FRP Pultrusion Profiles - GRP/FRP Plastic Pultruded Grating Fiberglass Floor Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 80000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

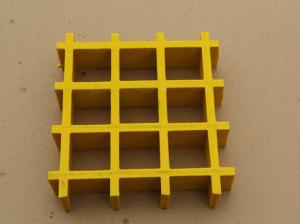

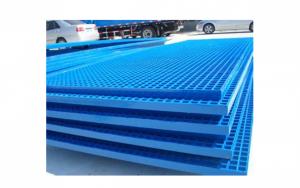

PRODUCT DESCRIPTION

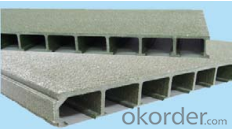

FRP flooring panel is a big size profile which is made by pultrusion technology and in holistic shape, it could form a continuours close plane by unique self-lock structure,which could be used as load structures in various corrosion environments and could replace wood plate, aluminum plate or steel plate etc.

The product could add natural color grit on the surface,which is safe for the anti-slippery,besides it could obtain the natural appearance and no fadding for a long time.

Deck of cooling tower, plate of scaffold, floor of chip manufacturing, deck of bridge, rooftop, slope of architectural overhaul, structural floor, floor of light railcar, baffle of equipment, roof of cover, trench cover, footpath, weather plank.

FEATURES

a. anti-corrosion, non-rusty

b. lightweight and high strength

c. anti-flammable

d. anti-fatigue

e. anti-slippery and safety

f. anti-ageing

g. easy to installation and maintenance

h. excellent electromagnetism property

SPECIFICATION

Item No. | Height(mm) | Mesh Size(mm) | Standard Panel Size | Open Area | Weight(kg/m2) |

1 | 15 | 38 × 38 | 1220 × 3660 | 72% | 6.00 |

2 | 15 | 20 × 20 | 1247×4047,1007×4047 | 42% | 9.00 |

3 | 25 | 38 ×38 | 997 × 3050 , 1220 × 3660 | 69% | 12.32 |

4 | 25 | 40 × 40 | 1007 × 3007, 1007 × 4007, | 67% | 12.20 |

5 | 25 | 25 × 100 | 1009 × 3007 ,1209 ×3657 | 67% | 13.87 |

6 | 30 | 38 × 38 | 1220 × 3660 , 997 × 3050 | 69% | 14.60 |

7 | 30 | 40 × 40 | 1007 × 3007 , 1007 × 4007 | 67% | 14.28 |

8 | 30 | 20 × 20 | 1000 × 4000,1247×4047 | 42% | 18.10 |

9 | 38 | 38 × 38 | 997 × 3050 , 1220 × 3660 | 68% | 19.71 |

10 | 38 | 25 × 152 | 1226 × 3665 (Bearing bars to run length direction) | 56% | 22.40 |

11 | 38 | 20 × 20 | 1007 × 4007,1247×4047 | 42% | 22.50 |

12 | 40 | 40 × 40 | 1007 × 3007 ,1007 × 4007, 1007 × 4047 ,1247 × 4047 | 67% | 19.87 |

13 | 40 | 20 × 20 | 1247 × 4047 | 42% | 23.70 |

14 | 50 | 50.7 × 50.7 | 1225× 3660 | 69% | 22.17 |

15 | 60 | 38 × 38 | 1220 × 3660 | 47% | 50.43 |

16 | P38 | 38 × 38 | 1230 × 3670 | 68% | 17.5 |

17 | P30 | 38 × 38 | 1220 × 3660 | 69% | 14.0 |

PICTURES

- Q: Can FRP pultrusion profiles be used in the automotive industry?

- Certainly, the automotive industry can certainly make use of FRP (Fiber Reinforced Plastic) pultrusion profiles. These profiles possess several advantages that render them appropriate for automotive purposes. To begin with, FRP pultrusion profiles are lightweight, a critical factor in the automotive industry as it contributes to better fuel efficiency and reduced vehicle weight. Vehicles that are lighter consume less energy and emit fewer pollutants, making them more eco-friendly. Moreover, FRP pultrusion profiles exhibit a remarkable strength-to-weight ratio, enabling them to provide high strength and stiffness while remaining lightweight. This characteristic makes them ideal for structural components in automobiles, such as chassis, body panels, and support structures. In addition, FRP pultrusion profiles display exceptional corrosion resistance, a considerable advantage in automotive applications. Vehicles are frequently exposed to harsh environmental conditions, including moisture, salt, and chemicals. The corrosion resistance of FRP ensures the durability and longevity of automotive components, even in challenging environments. Furthermore, FRP pultrusion profiles possess impressive impact resistance, a crucial aspect of automotive safety. They can effectively absorb and dissipate energy during impacts, reducing the risk of injury in the event of accidents. Moreover, FRP pultrusion profiles can be customized and engineered to meet specific design requirements, allowing for versatility in automotive applications. They can be tailored to possess specific mechanical properties, shapes, and sizes, making them suitable for various automotive components. Overall, the combination of lightweight construction, high strength, corrosion resistance, impact resistance, and customization options make FRP pultrusion profiles an excellent choice for the automotive industry. They offer numerous benefits, including improved fuel efficiency, enhanced safety, and extended component life, making them a viable alternative to traditional materials in automotive applications.

- Q: How do FRP pultrusion profiles perform in earthquake-prone areas?

- FRP (Fiber Reinforced Polymer) pultrusion profiles perform exceptionally well in earthquake-prone areas due to their inherent properties. The high strength-to-weight ratio of FRP materials provides excellent resilience against seismic forces. Additionally, FRP pultrusions have high flexural strength, which enables them to withstand bending and torsional loads during earthquakes. Moreover, FRP profiles are corrosion-resistant, making them ideal for long-term durability in areas prone to seismic activity. Overall, FRP pultrusion profiles offer a reliable and robust solution for structural applications in earthquake-prone regions.

- Q: Can FRP pultrusion profiles be used in the agricultural and farming industry?

- Yes, FRP pultrusion profiles can certainly be used in the agricultural and farming industry. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength, durability, and resistance to corrosion, making them ideal for outdoor and harsh environments such as those found in the agricultural and farming industry. These profiles can be used for various applications in agriculture and farming, including: 1. Fencing and enclosures: FRP pultrusion profiles can be used to create sturdy and long-lasting fences, gates, and enclosures for livestock and crop protection. The profiles are resistant to rot, rust, and insect damage, providing a reliable barrier for animals and crops. 2. Structural components: FRP pultrusion profiles can be used as structural components in agricultural buildings, sheds, and greenhouses. Their high strength-to-weight ratio allows for the construction of lightweight and durable structures that can withstand extreme weather conditions. 3. Irrigation systems: FRP pultrusion profiles can be used in the construction of irrigation systems, such as pipes, channels, and culverts. These profiles are non-corrosive and have a smooth interior surface, reducing friction and improving water flow efficiency. 4. Equipment support and framing: FRP pultrusion profiles can be used to provide support and framing for various agricultural equipment, such as conveyors, platforms, and machinery. Their high strength and stiffness make them suitable for heavy-duty applications. 5. Animal housing and equipment: FRP pultrusion profiles can be used to construct animal housing and equipment, such as pens, stalls, and feeding troughs. These profiles are resistant to chemicals, moisture, and UV radiation, ensuring a long lifespan and low maintenance requirements. In summary, FRP pultrusion profiles can be successfully utilized in the agricultural and farming industry due to their excellent mechanical properties, resistance to environmental factors, and versatility in various applications.

- Q: Can FRP pultrusion profiles be used in the construction of conveyor systems?

- FRP pultrusion profiles are highly effective in the construction of conveyor systems. They offer numerous advantages that make them suitable for this purpose. To begin with, these profiles are both lightweight and strong, making them ideal for constructing conveyor systems. Their high strength-to-weight ratio allows for easy installation and maintenance, reducing the overall weight of the system while maintaining structural integrity. This is particularly beneficial when designing and building long-span conveyor systems. Additionally, FRP pultrusion profiles are highly resistant to corrosion. Unlike traditional materials such as steel or aluminum, they do not rust or deteriorate when exposed to chemicals or moisture. This resistance makes them particularly suitable for conveyor systems that may be subjected to harsh environments or corrosive substances, such as those found in the mining or chemical industries. Another advantage of FRP pultrusion profiles is their excellent electrical insulation properties. They do not conduct electricity, which is essential in conveyor systems where electrical components are present. This property ensures a higher level of safety and reduces the risk of electrical hazards. Furthermore, these profiles can be easily customized to meet specific design requirements. They can be manufactured in various shapes and sizes, providing flexibility in conveyor system design. Additionally, they can incorporate features such as channels, slots, or reinforcements, which can be advantageous for mounting accessories or facilitating the movement of goods on the conveyor. Lastly, FRP pultrusion profiles are highly durable and have a long service life. They are resistant to UV degradation and do not require frequent maintenance or painting, resulting in reduced lifecycle costs compared to traditional materials. This durability makes them a cost-effective choice for constructing conveyor systems. In conclusion, FRP pultrusion profiles are an excellent option for constructing conveyor systems. Their lightweight nature, corrosion resistance, electrical insulation properties, customization options, and durability make them a reliable and efficient material for this application.

- Q: Can FRP pultrusion profiles be used in pedestrian bridges?

- FRP pultrusion profiles can indeed be utilized in pedestrian bridges. They possess several advantages that render them appropriate for bridge construction, including their exceptional strength-to-weight ratio, resistance to corrosion, and durability. These profiles are manufactured by pulling continuous fibers through a resin bath and subsequently through a heated die, yielding a material that is both robust and lightweight. The lightweight nature of FRP pultrusion profiles makes them an ideal choice for pedestrian bridges, as they can be easily transported and installed. Furthermore, their high strength enables them to withstand the load requirements imposed by pedestrian traffic. Moreover, these profiles exhibit exceptional resistance to corrosion, which is particularly crucial for bridges that are exposed to environmental elements such as rain, humidity, and saltwater. In addition, FRP pultrusion profiles are highly durable and necessitate minimal maintenance in comparison to traditional construction materials like steel or concrete. They are impervious to rust or rot, and their non-conductive properties guarantee their safety when employed in areas with electrical infrastructure. To summarize, FRP pultrusion profiles present a suitable option for pedestrian bridges due to their lightweight nature, high strength, resistance to corrosion, and durability. These profiles offer a cost-effective and long-lasting solution for bridge construction, ensuring the safety and convenience of pedestrians.

- Q: Are FRP pultrusion profiles resistant to fungal growth?

- Yes, FRP pultrusion profiles are highly resistant to fungal growth. The composite materials used in FRP pultrusion, such as fiberglass and resin, do not provide a suitable environment for fungi to grow. Additionally, the smooth surface of FRP profiles makes it difficult for fungi to attach and thrive. Hence, FRP pultrusion profiles are an excellent choice for applications where resistance to fungal growth is required.

- Q: Are FRP pultrusion profiles resistant to caustic soda?

- Yes, FRP pultrusion profiles are generally resistant to caustic soda. The corrosion-resistant properties of FRP make it suitable for use in environments that involve caustic soda or other aggressive chemicals. However, it is always recommended to evaluate the specific conditions and concentration of the caustic soda to ensure the compatibility of FRP profiles.

- Q: Can FRP pultrusion profiles be used in the construction of industrial flooring?

- Yes, FRP pultrusion profiles can be used in the construction of industrial flooring. These profiles are lightweight, durable, and corrosion-resistant, making them an ideal choice for industrial applications. They offer high strength-to-weight ratio, excellent load-bearing capacity, and resistance to chemicals, moisture, and extreme temperatures. Additionally, FRP pultrusions can be customized to meet specific design requirements, making them versatile for various industrial flooring applications.

- Q: Are FRP pultrusion profiles resistant to chemicals used in chemical plants?

- FRP pultrusion profiles exhibit a general resistance to a wide range of chemicals employed in chemical plants. Their exceptional chemical resistance properties make FRP materials appropriate for diverse industrial applications, including chemical plants. The pultruded FRP profiles are manufactured by saturating reinforcing fibers with a thermosetting resin, such as polyester, vinylester, or epoxy. The selection of these resins is based on their resistance to various chemicals and can be tailored to meet specific requirements. FRP pultrusion profiles have demonstrated their ability to withstand aggressive chemicals, including acids, bases, solvents, and corrosive gases. Most common chemicals found in chemical plants, such as sulfuric acid, hydrochloric acid, nitric acid, and sodium hydroxide, typically do not affect them. Nevertheless, it is important to consider that the resistance of FRP pultrusion profiles may vary depending on the specific resin system, as well as the concentration and temperature of the chemicals involved. To ensure the suitability of the chosen FRP profiles for the chemical environment in a chemical plant, it is always advisable to consult with the manufacturer or supplier.

- Q: Do FRP pultrusion profiles have any limitations or drawbacks?

- Yes, FRP pultrusion profiles do have some limitations and drawbacks. One limitation is their susceptibility to UV degradation, which can cause discoloration and reduced mechanical properties over time if not properly protected. Additionally, FRP pultrusion profiles have relatively low impact resistance compared to materials like steel or aluminum. They may also have limited fire resistance and can melt or burn under high temperatures. Finally, the manufacturing process for FRP pultrusion profiles can be time-consuming and expensive, making it less suitable for small-scale or customized applications.

Send your message to us

FRP Pultrusion Profiles - GRP/FRP Plastic Pultruded Grating Fiberglass Floor Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 80000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords