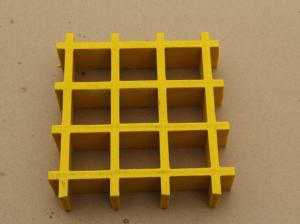

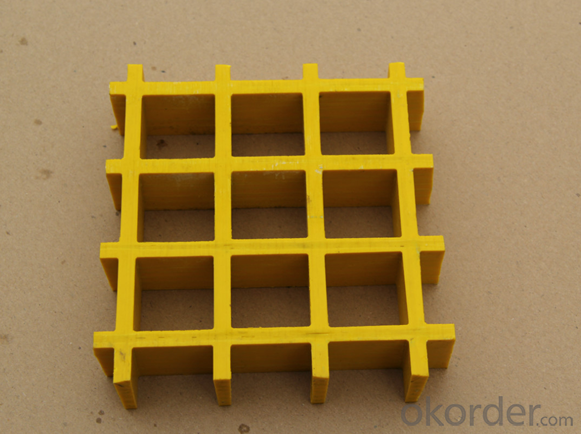

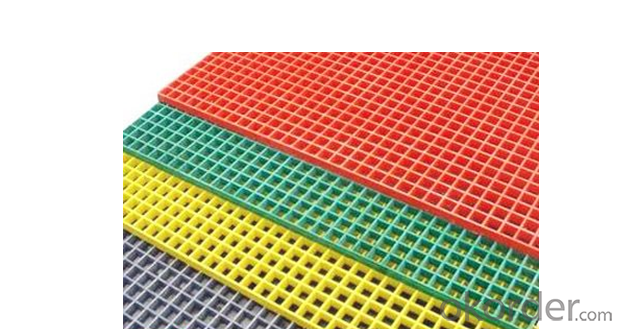

FRP Grating/ Fiberglass Solid Grille/Water Resistance Steel Grating with Various of Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

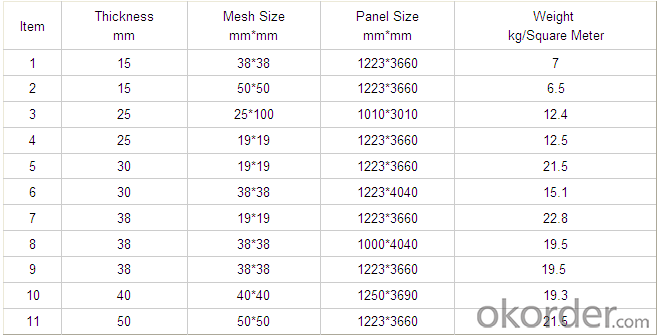

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

high strength

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

Pool railings in sewage treatment industry

Corrosive chemical industry equipment around the fence

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

3. How is the package?

Usually, we arrange the standard out-package for exporting.

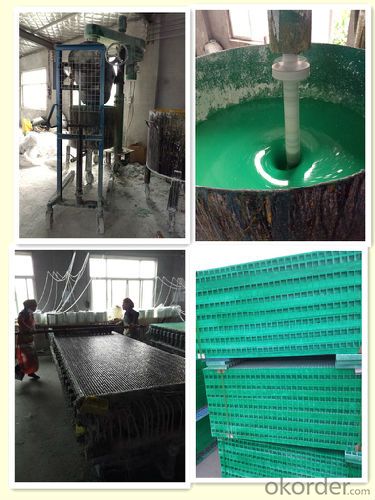

PROCESS

FACTORY

- Q: What is the lifespan of FRP pultrusion profiles?

- The lifespan of FRP pultrusion profiles can vary depending on various factors such as the quality of the material, environmental conditions, and the application they are used in. However, in general, FRP pultrusion profiles have a long lifespan and can last for several decades with proper maintenance and care.

- Q: What is the maximum length of FRP pultrusion profiles that can be manufactured?

- The maximum length of FRP (Fiber Reinforced Polymer) pultrusion profiles that can be manufactured depends on various factors such as the specific manufacturing process, equipment capacity, and transportation limitations. In general, FRP pultrusion profiles can be manufactured in lengths ranging from a few feet to several hundred feet. However, there are certain practical limitations that need to be considered. Firstly, the length of the pultrusion profiles is often limited by the size and capacity of the pultrusion equipment used in the manufacturing process. Different pultrusion machines have varying capabilities, and their length capacities can range from a few feet to over 100 feet. Manufacturers must consider the available equipment and its limitations when determining the maximum length of the profiles they can produce. Additionally, transportation and logistical constraints may also impact the maximum length of FRP pultrusion profiles. Longer profiles can be more challenging to transport due to restrictions on road transport, shipping containers, or handling capabilities. These limitations may vary depending on the region, infrastructure, and transportation methods available. It is important to note that longer profiles may also face challenges in terms of quality control and dimensional stability during manufacturing. As the length increases, it becomes more difficult to maintain consistent mechanical properties and control the curing process effectively. Therefore, while there is no fixed maximum length for FRP pultrusion profiles, it is crucial for manufacturers to consider the technical capabilities of their equipment, transportation logistics, and quality control factors when determining the practical limit for the length of their products.

- Q: How do FRP pultrusion profiles perform in electrical grounding systems?

- FRP pultrusion profiles have demonstrated promising performance in electrical grounding systems, showcasing their potential. These profiles consist of a combination of fibers, such as glass or carbon, and a polymer resin matrix. This unique composition provides them with exceptional attributes, including high strength, durability, and resistance to corrosion. One noteworthy advantage of FRP pultrusion profiles in electrical grounding systems lies in their remarkable electrical insulation properties. Unlike metals, which conduct electricity, FRP profiles possess a significantly high resistance to electrical current. This aspect renders them ideal for applications where electrical isolation is paramount. By doing so, they effectively mitigate the risks associated with electrical shock hazards and diminish the potential for short circuits. Furthermore, FRP pultrusion profiles offer superior mechanical strength while remaining lightweight. Consequently, they are easy to handle and install, leading to reduced labor costs and time consumption. Additionally, these profiles exhibit resistance against UV radiation, chemicals, and moisture, ensuring their long-term performance and durability across various environmental conditions. Another advantageous attribute of FRP pultrusion profiles pertains to their corrosion resistance. Unlike metals, which are susceptible to rust and deterioration over time, FRP profiles remain immune to corrosion. This quality renders them highly suitable for deployment in harsh or corrosive environments, guaranteeing the longevity and reliability of the electrical grounding system. Moreover, FRP pultrusion profiles exhibit non-magnetic properties, presenting an advantage in situations where minimizing or eliminating magnetic interference is crucial. This characteristic effectively prevents any disturbances to sensitive electrical equipment, thereby ensuring accurate electrical measurements. In conclusion, FRP pultrusion profiles offer a multitude of advantages in electrical grounding systems. Their exceptional electrical insulation properties, impressive mechanical strength, corrosion resistance, lightweight nature, and non-magnetic characteristics make them a reliable and efficient choice for guaranteeing the safety and reliability of electrical grounding.

- Q: Can FRP pultrusion profiles be used in the construction of pedestrian tunnels?

- Pedestrian tunnels can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. FRP is a lightweight and high-strength material that presents several advantages over traditional construction materials like steel or concrete. Corrosion resistance is a significant benefit of FRP pultrusion profiles in pedestrian tunnel construction. Unlike steel, FRP does not corrode when exposed to moisture or harsh environmental conditions. This is particularly valuable for underground structures like pedestrian tunnels, where water seepage or high humidity may pose concerns. Moreover, FRP pultrusion profiles possess exceptional mechanical properties, including high tensile strength and stiffness. Consequently, they can endure heavy loads and provide structural integrity to the tunnel. FRP's lightweight characteristic also simplifies handling and installation, ultimately reducing construction time and costs. Additionally, FRP profiles can be easily molded into various shapes and sizes, making them highly versatile for designing pedestrian tunnels. They can be tailored to meet specific project requirements, such as tunnel curvature or dimensions. This design flexibility enables innovative and efficient solutions in tunnel construction. Regarding safety, FRP pultrusion profiles exhibit high fire resistance and are non-conductive, crucial for ensuring pedestrian safety in tunnels. They also possess low thermal conductivity, providing insulation properties that help maintain a comfortable environment inside the tunnel. Overall, the utilization of FRP pultrusion profiles in pedestrian tunnel construction offers numerous benefits, including corrosion resistance, high strength, design versatility, and enhanced safety. These advantages establish FRP as an excellent choice for constructing durable and efficient pedestrian tunnels.

- Q: How do FRP pultrusion profiles handle torsion loads?

- FRP pultrusion profiles are designed to handle torsion loads effectively due to their inherent properties. The continuous fibers in the profile provide excellent resistance to torsional forces, ensuring high strength and stability. The pultrusion manufacturing process also allows for precise control over the fiber orientation, resulting in profiles that can efficiently handle torsion loads without compromising their structural integrity.

- Q: Are FRP pultrusion profiles resistant to high-pressure water jets?

- FRP pultrusion profiles have a general resistance to high-pressure water jets. Their high strength-to-weight ratio, corrosion resistance, and durability make them suitable for applications involving water and harsh environments. The pultrusion manufacturing process ensures thorough resin impregnation of the fibers, resulting in a dense composite material. This density provides high resistance to water penetration, protecting the material from damage by high-pressure water jets. Additionally, FRP pultrusion profiles exhibit excellent chemical resistance, including resistance to water. This ensures that the profiles will not degrade when exposed to high-pressure water jets for extended periods. It is important to note that the specific resistance of FRP pultrusion profiles to high-pressure water jets may vary depending on the resin and fiber combination used. To obtain detailed information about the resistance of specific profiles in a given application, it is recommended to consult the manufacturer or supplier.

- Q: Are FRP pultrusion profiles impact resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally known for their high impact resistance. The combination of reinforcing fibers, such as glass or carbon, with a polymer matrix results in a material that is inherently strong and durable. The pultrusion process further enhances the impact resistance of these profiles by aligning the fibers in the direction of the load, providing optimal strength against impacts. FRP pultrusion profiles also have a high strength-to-weight ratio, which allows them to withstand heavy impacts without significant damage or deformation. This makes them suitable for applications where impact resistance is crucial, such as in construction, transportation, and infrastructure projects. Moreover, FRP pultrusion profiles offer excellent resistance against corrosion, chemicals, and UV radiation, which further contribute to their durability and long-term performance. These profiles can maintain their impact resistance properties even in harsh environments, making them a preferred choice for various industries. However, it is important to note that the specific impact resistance of FRP pultrusion profiles may vary depending on the specific design, composition, and manufacturing process. Therefore, it is recommended to consult with the manufacturer or supplier to ensure the profiles meet the desired impact resistance requirements for a particular application.

- Q: Will the FRP section crack for a long time?

- Under normal circumstances, glass fiber reinforced plastic profiles will not appear cracking phenomenon, if there is cracking phenomenon, may be the following reasons:1, the placement method is incorrect, such as irregular, non closed section of a large number of stacked2 、 the resin content in the profile is low, filling is more (see if the section color is whiter, and more powder fall off at the same time)

- Q: What are the quality control measures for FRP pultrusion profiles?

- The quality control measures for FRP pultrusion profiles typically include visual inspection, dimensional checks, mechanical testing, and material analysis. Visual inspection ensures that the profiles are free from any visual defects such as cracks, voids, or surface imperfections. Dimensional checks verify that the profiles meet the required specifications and tolerances. Mechanical testing involves conducting various tests like flexural, tensile, and impact testing to ensure the profiles meet the required strength and performance criteria. Material analysis examines the composition and properties of the raw materials used in the pultrusion process to ensure they meet the desired standards. Overall, these quality control measures help ensure the consistent and reliable performance of FRP pultrusion profiles.

- Q: Are FRP pultrusion profiles resistant to termites?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to termites. Termites primarily feed on cellulose-based materials, such as wood, and since FRP pultrusion profiles are made of a combination of resin and glass fibers, they do not contain cellulose and therefore are not attractive to termites. This makes FRP pultrusion profiles a great alternative to traditional wooden profiles when it comes to applications where termite resistance is required, such as in building construction and outdoor structures. Additionally, FRP profiles are also resistant to rot, corrosion, and other environmental factors, making them a durable and long-lasting material choice.

Send your message to us

FRP Grating/ Fiberglass Solid Grille/Water Resistance Steel Grating with Various of Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords