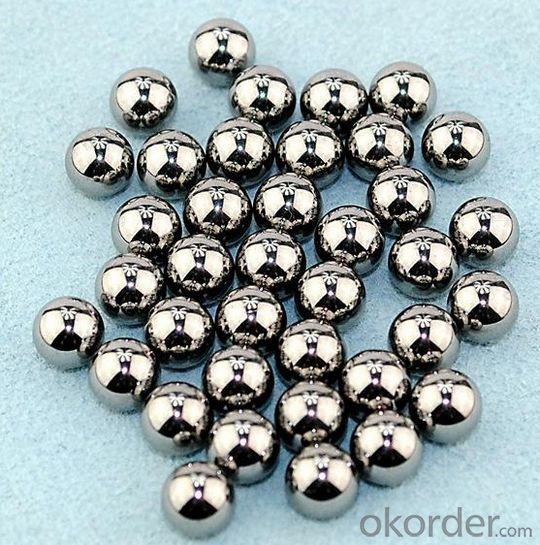

STAINLESS BALL WITH BEST QUALITY AND LOWEST PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

G100 6mm SS304 stainless steel ball for bearings(SGS approved) )

304 Stainless Steel Balls

Applied Area304 stainless steel ball can be used in iatrical instrument, chemical industry, aviation. Plastic hardware: scent bottle, sprayer, valve, nail polish, switch, washing machine, fridge, air condition, medicinal materials, automotive fittings, bearing, nursing

bottle and so on.

Speciality representative of Austenitic stainless steel. it is nonmagnetic, but magnetic after rolling, and the magnetism can be taken out, HRC≤26.It has good antirust and anticorrosive capability.

316 Stainless Steel Balls

Applied Are316 stainless steel ball is used in many special industry as iatrical instrument, chemical industry, aviation, scent bottle, sprayer, valve, nail polish, mobile phone fittings.

Speciality Austenitic stainless steels, It is the best steel ball in the steel ball area,HRC≤26,its Capability is better than 304 stainless steel ball.

420 Stainless Steel Balls

Applied Area420 stainless steel ball is used in the industry of high precision and antirust: motorcycle fittings, chain wheel,

stainless steel bearings, plastic bearings, craftwork, valve, petroleum and so on.

Speciality It is also called stainless iron, it is magnetic and has good antirust capability. The HRC is 50-55

Product Name | stainless steel ball |

Service | Your inquiry will be replied within 12 hours. |

Brand | HT |

Material | AISI 304, AISI 316, AISI 316L, AISI 420, AISI440, AISI440C and etc. |

Size | 0.7mm-25.4mm |

Feature | High polished, high precision, easy storage. |

Antirust Way | Provide dry packaging & slushing oil packaging. |

Grade | G10-G1000 |

Hardness | HRC 58-62 (If you have special requirements, please tell us.) |

Sample | Free |

Stock | There are emergency stocks for regular sizes. |

Packing Method | Standard Seaworthy Export Packing or Customized Packing |

- Q: How do casting parts remove stress?

- Annealing treatment, according to different casting annealing treatment, eliminate thermal stress, if need to restore hardness or increase hardness, and then quenching treatment

- Q: What are the effects of stiffeners on castings, or on welded parts (for 2 tons or less), casting or weldments on stiffeners?

- Please consider the following points:1, batch: if the product batch is very large, casting will certainly have advantages, cost sharing will be very low. If less, it is recommended to use weldments.2. Reinforcement structure: if the structure is relatively simple, it is recommended to use welded parts, complex, preferably casting.

- Q: Is the cast steel a casting part?

- Cast steel is divided according to material, as well as cast iron parts, cast aluminum parts and so onCasting parts are divided according to the method, as well as forging partsCast steel parts must be casting parts

- Q: What should I pay attention to when designing a casting structure?

- The basic structure of unit 3 in the design of metal casting casting and its parameters are selected, usually should also pay attention to: (1) because of the metal type heat quickly, so the metal type casting minimum wall thickness should be bigger than the sand casting casting casting; (2) the inner wall of the internal ribs and the thickness of a should be connected the outer wall thickness of 0.6 to 0.7, or as the inner wall (rib) cold slowly, cracks in the wall at the junction in the casting shrinkage; (3) to prevent generating white grey cast iron, in addition to taking measures in the process, must make the wall thickness is not too thin (some information that cast fillet at the corner of the wall thickness of 15mm or more, with metal casting casting must be in the corner, for Aluminum Alloy, metal casting magnesium alloy castings shall not be less than 3 ~ 4m; (4) because of the metal type and the core that, for To facilitate the extraction of castings and casting out type, slope casting should be suitably large than sand casting metal casting, the general should be 30% ~ 50%, it should be pointed out that in addition to the height of the slope of casting size and alloy type, wall, is also related to the casting surface position, where the cooling and contraction of the metal type the surface of casting surface can be designed from the tendency of small inclination, while casting shrinkage tend to be pressed on the surface of metal casting type should be given greater inclination.

- Q: For example, casting parts contain many holes, inclusions and other defects, the size and the number of holes exceed which limit is not qualified

- For example, the castings shall be in accordance with the requirements of the second types of castings in the technical requirements for aluminum alloy castings of GB/T9438-1999;

- Q: What are the causes of pitting on the surface of a precision casting?

- The quality of the shell surface is out of order. Or shot blasting out of question.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- If is casting, internal shell mold may be not completely dry, strength is not enough, resulting in shell mold collapse into molten steel.It is also possible that the refractory is not refractory enough.

- Q: Can the casting part be phosphating with the phosphating solution of the pickling board?

- Like stainless steel casting, duplex stainless steel casting is phosphating, ductile iron gray iron is not required

- Q: Is 316 casting better than 304 casting?

- The degree of difficulty in the process of casting depends mainly on the structure, precision requirements, and hardness of the casting. It is comprehensive. There is no simple comparison of the material to determine the degree of difficulty in processing

Send your message to us

STAINLESS BALL WITH BEST QUALITY AND LOWEST PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords