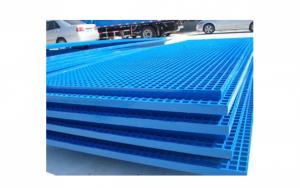

FRP Pultrusion Profiles - Solid FRP Flooring Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

GRPGratings are produced by wet moulding and hot curing in a heated mould. Thereinforcement consists of continuous fibreglass rovings in alternating layers.So the loads are distributed evenly in all directions.

Design

Regularly Moulded GRP Gratings have a polyester resinmatrix. Glass content is approximately 35%. Standard colours are green, yellowor grey, other colours are available according to RAL.

2.Characteristics

GRPGratings are produced by wet moulding and hot curing in a heated mould. Thereinforcement consists of continuous fibreglass rovings in alternating layers.So the loads are distributed evenly in all directions.

Design

Regularly Moulded GRP Gratings have a polyester resinmatrix. Glass content is approximately 35%. Standard colours are green, yellowor grey, other colours are available according to RAL.

1)corrosion/slip resistant

2) fire/impact retardant

3) high strength-to-weight ratio

4) easy to install and to maintain

3.Product Specifications

Item no. | Height(mm) | Mesh Size | Standard Panel Sizes | Bar Thickness | Open Area | Weight |

1 | 13 | 50.8×50.8 | 3660×1220 | 6.4 / 5.4 | 76% | 5.5 |

2 | 15 | 25.4×25.4 / 50.8×50.8 | 3660×1220 | 6.2 / 5 | 57% | 7.2 |

3 | 15 | 38.1×38.1 | 3660×1225 | 6.3 / 5.2 | 69% | 6.5 |

4 | 15 | 20×20 / 40×40 | 4047×1247 | 6.35 / 5.3 | 47% | 11.5 |

5 | 20 | 38.1×38.1 | 3665×1225 | 6.3 / 5 | 69% | 9.3 |

6 | 20 | 12.8×12.8×12.8 / 38.5×38.5 | 3434×970 | 7.2 / 6.4 | 27% | 18.5 |

7 | 25 | 38.1×38.1 | 3665×1225 | 6.35 / 5 | 69% | 12.3 |

8 | 25 | 40×40 | 4047×1007 | 6.35 / 5 | 70% | 12.2 |

9 | 25 | 19×19 / 38×38 | 4005×1220 | 6.4 / 5 | 44% | 15.5 |

10 | 25 | 25×100(Bearing bars to run width direction) | 3007×1009 | 9.4 / 8(length) | 67% | 13.8 |

11 | 25 | 25.4×101.6(Bearing bars to run width direction) | 3660×1220 | 7 / 5 | 67% | 13.0 |

12 | 25 | 101.6×25.4(Bearing bars to run length direction) | 3665×1225 | 7 / 5 | 67% | 13.1 |

13 | 30 | 38.1×38.1 | 4008×1525 | 6.6 / 5 | 68% | 14.6 |

14 | 30 | 40×40 | 4047×1007 | 6.6 / 5 | 69% | 14.2 |

15 | 30 | 20×20 / 40×40 | 4047×1247 | 7 / 5 | 42% | 18.1 |

16 | 30 | 12.7×12.7×12.7 / 38×38 | 4040×1220 | 7 / 5 | 30% | 23.5 |

17 | 30 | 26×26 / 52×52 | 4011×1150 | 6.5/5 | 56% | 13.6 |

18 | 38 | 38.1×38.1 | 3969×1525 | 7 / 5 | 66% | 19.2 |

19 | 38 | 40×40 | 4047×1007 | 7 / 5 | 67% | 18.8 |

20 | 38 | 152.4×25.4(Bearing bars to run length direction) | 3665×1226 | 7 / 5(length) | 68% | 20.4 |

21 | 38 | 101.6×38.1(Bearing bars to run length direction) | 3660×1220 | 7 / 5 | 76% | 14.5 |

22 | 38 | 19×19 / 38.1×38.1 | 4045×1220 | 7 / 5 | 40% | 23.5 |

23 | 38 | 20×20 / 40×40 | 4047×1247 | 7 / 5 | 42% | 22 |

24 | 40 | 40×40 | 4047×1247 | 7 / 5 | 67% | 20.0 |

25 | 40 | 220×60 | 2207×1507 | 7 / 5 | 85% | 9.5 |

26 | 40 | 20×20 / 40×40 | 4047×1207 | 7 / 5 | 42% | 23.7 |

27 | 50 | 50.7×50.7 | 3660×1225 | 8.3 / 5 | 69% | 21.5 |

28 | 50 | 50.7×50.7 | 3660×1225 | 8.8 / 5 | 68% | 23.5 |

29 | 50 | 25.35×25.35 / 50.7×50.7 | 3660×1220 | 8 / 6 | 47% | 26.0 |

30 | 50 | 152.4×38.1(Bearing bars to run length direction) | 3660×1220 | 9 / 7 | 72% | 20.8 |

31 | 50 | 38.1×38.1 | 3665×1225 | 11.5 / 9 | 48% | 40.5 |

32 | 63 | 38.1×38.1 | 3660×1220 | 12 / 9 | 47% | 52 |

33 | 63 | 38.1×38.1 | 3670×1230 | 12 / 9 | 46% |

4.FAQ

Excellent Properties

1. Corrosion and chemicalresistant

Corrosionis a major problem for metal or wooden grating, stair treads and other productsin many different industries such as chemical plants, food and beveragefactories, water and wastewater facilities, power facilities. MINCOM®grating isparticularly designed to provide safe, long-lasting, economical and worry-freesolutions in environments where chemicals and other corrosive materials attackand destroy metal or wood. According to different environmental requirements,such resins as orthophthalic polyester, is ophthalmic polyester, vinylester orphenolic are chosen as matrix material.

2.High strength-to-weight ratio

gratingmanufactured as a composite of continuous fiberglass strands and high qualityresin is integrally constructed for strength, but it is less than one-half theweight of steel grating allowing easy removal for access below floor level andinstallation with no heavy equipment and less manpower. gratings meet specified load requirements for steel and are more impactresistant than metal.

3. Fire retardant

gratinghas flame spread rating of 25 or less depending on different resin systems astested in term of ASTM E-84. Test Report can be offered upon request. Specialfire retardant requirements can also be met by adding extra additives.

4. Ergonomic

Employeesare experiencing fatigue after standing on solid concrete or heavynon-adjustable galvanized steel platforms all day, gratings are the bestsolutions to ease the strain on the backs, feet and legs of workers increasingworkers’ comfort and productivity due to its natural slight resiliency thatmakes them comfortable to stand on for a long period.

5. Slip-resistant

moldedgrating has a concave top surface for slip resistance after it is extractedfrom the mold. Should a grit surface be specified, the grit would be eitherbonded to the top of the completed grating as a secondary operation or embeddedto the top of grating before heating, both providing superior slip resistance.Diamond cover top or gritted cover top are also available upon request.

6. Anti-aging

Morethan 20 years of Life is guaranteed for MINCOM®FRP gratings.

7. Easymaintenance

Installit and forget about it. MINCOM®grating is easy to clean, its open meshespermitting debris to fall through grating panel and preventing hazardousbuildup on walking surface. MINCOM®grating is free from re-painting year afteryear not only for the inherent corrosion resistance but also for the molded-incolor and ultraviolet resistance character.

8.Safety

NON-CONDUCTIVE property makes MINCOM®grating ideallysuitable in electrically hazardous locations acting as an insulator.

NON-MAGNETIC property allows MINCOM® grating to be used in sensitiveinstallations where the inherent magnetic properties of metal grating willprove dangerous.

9. Comprehensive economical efficiency

Thecost of FRP grating is about 10% to 30% higher than that of steel grating, Butthe installation cost is about 60-80%lower! And steel grating have to be maintained everyyear. FRP grating is free of maintainence! The comprehensiveeconomical efficiency is much higher than that of steel grating.

- Q: Are FRP pultrusion profiles resistant to chemicals used in semiconductor manufacturing?

- Yes, FRP pultrusion profiles are highly resistant to the chemicals typically used in semiconductor manufacturing. The composite materials used in FRP profiles have excellent chemical resistance, making them ideal for withstanding the corrosive effects of various chemicals used in this industry.

- Q: Can FRP pultrusion profiles be used in the construction of wastewater treatment tanks?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can be used in the construction of wastewater treatment tanks. FRP materials are highly resistant to corrosion, making them suitable for harsh environments such as wastewater treatment facilities. Additionally, FRP pultrusion profiles offer high strength-to-weight ratio, durability, and low maintenance requirements, making them an ideal choice for constructing wastewater treatment tanks.

- Q: Can FRP pultrusion profiles be used in agricultural structures?

- Yes, FRP pultrusion profiles can certainly be used in agricultural structures. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various applications in the agricultural industry. These profiles can be used in structures like greenhouse frames, livestock enclosures, support beams, fencing, and other agricultural infrastructure.

- Q: Can FRP pultrusion profiles be used in wastewater treatment facilities?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in wastewater treatment facilities. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, which make them suitable for use in harsh environments like wastewater treatment facilities. In wastewater treatment facilities, there are various applications where FRP pultrusion profiles can be used. These include but are not limited to walkways, handrails, ladders, grating, and structural supports. The corrosion resistance of FRP makes it ideal for use in areas exposed to moisture and chemicals present in wastewater. Furthermore, FRP profiles are lightweight, which simplifies installation and reduces the load on supporting structures. The durability of FRP pultrusion profiles ensures long-term performance, even in aggressive environments. They have a high resistance to chemical attack, UV radiation, and bacterial growth, making them suitable for wastewater treatment applications. Additionally, FRP profiles can be designed to meet specific load requirements and can be easily fabricated to fit various shapes and sizes. Moreover, FRP pultrusion profiles offer excellent electrical insulation properties, which can be advantageous in wastewater treatment facilities where electrical safety is a concern. In summary, FRP pultrusion profiles can be effectively used in wastewater treatment facilities due to their corrosion resistance, durability, lightweight nature, and versatility in design and fabrication. These profiles can provide long-lasting solutions for various applications within these facilities, ensuring operational efficiency and minimizing maintenance requirements.

- Q: How do FRP pultrusion profiles handle torsion loads?

- FRP pultrusion profiles are known for their excellent mechanical properties and high strength-to-weight ratio, making them an ideal choice for handling torsion loads. When subjected to torsion, these profiles are designed to withstand twisting forces and maintain their structural integrity. The key to their ability to handle torsion loads lies in their construction. FRP pultrusion profiles are manufactured by pulling reinforcing fibers, such as fiberglass, through a resin bath and then through a heated die. This process aligns the fibers in the direction of the load, providing exceptional strength and stiffness. In the case of torsion loads, the aligned fibers in the profile's cross-section resist the twisting force by distributing it along the length of the profile. This distribution of force helps prevent localized stress concentrations, reducing the risk of deformation or failure. Additionally, the resin matrix surrounding the fibers acts as a binding agent, holding the fibers together and providing protection against environmental factors such as moisture, chemicals, and UV radiation. This ensures the long-term durability and stability of the profile under torsion loads. Furthermore, FRP pultrusion profiles can be designed with specific cross-sectional shapes and dimensions to enhance their torsional strength. By optimizing the geometric configuration, such as increasing the wall thickness or adding reinforcing ribs, the profiles can be further strengthened to meet the desired torsion load requirements. Overall, FRP pultrusion profiles excel in handling torsion loads due to their inherent properties, manufacturing process, and design flexibility. Their ability to resist twisting forces, coupled with their lightweight nature, makes them a reliable and cost-effective choice for various applications, including construction, infrastructure, aerospace, and automotive industries.

- Q: Can FRP pultrusion profiles be used in the construction of highway guardrails?

- Yes, FRP pultrusion profiles can be used in the construction of highway guardrails. FRP (Fiber Reinforced Polymer) pultrusion profiles offer excellent strength-to-weight ratio, corrosion resistance, and durability, making them a suitable choice for guardrails. They are lightweight, easy to install, and require minimal maintenance, making them cost-effective in the long run. Additionally, FRP profiles can be molded into various shapes and sizes to meet specific design requirements, ensuring the safety and effectiveness of the highway guardrails.

- Q: How do FRP pultrusion profiles perform in extreme cold temperatures?

- FRP pultrusion profiles generally perform very well in extreme cold temperatures. This is due to the inherent properties of the materials used in their construction. FRP (fiber-reinforced polymer) composites are known for their excellent thermal insulation properties, which help to maintain the structural integrity of the profiles even in extremely low temperatures. One key advantage of FRP pultrusion profiles in cold environments is their resistance to freezing and thawing cycles. Unlike some other materials, FRP does not absorb water, which means it does not expand or contract with temperature changes. This prevents cracking or damage that can occur when moisture freezes and expands within traditional materials such as metal or concrete. Furthermore, FRP pultrusion profiles have a low coefficient of thermal expansion, meaning they do not significantly expand or contract with temperature fluctuations. This stability allows them to maintain their shape and structural integrity in extreme cold, reducing the risk of deformation or failure. In addition to their thermal properties, FRP pultrusion profiles also exhibit high strength and durability, making them suitable for use in various applications such as construction, infrastructure, and transportation, even in harsh cold environments. They are resistant to corrosion, chemicals, and UV radiation, further enhancing their performance and longevity in extreme conditions. Overall, FRP pultrusion profiles are an excellent choice for applications requiring reliable performance in extreme cold temperatures. Their thermal insulation properties, resistance to freezing and thawing cycles, low coefficient of thermal expansion, and overall strength and durability make them well-suited for various industries and environments, ensuring their continued performance even in the harshest cold conditions.

- Q: Can FRP pultrusion profiles be used in the oil and gas industry?

- Yes, the oil and gas industry can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles offer numerous advantages that make them suitable for use in this sector. To begin with, FRP pultrusion profiles exhibit corrosion resistance. They remain unaffected by harsh conditions such as saltwater, chemicals, and extreme temperatures, thereby avoiding rusting, corrosion, or degradation. Consequently, they prove ideal for offshore platforms, pipelines, and other oil and gas facilities where corrosion poses a significant problem. Moreover, FRP pultrusion profiles possess a high strength-to-weight ratio. Despite being lightweight, they possess remarkable strength, enabling efficient installation, transportation, and handling. This aspect is especially advantageous in the oil and gas industry, where reducing weight is crucial for enhancing operational efficiency and decreasing costs. Additionally, FRP pultrusion profiles can be customized to meet specific requirements. They can be manufactured in various shapes, sizes, and configurations, making them adaptable for diverse applications within the oil and gas industry. Whether it be for structural supports, grating, handrails, or other components, FRP pultrusion profiles can be tailored to perfectly suit the distinct needs of each project. Furthermore, FRP pultrusion profiles offer exceptional electrical insulation properties. This attribute holds immense importance in the oil and gas industry, where electrical safety is of utmost priority. By providing insulation and preventing electrical conductivity, FRP profiles reduce the risk of accidents and ensure the safety of both personnel and equipment. In conclusion, FRP pultrusion profiles have demonstrated their reliability, durability, and cost-effectiveness across various applications within the oil and gas industry. Their resistance to corrosion, high strength-to-weight ratio, customization capabilities, and electrical insulation properties make them an appealing choice for this demanding sector.

- Q: Are FRP pultrusion profiles non-conductive?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are non-conductive. This is because they are made up of a combination of reinforced fibers, typically fiberglass, and a polymer resin matrix. The fiberglass fibers provide the strength and stiffness, while the polymer resin acts as a binder to hold the fibers together. One of the key advantages of FRP pultrusion profiles is their excellent electrical insulation properties. Unlike metals, which are conductive, FRP profiles do not conduct electricity. This makes them ideal for applications where electrical insulation is required. In addition to being non-conductive, FRP pultrusion profiles also offer other benefits such as corrosion resistance, high strength-to-weight ratio, and low maintenance requirements. These properties make them suitable for a wide range of applications, including electrical and telecom infrastructure, chemical processing plants, bridges, and building construction. It is important to note that the non-conductive nature of FRP pultrusion profiles does not mean they cannot be made conductive if required. Special additives or coatings can be incorporated during the manufacturing process to impart conductive properties if needed.

- Q: Can FRP pultrusion profiles be used in the construction of offshore platforms?

- Yes, FRP pultrusion profiles can be used in the construction of offshore platforms. FRP, or fiber-reinforced polymer, offers excellent corrosion resistance, high strength-to-weight ratio, and durability, making it suitable for the harsh marine environment. These profiles can be customized to meet the specific requirements of offshore platforms, providing structural support and stability while minimizing maintenance needs.

Send your message to us

FRP Pultrusion Profiles - Solid FRP Flooring Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords