Forged Steel Grinding Ball with High Hardness & Good Wear Resistance & No Breakage(ISO9001:2008)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forged Steel Grinding Ball with High Hardness & Good Wear Resistance & No Breakage(ISO9001:2008)

1. Chemical Composition of Forged Steel Grinding Ball with High Hardness & Good Wear Resistance & No Breakage(ISO9001:2008)

Catalog | New Type Of High Efficiency Alloy Forging Steel Balls | High Hardness Wear-resistant Forging Steel Balls |

Size | DIA20-150mm | DIA20-150mm |

Hardness | HRC50-HRC60 | HRC58-HRC65 |

Chemical Elements | C:0.50-0.65 Si:0.15-0.37 Mn:0.6-1.2 S:≤0.04 P:≤0.04 Cr:≤0.25 | C:0.57-0.8 Si:0.2-0.4 Mn:0.8-1.2 S:≤0.04 P:≤0.04 Cr:≤0.25 |

2. Weight of Forged Steel Grinding Ball with High Hardness & Good Wear Resistance & No Breakage(ISO9001:2008)

Norminal Diameter | Diametrical Tolerance(mm) | Approx Weight of Single Ball(kg) | Average Number of One MT |

20mm/0.75'' | +1,-0.5 | 0.033 | 30303 |

25mm/1'' | +1,-0.5 | 0.064 | 15625 |

30mm/1.25'' | +2.0,-1.0 | 0.11 | 9090 |

40mm/1.5'' | +2.0,-1.0 | 0.261 | 3831 |

50mm/2'' | +2.0,-1.0 | 0.510 | 1961 |

60mm/2.5'' | +2.0,-1.0 | 0.883 | 1132 |

70mm/2.75'' | +3.0,-1.5 | 1.402 | 713 |

80mm/3.25'' | +3.0,-1.5 | 2.092 | 478 |

90mm/3.5'' | +3.0,-1.5 | 2.98 | 335 |

100mm/4'' | +3.0,-1.5 | 4.087 | 244 |

110mm/4.5'' | +3.0,-1.5 | 5.44 | 183 |

120mm/4.75 | +3.0,-1.5 | 7.062 | 141 |

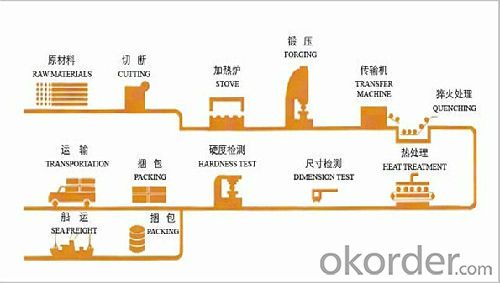

3. Production Process of Forged Steel Grinding Ball with High Hardness & Good Wear Resistance & No Breakage(ISO9001:2008)

4. Testing Methods of Forged Steel Grinding Ball with High Hardness & Good Wear Resistance & No Breakage(ISO9001:2008)

5. Packing Terms of Forged Steel Grinding Ball with High Hardness & Good Wear Resistance & No Breakage(ISO9001:2008)

Container Bags: net weight 1000kgs per bag, gross weight 1002kgs

Drums: Dia20-Dia80mm, 900kgs/Drum, gross weight: 915kgs

Dia90-Dia150mm, 850kgs/Drum, gross weight: 865kgs

- Q: What are the factors affecting the machining process of the casting material and structure?

- Medium carbon steel begins, and the casting can not be punched and tapped directlyStainless steel, ordinary grade (Fe based alloy element content, less) can not do heat treatment. But processing small holes or tapping to heat treatment (solution. In practice, the annealing treatment can also be). There are a lot of stainless steel matrix is not to say, for example, nickel, cobalt and tungsten. And so on.

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: The cause of fracture and why there is no toughness

- This question is too broad, see what the casting casting Oh in order to reduce the wayward cast steel, ductile iron, gray iron and white iron, you can choose the material according to their own requirements.

- Q: What should I pay attention to when designing a casting structure?

- (2) in the prevention of metal mold casting misrun and cold partition should pay attention to the following problems: the structure of A casting thickness should be appropriate not too thin, especially when casting size when not too thin; the B should avoid a big level, because it makes the liquid metal in the casting. Rise slowly, and the air contact surface, easy oxidation, and because the metal type liquid metal heat quickly, quickly lose liquidity, easy to cause misrun and cold lap, slag and other defects; C casting shape should be streamlined to avoid sharp corners and has sharp change connection structure in order to facilitate the flow of liquid metal. 2 in the design of metal castings in a complex shape, if the production process is very difficult, should not affect the casting conditions, try to make the casting has simple shape, strong structure change, removed from metallic die for.

- Q: How to cast iron and wrought iron collocation

- 2, listen: Pig beating sound boring, wrought iron beating sound loud.

- Q: Why do casting parts have air holes?

- There are many reasons for casting porosity, mainly due to:1. smelting process is unreasonable, metal liquid absorbs more gas;2. the gas in the mold invades the metal liquid;3. from the mold is more water brush, core dry;4. the casting has poor ventilation;5. ladle tools are not dry.Wait。

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- According to the industry standards, within the scope of the standard requirements to determine whether the product is qualified

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- Valve sand core mold drying is not in place, excessive water content

- Q: What's the cause of the choking of the casting?,

- Causes of choking fire:1., casting material in the pouring of gas;

- Q: Shandong foundry, casting small pieces of precision casting

- Dongying Huayang precision casting factory, the smallest to do 2G pieces.

1. Manufacturer Overview

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

Forged Steel Grinding Ball with High Hardness & Good Wear Resistance & No Breakage(ISO9001:2008)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords