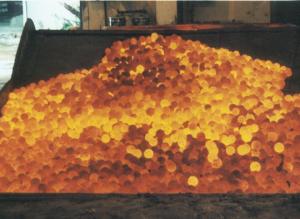

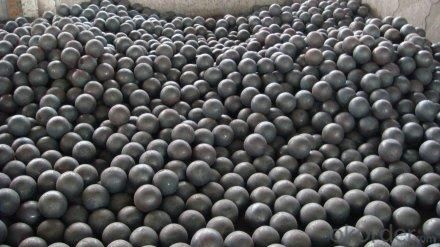

Precision High Chrome Casting Balls

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 TONS m.t.

- Supply Capability:

- 1000 Ton per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chrome Steel Ball

We are a professional manufacturer which produce media ball.Our steel ball exported to

Chemcial Elements of Chrome Steel Ball

Name | C | Mn | Si | Cr | S | P |

50MN | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

60MN | 0.57-.0.65 | 0.7-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65MN | 0.60-0.70 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.85 | 0.70-0.80 | 0.17-0.37 | 0.2-0.7 | ≤0.03 | ≤0.03 |

Specification and Hardness of Chrome Steel Ball

Name | Impact Test AK.J/cm2 | Endurance Test Times (5m) | Dia 25mm-60mm | Dia 70mm-100mm | ||

Surface | Core | Surface | Core | |||

50MN | ≥12 | ≥10000 | ≥56 | ≥50 | ≥55 | ≥50 |

60MN | ≥13 | ≥12000 | ≥58 | ≥52 | ≥58 | ≥50 |

65MN | ≥15 | ≥12000 | ≥62 | ≥54 | ≥58 | ≥52 |

B2 | ≥15 | ≥12000 | ≥62 | ≥55 | ≥58 | ≥52 |

Weigh of Chrome Steel Ball

Norminal Diameter | Diametrical Tolerance(mm) | Approx Weight of Single Ball(kg) | Average Number of One MT |

20mm/0.75'' | +1,-0.5 | 0.033 | 30303 |

25mm/1'' | +1,-0.5 | 0.064 | 15625 |

30mm/1.25'' | +2.0,-1.0 | 0.11 | 9090 |

40mm/1.5'' | +2.0,-1.0 | 0.261 | 3831 |

50mm/2'' | +2.0,-1.0 | 0.510 | 1961 |

60mm/2.5'' | +2.0,-1.0 | 0.883 | 1132 |

70mm/2.75'' | +3.0,-1.5 | 1.402 | 713 |

80mm/3.25'' | +3.0,-1.5 | 2.092 | 478 |

90mm/3.5'' | +3.0,-1.5 | 2.98 | 335 |

100mm/4'' | +3.0,-1.5 | 4.087 | 244 |

110mm/4.5'' | +3.0,-1.5 | 5.44 | 183 |

120mm/4.75 | +3.0,-1.5 | 7.062 | 141 |

Applied fields of Chrome Steel Ball

a).Mines

b).Cement plant

c).Chemical Industries

Chrome Steel Ball Packing

Steel drum: 800-1000kgs;

Container bag: 1000kgs.

- Q: The casting defects of pores, trachoma how to repair?

- Airhole above 2mm recommended LT101 casting defect repair agent. If repair quality requirements, high availability LT111 iron repair agent, LT112 steel repair agent, LT113 aluminum repair agent, LT114 copper repair agent.

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- 1, qualified enterprises will directly iron ore into molten iron, and then poured into the mold, such a good product performance. I work in the cast iron industry, which I can tell you for sure.2, this, like the Great Wall Motor Company has its own parts production department, as well as the corresponding mold center, so it will be their own casting. If the manufacturer does not have these departments, they can only place orders for others to do.

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: What method of casting does not rust? I think the sample is like oil

- Close to the solder, and slowly dissolve is hot melt double-sided adhesive, otherwise it is oily double-sided adhesive.

- Q: In theory, which is more expensive, forging parts or casting parts?

- The structure of the casting is relatively flexible in design, and the modeling is easy to realize.

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- Vacuum casting is the process of using ventilation molds. Molten metal flows into the mold by air pressure, and then removes air to form a vacuum. The casting process is mainly used for small parts or jewelry with exquisite detailsCompared with the traditional clay sand casting, heat hardening resin sand casting production with low surface roughness, high precision, good quality characteristics, dimensional accuracy of resin sand mold after hardening with good rigidity and high, and not easy to deform, so in the choice of process parameters, mechanical processing you can select a smaller margin, thereby reducing the consumption of metal solution and machining cost, which can improve the dimensional accuracy of castings.

- Q: What's the density of the cast iron? The density is thin and the density is thin

- There is a hot knot in the thick area, which easily causes microscopic shrinkage and makes the casting not dense. A riser may be added for shrinkage relief.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: How to cast iron and wrought iron collocation

- 3, if you have a file in the hand, can be used to file to see finish can also make a judgment from the file down the iron can also be seen, but this is beyond your request, it can be done in the factory. 4, if placed in the grinder grinding, see iron spark from a judge or iron wrought iron, but this is only to do in the factory. About it, may not be full, but through these methods, generally can distinguish between iron or wrought iron.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

1. Manufacturer Overview

| Location | Anhui, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 5 million |

| Main Markets | Mid East; Eastern Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 21% - 50% |

| No.of Employees in Trade Department | 31-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 40,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Precision High Chrome Casting Balls

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 TONS m.t.

- Supply Capability:

- 1000 Ton per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords