Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

1. Features for Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

Size: 20mm-150mm(Dia0.75''-Dia6'')

Hardness: HRC60-HRC65

Low Breakage Rate<0.5%

Impact Toughness>12J/cm2

Endurance Test>10000times

Good Wear Resistant

2. Chemical Composition for Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

Brand | Grade | C | Mn | Si | Cr | S | P |

CMAX-1 | 50Mn | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | 0.25max | 0.035max | 0.035max |

CMAX-2 | 60Mn | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | 0.25max | 0.035max | 0.035max |

CMAX-3 | 65Mn | 0.6-0.7 | 0.9-1.2 | 0.17-0.37 | 0.25max | 0.035max | 0.035max |

CMAX-4 | 75MnCr | 0.70-0.85 | 0.7-0.8 | 0.17-0.37 | 0.2-0.7 | 0.03max | 0.03max |

CMAX-5 | Rail IronⅠ | 0.5-0.65 | 0.60-1.0 | 0.15-0.37 | 0.25max | 0.04max | 0.04max |

CMAX-6 | Rail IronⅡ | 0.60-0.8 | 0.90-1.2 | 0.20-0.40 | 0.20-0.8 | 0.07max | 0.03max |

3. Weight and Microstructure for Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

Norminal Diameter | Diametrical Tolerance(mm) | Approx Weight of Single Ball(kg) | Average Number of One MT | Microstructure |

25mm/1'' | +1.5,-0.5 | 0.064 | 15625 | M+B+C (M-Martensite;B-Bainitic;C-Carbide) |

30mm/1.25'' | +1.5,-0.5 | 0.11 | 9090 | |

40mm/1.5'' | +2.0,-1.0 | 0.26 | 3846 | |

50mm/2'' | +2.0,-1.0 | 0.51 | 1961 | |

60mm/2.5'' | +3.0,-2.0 | 0.89 | 1124 | |

70mm/2.75'' | +3.0,-2.0 | 1.4 | 714 | |

80mm/3.25'' | +3.0,-2.0 | 2.1 | 476 | |

90mm/3.5'' | +3.0,-2.0 | 3 | 333 | |

100mm/4'' | +4.0,-3.0 | 4.1 | 244 | |

110mm/4.5'' | +4.0,-3.0 | 5.47 | 283 | |

120mm/4.75 | +4.0,-3.0 | 7.1 | 141 | |

130mm/5'' | +4.0,-3.0 | 9.02 | 111 |

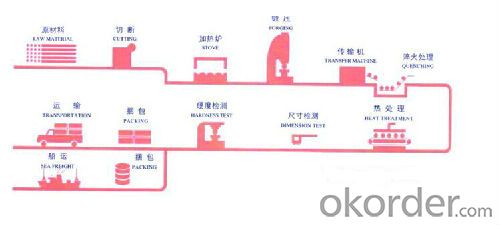

4. Production Process for Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

5. Packing Ways for Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

- Q: How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- Yantai five God casting is generally 53 yuan /kg, the appearance is quite beautiful

- Q: The casting defects of pores, trachoma how to repair?

- If the repair after the high temperature resistance, choose LT737 high temperature repair agent.

- Q: What are the requirements for casting steel castings?

- 2, the plane should be placed on the following.3, thin parts should be placed below.

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- Mainly because of the cooling shrinkage caused by internal stress caused. There is the change of temperature distribution in materials element imbalance, is typical of surface and internal, thin wall and thick wall, bottom and top.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: How can the casting be quenched and tempered?

- Another is the result of pre heat treatment (quenching or annealing) after quenching and tempering treatment, suitable for ZG35SiMNMo, ZG35CrMo and so on. Please tell the casting process is your product and material and then set tempered.: shutup:

- Q: What kind of flaw detector is better for casting parts?

- If you want to detect internal defects, you can use ultrasonic flaw detector, ray flaw detector can also, but the ray of the safety protection level is too high, not recommended priorityMacro Xu flaw detector answered, such as the magnetic particle inspection machine has the demand can contact us, Baidu "macro Xu flaw detection""

- Q: What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

- Q: How can the casting be free of trachoma?

- 3, the gate is not facing sand core, flush sand core, will cause trachoma.

1. Manufacturer Overview

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

Forged Steel Grinding Ball with Dia0.75’’-Dia6’’ & Hardness HRC60-HRC65 & ISO9001:2008

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords