Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

1. Introduction of Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

Grinding Ball as a medium for grinding machine, is consumables. Its main application is grinding materials to the usage standard. It is widely used in metal mines, power station, cement plant, chemical industry, etc.

2. Specification of Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

Size: 15-150mm

Hardness: 55-65HRC

Breakage Rate<0.5%

Impact Toughness>12J/CM2

Endurance Test>20000times

3. Chemical Composition of Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

Material | C | Mn | Si | Cr | S | P | V |

45# | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

50Mn | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

60Mn | 0.57-0.65 | 0.7-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

65Mn | 0.60-0.70 | 0.9-1.2 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

B2 | 0.7-0.85 | 0.7-0.8 | 0.17-0.37 | 0.2-0.7 | ≤0.03 | ≤0.03 | |

75SiMn | 0.7-0.90 | 0.7-1.2 | 0.4-0.8 | ≤0.25 | ≤0.03 | ≤0.03 | |

Wear-resistant alloy | 0.5-0.65 | 0.4-1.0 | 1.4-1.8 | 0.9-1.2 | ≤0.03 | ≤0.03 | 0.1-0.2 |

4. Diametrical Tolerance and Weight of Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

Nominal diameter (mm) | Diametrical tolerance (mm) | Weight of Single of grinding ball in average | Number of piece of One ton grinding ball in average |

DIA 20 DIA 25 DIA 30 DIA 40 DIA 50 |

+2 -1 | 32 64 110 263 513 | 31250 15625 9090 3802 1949 |

DIA 60 DIA 70 DIA 80 DIA 90 DIA 100 |

+3 -2 | 888 1410 2104 2996 4110

| 1126 709 475 333 243 |

DIA 110 DIA 120 DIA 130 | +4 -2 | 5457 7102 9030 | 182 140 110 |

DIA 140 DIA 150 | +4 -3 | 11278 13871 | 88 72 |

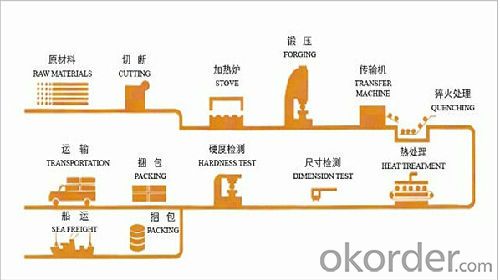

5. Production Process of Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

6. Testing Methods of Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

7. Packing Methods of Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

- Q: How to calculate the price of casting parts?

- Cost of raw materials + electricity (fuel) costs + workers' wages + managers' wages + transport costs + raw materials burned + accessories costs + equipment maintenance depreciation costs + management fees + tax. The most convenient, the raw material market price plus 2000 yuan, plus you want profits on the line.

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- Steel deformation control is one of the most common problems in the metal processing industry. Any process will occur. The casting is the largest deformation and the least fine. It is generally used to produce blank blanks

- Q: How to distinguish the forging parts and casting parts accurately

- Distinguish from performance:The processing performance of forged parts is higher than that of the same material. The forging parts are compact and have good mechanical properties, but the casting parts may have sand holes, holes, shrinkage holes and other defects, and their mechanical properties are inferior to those of forgings. At the same time, forging processing can ensure the continuity of the metal fibrous tissue, fibrous tissue to forging and forging shape consistency, metal streamline integrity, can ensure the parts with mechanical properties and long service life good.

- Q: Why do casting parts have air holes?

- There are many reasons for casting porosity, mainly due to:1. smelting process is unreasonable, metal liquid absorbs more gas;2. the gas in the mold invades the metal liquid;3. from the mold is more water brush, core dry;4. the casting has poor ventilation;5. ladle tools are not dry.Wait。

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizingGenerally 0.06 mm or more

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- According to the industry standards, within the scope of the standard requirements to determine whether the product is qualified

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Die die must charge, wood cheap, expensive aluminum mold

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- If is casting, internal shell mold may be not completely dry, strength is not enough, resulting in shell mold collapse into molten steel.It is also possible that the refractory is not refractory enough.

- Q: Can the casting part be phosphating with the phosphating solution of the pickling board?

- If it is Phosphating for painting, it is not necessary, because the surface of the casting is rough and can be firmly bonded with the paint film.

- Q: What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

1. Manufacturer Overview

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords