FRP Pultrusion Profiles - FRP Gratings, Fiberglass Solid Grilles & Water-Resistant Steel Grating in Various Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

- Aging Resistance

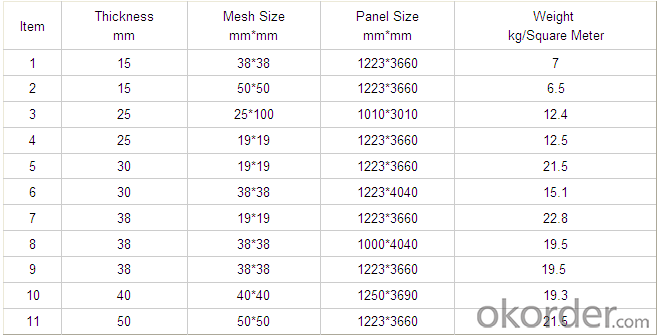

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

- long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

- All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

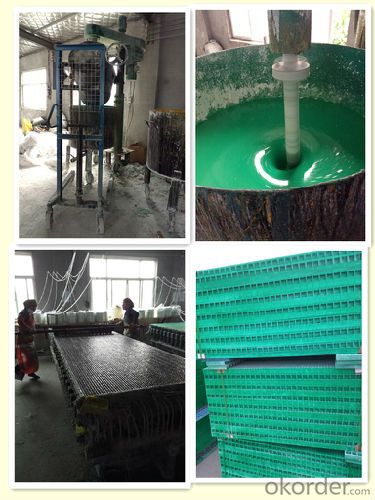

PROCESS

FACTORY

- Q: How do FRP pultrusion profiles handle cyclic loading?

- FRP pultrusion profiles are renowned for their exceptional performance in the face of cyclic loading. The pultrusion process combines unique materials and manufacturing techniques to create profiles that are highly resistant to fatigue and the effects of cyclic loading. One key factor that contributes to the outstanding performance of FRP pultrusion profiles under cyclic loading is their inherent high strength-to-weight ratio. These profiles are created using continuous fibers, typically fiberglass, that are saturated with a resin matrix. This results in a lightweight yet sturdy material that can endure repeated loading without significant degradation or fatigue. Furthermore, the pultrusion process allows for precise control over the fiber orientation and resin distribution within the profile. This ensures a consistent and uniform composition throughout the entire length of the profile. Consequently, FRP pultrusion profiles exhibit excellent load distribution characteristics, reducing stress concentrations and preventing localized failure under cyclic loading conditions. In addition, the corrosion resistance of FRP pultrusion profiles is pivotal in their ability to withstand cyclic loading. Unlike conventional materials like steel, FRP profiles are not susceptible to corrosion-related issues such as rust or pitting. This corrosion resistance guarantees that the profiles retain their structural integrity even when subjected to cyclic loading over extended periods. In summary, FRP pultrusion profiles are purposefully designed and manufactured to withstand cyclic loading conditions. Their high strength-to-weight ratio, uniform material composition, and corrosion resistance make them ideal for applications where cyclic loading is a significant concern. Whether it is in the realm of structural reinforcements, bridges, sporting equipment, or various industrial applications, FRP pultrusion profiles have consistently proven to be reliable and durable under cyclic loading.

- Q: Are FRP pultrusion profiles resistant to alkaline substances?

- FRP pultrusion profiles are known for their general resistance to alkaline substances. By using fiberglass reinforced polymer (FRP) in pultruded profiles, they acquire excellent resistance against a wide range of chemicals, including alkaline substances. The manufacturing process typically involves using a thermosetting polymer, such as polyester or vinyl ester, as the resin. This choice of resin ensures high resistance to alkaline solutions. Additionally, the fiberglass reinforcement adds strength and durability to the profiles, making them highly resistant to corrosion and degradation caused by alkaline substances. However, it is important to note that the specific resistance of FRP pultrusion profiles to alkaline substances may vary depending on the resin formulation and manufacturing process used. Therefore, it is advisable to consult the manufacturer or supplier to confirm that the profiles meet the specific resistance requirements for alkaline environments.

- Q: Are FRP pultrusion profiles resistant to hail or impact damage?

- Yes, FRP pultrusion profiles are typically resistant to hail or impact damage due to their strong and durable composition. The combination of reinforced fibers and resin matrix make them highly resistant to external forces, ensuring longevity and minimal damage in the event of hail or impact.

- Q: What is the maximum length of FRP pultrusion profiles that can be manufactured?

- The maximum length of FRP (Fiber Reinforced Polymer) pultrusion profiles that can be manufactured depends on various factors such as the specific manufacturing process, equipment capacity, and transportation limitations. In general, FRP pultrusion profiles can be manufactured in lengths ranging from a few feet to several hundred feet. However, there are certain practical limitations that need to be considered. Firstly, the length of the pultrusion profiles is often limited by the size and capacity of the pultrusion equipment used in the manufacturing process. Different pultrusion machines have varying capabilities, and their length capacities can range from a few feet to over 100 feet. Manufacturers must consider the available equipment and its limitations when determining the maximum length of the profiles they can produce. Additionally, transportation and logistical constraints may also impact the maximum length of FRP pultrusion profiles. Longer profiles can be more challenging to transport due to restrictions on road transport, shipping containers, or handling capabilities. These limitations may vary depending on the region, infrastructure, and transportation methods available. It is important to note that longer profiles may also face challenges in terms of quality control and dimensional stability during manufacturing. As the length increases, it becomes more difficult to maintain consistent mechanical properties and control the curing process effectively. Therefore, while there is no fixed maximum length for FRP pultrusion profiles, it is crucial for manufacturers to consider the technical capabilities of their equipment, transportation logistics, and quality control factors when determining the practical limit for the length of their products.

- Q: The difference between polyurethane pultruded profiles and glass reinforced plastic profiles

- Compared with other materials, pultrusion with polyurethane can produce a variety of benefits. The utility model can improve the content of the glass fiber in the product and greatly improve the strength of the product. For example, pultruded window frames made of glass fiber and polyurethane resin, the strength of the resulting window frames is 8 times higher than that of the PVC window frames, and the conductivity is 40 times lower than that of aluminum. Therefore, the insulation performance is much better.

- Q: Are FRP pultrusion profiles resistant to chemicals used in pharmaceutical packaging?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to chemicals used in pharmaceutical packaging. FRP pultrusion profiles are made of a combination of reinforced fibers and a polymer resin matrix, which provides them with excellent chemical resistance properties. The polymer resin used in FRP profiles is typically selected to be compatible with a wide range of chemicals, including those commonly used in pharmaceutical packaging. FRP profiles have been extensively used in various industries, including pharmaceuticals, due to their high chemical resistance. They are capable of withstanding exposure to a wide range of chemicals, such as acids, bases, solvents, and other aggressive substances commonly found in pharmaceutical packaging processes. This resistance helps protect the integrity of the packaging and ensures that there is no contamination or degradation of the pharmaceutical products. Additionally, FRP pultrusion profiles are also resistant to corrosion, which is another advantage in the pharmaceutical industry where aggressive chemicals may be present. This resistance to corrosion further enhances the durability and longevity of the FRP profiles, making them a reliable choice for pharmaceutical packaging applications. However, it is important to note that the specific chemical resistance of FRP pultrusion profiles may vary depending on the type and concentration of the chemicals being used. Therefore, it is recommended to consult the manufacturer or supplier of the FRP profiles to ensure their compatibility with the specific chemicals used in pharmaceutical packaging.

- Q: What are the load-bearing capabilities of FRP pultrusion profiles?

- The load-bearing capabilities of FRP pultrusion profiles are exceptional. Factors such as fiber type, arrangement, resin properties, and profile design determine their load-bearing capacity. Due to their high strength-to-weight ratio, FRP pultrusion profiles are widely used in various industries. The reinforcing fibers, made of materials like fiberglass or carbon fiber, provide the profiles with outstanding tensile and flexural strength. These fibers are embedded in a resin matrix, further enhancing the profiles' load-bearing capabilities. Manufacturers can customize the load-bearing capacity of FRP pultrusion profiles by adjusting fiber type, orientation, and resin properties. This flexibility allows for a wide range of design options, enabling engineers to optimize the profiles for different applications. Additionally, FRP pultrusion profiles have excellent corrosion resistance, making them suitable for harsh environments. Unlike steel or wood, they do not rust or rot, ensuring long-lasting durability and structural integrity. In conclusion, FRP pultrusion profiles have impressive load-bearing capabilities, making them a reliable choice for a variety of applications, including structural supports, bridges, platforms, and industrial equipment.

- Q: Can FRP pultrusion profiles be used in high-voltage applications?

- Yes, FRP pultrusion profiles can be used in high-voltage applications. FRP (Fiber Reinforced Polymer) materials are known for their excellent electrical insulation properties, making them suitable for high-voltage environments. Additionally, FRP pultrusion profiles offer advantages such as high strength, corrosion resistance, and lightweight, making them a viable option for high-voltage applications.

- Q: What are the main uses of pultruded glass fiber reinforced plastic extrusions?

- Spend entertainment mall, this is a potential market, the development of use: fishing rod, curtain rod, umbrella frame, flagpole, stuff handle, lamp, railings, handrails and staircases, radio antenna, marinas, garden tools and accessories.

- Q: Are FRP pultrusion profiles resistant to chemicals used in food processing?

- Yes, FRP pultrusion profiles are generally resistant to chemicals used in food processing. Fiberglass reinforced plastic (FRP) is known for its excellent chemical resistance, making it suitable for various industrial applications, including the food processing industry. FRP pultrusion profiles are composed of a combination of resins and fiberglass reinforcements, which provide them with inherent resistance to a wide range of chemicals. FRP pultrusion profiles are typically resistant to acids, alkalis, solvents, and many other chemicals commonly found in food processing environments. This resistance ensures that the profiles will not corrode, degrade, or react with the chemicals, preserving their structural integrity over time. This makes FRP pultrusion profiles a reliable choice for equipment, structures, and components used in food processing facilities. However, it is important to note that the specific chemical resistance of FRP pultrusion profiles can vary depending on the resin system used in their manufacturing. Different resins offer different levels of resistance to specific chemicals. Therefore, it is crucial to select the appropriate resin formulation that matches the specific chemical environment in the food processing industry. To ensure the compatibility of FRP pultrusion profiles with the chemicals used in food processing, it is advisable to consult with the manufacturer or supplier. They can provide detailed information on the chemical resistance properties of their FRP profiles and assist in selecting the most suitable materials for the specific application. Additionally, proper maintenance and regular cleaning practices should be implemented to ensure the longevity and continued chemical resistance of FRP pultrusion profiles in food processing environments.

Send your message to us

FRP Pultrusion Profiles - FRP Gratings, Fiberglass Solid Grilles & Water-Resistant Steel Grating in Various Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords