Dia20mm-Dia150mm High & Low Chrome Cast Grinding Media Ball Used for Cement Plant

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Dia20mm-Dia150mm High & Low Chrome Cast Grinding Media Ball Used for Cement Plant

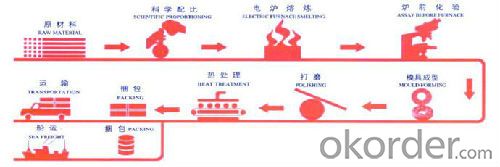

1. Production Process for Dia20mm-Dia150mm High & Low Chrome Cast Grinding Media Ball Used for Cement Plant

2. Chemical Composition for Dia20mm-Dia150mm High & Low Chrome Cast Grinding Media Ball Used for Cement Plant

Items | Brand | Chemical elements composition(%) | ||||||||

C | Si | Mn | Cr | Mo | Cu | Ni | P | S | ||

High chrome casting grinding ball | CMAX-7 | 2.0-2.8 | ≤1.0 | 0.5-1.5 | 22-28 | 0-3.0 | 0-2.0 | 0-1.5 | ≤0.10 | ≤0.10 |

High chrome casting grinding ball | CMAX-8 | 2.0-3.0 | ≤1.0 | 0.5-1.5 | 18-22 | 0-2.5 | 0-1.2 | 0-1.5 | ≤0.10 | ≤0.10 |

High chrome casting grinding ball | CMAX-9 | 2.0-3.0 | ≤1.0 | 0.5-1.5 | 14-17 | 0-3.0 | 0-1.0 | 0-1.5 | ≤0.10 | ≤0.10 |

High chrome casting grinding ball | CMAX-10 | 2.0-3.0 | ≤1.0 | 0.5-1.5 | 11~14 | 0-1.0 | 0-2.0 | 0-1.5 | ≤0.10 | ≤0.10 |

3. Mechanical Property for Dia20mm-Dia150mm High & Low Chrome Cast Grinding Media Ball Used for Cement Plant

Item | SIZES | ||||||||||||

φ20 | φ25 | φ30 | φ40 | φ50 | φ60 | φ70 | φ80 | φ90 | φ100 | φ110 | φ120 | φ130 | |

Tolerence | +1.0 | +2.0 | +3.0 | +3.5 | |||||||||

-1.0 | -1.0 | -1.0 | -1.5 | ||||||||||

Difference between max diam and min diam | ≤1.0 | ≤2.0 | ≤3.0 | ≤4.0 | |||||||||

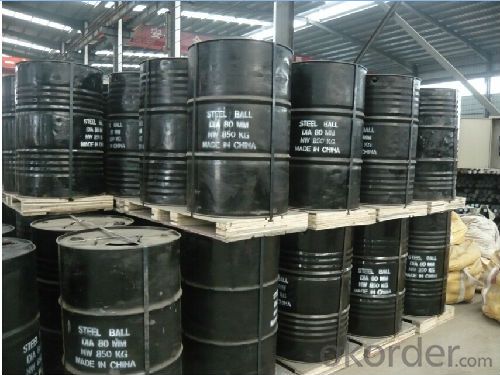

4. Packing Ways for Dia20mm-Dia150mm High & Low Chrome Cast Grinding Media Ball Used for Cement Plant

- Q: What are the casting parts used to test shrinkage holes?

- 2. x ray. This method can do nondestructive testing, but the cost is higher. Generally, high castings are required.

- Q: Why does the surface of stainless steel casting mirror mirror ripple?

- The surface can be improved by a little more than Xiasha

- Q: Why do cheap cars like stamping parts instead of casting parts?

- We usually say that the stamping is usually refers to the cold stamping parts, for example, a piece of iron, wants to turn it into a fast food dish, it must design a set of mold, mold is working face plate shape, the pressure plate mold, it becomes you want the dishes, this is the cold stamping die stamping is the direct use of metal materials.Automobile stamping parts are mainly classified according to process, and can be divided into two major parts: separation process and forming process.

- Q: What's the density of the cast iron? The density is thin and the density is thin

- Uneven casting density is caused by uneven shrinkage of the casting during solidification.

- Q: What should I pay attention to when designing a casting structure?

- 1 of the casting in metal mold cooling was faster than sand, metal type and let, thus casting in metal mold casting, casting stress generated in the ratio of sand casting to crack tendency is also large, but also prone to misrun and cold lap, white (for casting casting). Defect. Usually: (1) in the prevention of metal casting casting crack aspect should pay attention to the following problems: the structure of A in wall thickness, wall transition and connection to the ease, corner fillet appropriate requirements such as should be more strict than sand casting; B should be connected vertically connected with the wall to tilt C; for the weak parts of the structure should be set to strengthen ribs, bosses, to prevent casting; D should minimize the obstacle free shrinkage of the boss, casting rib, flange and other prominent part; E in the casting arrangement of ribs, but also should consider its influence on the casting shrinkage.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- Cracks are considered serious levels of defects and should be repaired

- Q: Why should pig iron be used in casting?

- Cast iron is generally called pig iron, but casting is not merely iron casting.For example, injection molding, die casting, and so on, in fact, cast iron, cast steel, cast aluminum, plastic and so on, can be used in the form of casting processing molding

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Even distribution is a good thing. Generally, the machining allowance of the casting is uneven.If the processing depends on how your processing techniques have been arranged.In the NC milling plane contour machining, when the rough margin is large, how to deal with.1. Return to the foundry, too large margin improvement.2. Then you can spend more time on it.

1. Manufacturer Overview

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

Dia20mm-Dia150mm High & Low Chrome Cast Grinding Media Ball Used for Cement Plant

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords