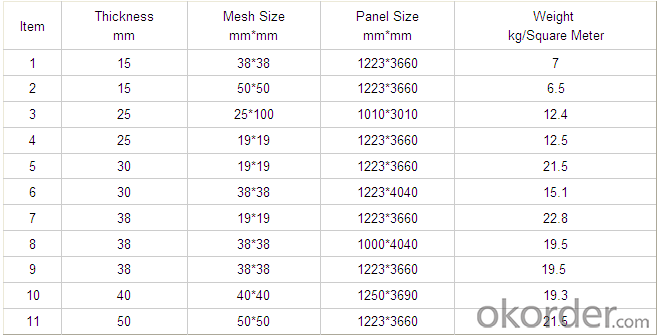

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

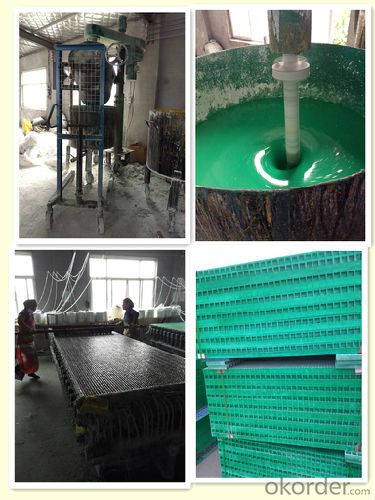

PROCESS

FACTORY

- Q: Are FRP pultrusion profiles resistant to oil and grease?

- FRP (Fiber Reinforced Plastic) pultrusion profiles are generally known for their excellent resistance to oil and grease. The combination of fibers, typically glass or carbon, with a polymer resin matrix results in a material that is inherently resistant to many chemicals, including oil and grease. This resistance is attributed to the non-reactive nature of the polymer resin, which prevents the oil or grease from penetrating the material and causing damage. Additionally, the pultrusion manufacturing process used to produce FRP profiles further enhances their resistance to oil and grease. During the pultrusion process, the fibers are impregnated with the resin and then pulled through a heated die, where the resin is cured. This creates a strong, uniform material with a dense surface that is less porous and more resistant to chemical penetration. It is important to note that the specific resistance of FRP pultrusion profiles to oil and grease can vary depending on the type of resin used and the specific application conditions. In some cases, specialized resin formulations can be used to further enhance the oil and grease resistance of FRP profiles, ensuring suitability for even more demanding environments. Overall, FRP pultrusion profiles are generally considered to be highly resistant to oil and grease, making them an excellent choice for applications where exposure to these substances is expected. However, it is always recommended to consult with the manufacturer or supplier to ensure that the specific FRP profile being used is appropriate for the intended application and chemical exposure.

- Q: Can FRP pultrusion profiles be used in wastewater treatment facilities?

- Yes, FRP pultrusion profiles can be used in wastewater treatment facilities. FRP (Fiber Reinforced Plastic) pultrusion profiles are known for their high strength, corrosion resistance, and durability, making them suitable for various applications, including in harsh environments like wastewater treatment facilities. These profiles can be used for constructing structures, such as walkways, handrails, grating, and tanks, as well as for reinforcing or replacing traditional materials, such as steel or concrete, in different components of the facility. The corrosion resistance of FRP pultrusion profiles ensures their longevity and reduces maintenance costs, making them a viable option for wastewater treatment facilities.

- Q: Are FRP pultrusion profiles resistant to ultraviolet radiation?

- FRP pultrusion profiles possess inherent resistance to ultraviolet (UV) radiation. This is due to the utilization of materials like fiberglass and resins in FRP profiles, which naturally offer UV resistance. The manufacturing process involves impregnating reinforcing fibers with a UV-resistant resin matrix and subsequently curing them. This combination of materials and production technique guarantees that FRP pultrusion profiles can endure extended exposure to UV radiation without significant deterioration or loss of mechanical properties. Consequently, FRP pultrusion profiles are widely employed in outdoor sectors like construction, infrastructure, and marine industries where UV resistance is imperative. Nevertheless, it is crucial to acknowledge that the level of UV resistance may vary depending on the specific composition of the FRP profile and the quality of the manufacturing process. Therefore, it is always advisable to refer to the manufacturer's specifications and guidelines for the particular product being used to ensure its suitability for UV-exposed environments.

- Q: Are FRP pultrusion profiles resistant to caustic solutions?

- FRP pultrusion profiles are known for their resistance to caustic solutions. The combination of reinforcing fibers and the polymer matrix used in FRP pultrusion provides exceptional chemical resistance. Unlike traditional materials like steel or wood, which can be corroded or degraded by strong alkaline substances, FRP pultrusion profiles are highly resistant to chemical attack. This makes them suitable for industries that frequently encounter caustic solutions, such as chemical processing, wastewater treatment, and marine environments. However, it is important to refer to the manufacturer's specifications and guidelines to ensure compatibility between specific caustic solutions and the chosen FRP pultrusion profile.

- Q: What are the circumstances in which the pultrusion should be performed?

- (1) the tensile strength of high strength extruded profiles for 150 ~ 300MPa, the bending strength reached 200 ~ 300MPa, the 1000h accelerated the bending strength after aging the retention rate of up to 78%.(2) the deformation rate is low. The length of the glass reinforced plastic pultruded section is accelerated by 1000h and the width change rate is +0.03%. The width change rate is -0.07%.. Therefore, the geometry and size of the product made of this pultruded section can be stable for a long time

- Q: Can FRP pultrusion profiles be used in the production of electrical busbars?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the production of electrical busbars. FRP pultrusion profiles are known for their excellent electrical insulation properties, high strength-to-weight ratio, and corrosion resistance. These characteristics make them suitable for various electrical applications, including busbars. FRP pultrusion profiles offer superior electrical insulation compared to traditional metal busbars, reducing the risk of electrical shock and short circuits. Additionally, their high strength-to-weight ratio allows for the production of lightweight busbars that can handle high electrical currents without sacrificing structural integrity. Furthermore, FRP pultrusion profiles have excellent resistance to corrosion and chemicals, making them ideal for use in harsh environments, such as chemical plants or outdoor installations. They are not susceptible to rust or degradation, ensuring the longevity and reliability of the electrical busbars. Overall, FRP pultrusion profiles provide a cost-effective and efficient solution for the production of electrical busbars, offering enhanced electrical insulation, strength, and corrosion resistance compared to traditional metal alternatives.

- Q: Can FRP pultrusion profiles be customized according to specific requirements?

- Yes, FRP pultrusion profiles can be customized according to specific requirements. Pultrusion is a manufacturing process that allows for the creation of complex shapes and sizes, making it possible to tailor the FRP profiles to meet specific design and performance criteria. This customization can include modifications in dimensions, reinforcement types, resin systems, color, surface finish, and various other parameters to ensure they meet the desired specifications and needs of the application.

- Q: Are FRP pultrusion profiles resistant to mold and mildew?

- FRP pultrusion profiles are known for their ability to resist mold and mildew. Made from a composite material consisting of a reinforced polymer matrix with fibers, usually glass fibers, FRP is unlike organic materials like wood or traditional plastics because it does not create a suitable environment for mold and mildew to thrive. The properties inherent in FRP, such as its non-porous nature and resistance to moisture absorption, contribute to its exceptional resistance to mold and mildew. Moreover, FRP pultrusion profiles are often manufactured with a smooth and glossy surface, further discouraging the growth of mold and mildew. In addition, FRP is chemically inert, meaning it does not react with most substances. This quality makes FRP profiles highly resistant to chemical attacks that could promote the growth of mold and mildew. Consequently, FRP pultrusions are frequently utilized in environments with high moisture and humidity levels, including bathrooms, swimming pools, and outdoor applications. Nevertheless, it is crucial to recognize that while FRP is resistant to mold and mildew, it is not entirely impervious. In extreme conditions where moisture levels remain consistently high and proper maintenance is neglected, there is still a possibility of mold and mildew growth. To ensure the longevity and resistance of FRP pultrusion profiles to mold and mildew, regular cleaning and maintenance are recommended.

- Q: Can FRP pultrusion profiles be used in automotive applications?

- Yes, FRP pultrusion profiles can be used in automotive applications. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. Additionally, FRP pultrusion profiles can withstand harsh environmental conditions, making them suitable for various automotive components, including body panels, structural supports, and interior parts.

- Q: Can FRP pultrusion profiles be used in the construction of water slides?

- Yes, FRP pultrusion profiles can be used in the construction of water slides. FRP stands for Fiber Reinforced Polymer, which is a composite material that offers several advantages for water slide construction. Firstly, FRP pultrusion profiles are lightweight yet incredibly strong, making them ideal for creating the structural components of water slides. These profiles have high strength-to-weight ratios, meaning they can withstand the dynamic loads and forces experienced in water slide applications without adding excessive weight to the structure. Secondly, FRP pultrusion profiles are highly resistant to corrosion, which is essential for water slide construction. Water slides are constantly exposed to water, chemicals, and harsh weather conditions, which can cause traditional materials like steel to corrode and degrade over time. FRP profiles, on the other hand, are inherently corrosion-resistant, ensuring the longevity and durability of the water slide. Additionally, FRP pultrusion profiles offer design flexibility. They can be customized to various shapes and sizes, allowing for the creation of unique and exciting water slide designs. These profiles can also be easily molded, allowing for the incorporation of various features such as slides, curves, and drops to enhance the overall water slide experience. Lastly, FRP pultrusion profiles have excellent thermal insulation properties. This is beneficial for water slides as it helps maintain the temperature of the water, preventing excessive heat loss or gain. This feature enhances the comfort and enjoyment of users while reducing energy consumption for heating or cooling the water. In conclusion, FRP pultrusion profiles are well-suited for water slide construction due to their lightweight, high strength, corrosion resistance, design flexibility, and thermal insulation properties.

Send your message to us

FRP Pultrusion Profiles - High Strength, Corrosion Resistant and Fire Resistant Gratings with Modern Shape & Great Color

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords