Forged SAE 8620 Alloy Steel Round Bar Special Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

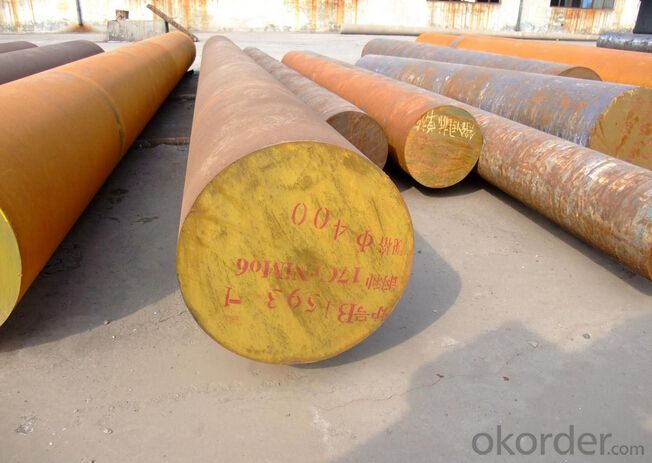

Forged SAE 8620 Alloy Steel Round Bar Special Steel

Description:

8620 is a low nickel - chromium - molybdenum medium hardenability, case hardening (carburizing) steel, generally supplied in the as rolled condition with a maximum brinell hardness of 280 (Rc30).

Characterised by good core strength and toughness in small to medium sections with case hardness up to Rc62 when carburized, hardened and tempered.

8620 can also be used (uncarburised) as a high tensile steel, which when suitably hardened and tempered can be utilized for various applications requiring good tensile strength and reasonable toughness.

Pre hardened and tempered (uncarburized) 8620 can be further surface hardened by nitriding but will not respond satisfactorily to flame or induction hardening due to its low carbon content.

8620 (carburized) is used extensively by all industry sectors for light to medium stressed components and shafts requiring high surface wear resistance with reasonable core strength and impact properties.

APPLICATIONS:

AISI 8620 is a common, carburizing alloy steel used for a variety of medium-strength applications including gears, camshafts, fasteners, and chains/chain pins. Flexibility in hardening treatments allow optimization of case/core properties. Typical uses are: Arbors, Bearings, Bushings, Cam Shafts, Differential Pinions, Guide Pins, King Pins, Pistons Pins, Splined Shafts, Ratchets, Sleeves etc..

Related Specifications

Australia AS 1444-1996-8620/8620H

Germany W.Nr 1.6523 DIN 21NiCrMo2

Great Britain BS970: PART 3: 1991 805 M20

BS970: 1955 - EN362

Japan JISG 4052 SNCM 220H

JIS SNCM 21 , JIS SNCM 21 H

U.S.A. SAE 8620 AISI 8620

ASTM A29/A29M 1991 8620

UNS G86200

AMS 6274 , AMS 6274G , AMS 6276 , AMS 6276C , AMS 6277 , AMS 6277A ,

ASTM A322 , ASTM A331 , ASTM A505 , ASTM A513 ,

MIL SPEC MIL-S-16974 ,

SAE J404 , SAE J770 ,

UNS G86200

France: AFNOR 20 NCD 2 , AFNOR 22 NCD 2

Italy: UNI 20 NiCrMo 2

Chemical Composition(%):

Carbon 0.17-0.23

Silicon 0.10-0.40

Manganese 0.60-0.95

Nickel 0.35-0.75

Chromium 0.35-0.75

Molybdenum 0.15-0.25

Phosphorous 0.04 max

Sulphur 0.04 max

Process: EAF+LF+VOD+Rolled+Heat Treatment(optional)

SURFACE FINISHES:

Black, Peeled (K12), Cold Drawn, Turned & Polished (H10, H11), Precision Ground (H9, H8)

Test: Ultrasonic test according to SEP 1921-84 3C/c

Forging

Heat to 1150 oC and hold until temperature is uniform throughout the section. Soaking time at forging temperature should be as short as possible to avoid heavy scaling and excessive grain growth. This will vary depending on furnace conditions but 15 minutes per 25 mm of section may be used as a guide.Do not forge below 850 oC.

Following completion of forging operation, work piece should be cooled as slowly as possible in sand or dry lime etc.

Note: Case hardening steels due to their low carbon content are less susceptible to cracking than medium or high carbon steels, and may therefore be heated and cooled more rapidly.

Machining

8620 in the as rolled as supplied condition, has very good machinability and all operations such as turning, drilling, milling and tapping etc. can be carried out satisfactorily as per machine manufacturers recommendations for suitable tool type - feeds and speeds.

Welding

8620 is readily weldable in the as rolled as supplied condition. Following welding, the work piece immediately upon cooling to hand warm should be stress relieved at 630 oC - 650 oC if possible.

N.B. Welding in the carburized and heat treated condition is not recommended.

Welding Procedure

Welding of 8620 should always be carried out using low hydrogen electrodes - please consult your welding consumables supplier.

Certificate of Quality: issued in English, in addition the normal terms, production process, the mechanical property (yield strength, tensile strength, elongation and hardness), forged ratio, UT test result, Grain size, heat treatment methods and the sample of is shown on the Certificate of Quality.

Marking: Heat No. will be cold stamped and Steel grade, diameter (mm), length (mm), and the manufacturer LOGO and weight (kg) is painted

Product Show:

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

4, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

WE provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How is silicon steel used in electrical transformers?

- Silicon steel is used in electrical transformers due to its unique magnetic properties. It has a high electrical resistance, low coercivity, and high magnetic permeability, making it an ideal material for the cores of transformers. The silicon content in the steel reduces the eddy current losses, enhancing the efficiency of the transformer. Additionally, the laminated structure of silicon steel helps to minimize the formation of eddy currents, further improving the performance and reducing energy losses in transformers.

- Q: What are the benefits of using special steel in the energy sector?

- The benefits of using special steel in the energy sector are numerous. Firstly, special steel offers exceptional strength, durability, and resistance to corrosion, making it ideal for withstanding the harsh conditions experienced in energy production and transmission. This allows for longer service life and reduced maintenance costs. Additionally, special steel possesses excellent heat resistance, enabling it to withstand high temperatures and pressure, making it suitable for use in power generation equipment such as turbines and boilers. Furthermore, special steel is highly versatile and can be customized to meet specific requirements, facilitating the design and construction of complex structures and components in the energy sector. Ultimately, the use of special steel enhances the reliability and efficiency of energy systems, contributing to overall sustainability and cost-effectiveness.

- Q: What are the advantages of using special steel in the renewable energy sector?

- Special steel offers several advantages when used in the renewable energy sector. Firstly, it provides enhanced strength and durability, allowing for the construction of robust and reliable components such as wind turbine towers and solar panel frames. This ensures prolonged operational life and increased resistance to harsh environmental conditions. Additionally, special steel exhibits excellent corrosion resistance, making it suitable for offshore wind farms and solar installations in coastal areas. Moreover, this type of steel can withstand extreme temperatures, enabling its use in concentrated solar power plants and geothermal energy systems. Overall, the use of special steel in the renewable energy sector enhances performance, extends lifespan, and improves the efficiency of renewable energy infrastructure.

- Q: What are the future trends in special steel manufacturing?

- Advancements in technology, sustainability, and the development of new alloys are expected to shape the future of special steel manufacturing. Technology will play a significant role, with automation and robotics being integrated into the production process. This integration will lead to improved efficiency, precision, and reduced labor costs. Quality control will also be enhanced, allowing for the production of more complex and customized steel products. Sustainability will be a key focus in the industry, driven by the growing environmental consciousness. Companies will seek to reduce their carbon footprint by adopting cleaner production methods, such as utilizing renewable energy sources and implementing recycling programs to minimize waste. Additionally, there will be a shift towards developing greener alloys with reduced environmental impact. The development of new alloys will be crucial in meeting the evolving needs of various industries. Material science advancements will enable special steel manufacturers to create alloys with enhanced properties, including increased strength, durability, corrosion resistance, and heat resistance. These new alloys will cater to the increasing demand for high-performance materials in sectors like aerospace, automotive, energy, and construction. Furthermore, the future of special steel manufacturing will be influenced by the rising demand for lightweight materials. Industries striving for improved fuel efficiency and reduced emissions will require special steel alloys that offer high strength-to-weight ratios. This will drive research and development efforts towards creating lighter yet stronger steel products. In conclusion, the future of special steel manufacturing will be shaped by advancements in technology, sustainability, and the development of new alloys. These trends will drive increased automation, cleaner production methods, and the creation of innovative alloys to meet the changing needs of various sectors.

- Q: How does special steel contribute to the creep resistance of products?

- Special steel contributes to the creep resistance of products through its unique properties and composition. Creep is the gradual deformation of a material under constant stress over time, and it is a critical concern in industries that require high temperatures and prolonged usage. Special steel, also known as high-temperature steel or heat-resistant steel, is specifically designed to withstand these extreme conditions and minimize creep. One of the key factors contributing to the creep resistance of special steel is its high melting point. Special steel is typically alloyed with elements such as chromium, nickel, molybdenum, and vanadium, which significantly increase its melting point compared to ordinary steel. This enhanced heat resistance allows special steel to maintain its structural integrity and resist deformation even at elevated temperatures. Moreover, the unique microstructure of special steel plays a crucial role in its creep resistance. Special steel is engineered to have a fine-grained structure, which improves its strength and prevents the movement of dislocations within the material. Dislocations are defects in the atomic arrangement of a material that can lead to creep deformation. By minimizing the movement of dislocations, special steel exhibits higher resistance to creep and maintains its shape and dimensional stability over extended periods. In addition to its microstructure, special steel often has a higher content of certain alloying elements. For instance, the addition of elements like molybdenum and vanadium enhances the creep strength of special steel by forming stable carbides within the material. These carbides act as barriers to dislocation movement, further impeding creep deformation and improving the overall creep resistance of the product. Furthermore, special steel is often subjected to advanced heat treatment processes, such as quenching and tempering, to optimize its mechanical properties and enhance its creep resistance. These heat treatments help to refine the microstructure, improve the distribution of alloying elements, and increase the hardness and strength of the material, all of which contribute to better resistance against creep. Overall, special steel's ability to withstand high temperatures, its unique microstructure, and its alloying elements and heat treatment processes combine to provide exceptional creep resistance. This makes special steel an ideal choice for various applications that require durability and longevity under extreme thermal conditions, such as gas turbines, nuclear reactors, high-temperature boilers, and aerospace components.

- Q: Can special steel be used in the railway industry?

- Yes, special steel can be and is commonly used in the railway industry. Special steel alloys such as manganese steel, stainless steel, and wear-resistant steel are often utilized in the manufacturing of railway tracks, wheels, axles, and other components. These special steel materials offer enhanced strength, durability, and resistance to corrosion and wear, making them ideal for withstanding the heavy loads, frequent use, and harsh environmental conditions experienced in the railway industry.

- Q: What are the main characteristics of heat-resistant steel?

- Heat-resistant steel, known as high-temperature steel as well, is an alloy with specific properties that enable it to endure extreme temperatures without sacrificing its mechanical strength and integrity. The primary features of heat-resistant steel are as follows: 1. Thermal fatigue resistance: Heat-resistant steel is designed to endure cyclic heating and cooling without developing cracks or fractures. This characteristic allows it to maintain its structural integrity, even in environments with rapid temperature fluctuations. 2. Exceptional creep resistance: Creep refers to the gradual deformation that occurs in a material when exposed to high temperatures over an extended period. Heat-resistant steel exhibits exceptional resistance to creep, ensuring that it retains its shape and strength even under prolonged heat exposure. 3. Preservation of mechanical properties at elevated temperatures: Unlike regular steel, which experiences a significant reduction in strength and hardness at high temperatures, heat-resistant steel retains its mechanical properties even under extreme conditions. This property makes it suitable for applications in industries such as aerospace, power generation, and oil and gas. 4. Resistance to oxidation and corrosion: Heat-resistant steel possesses a high resistance to oxidation and corrosion at elevated temperatures. It forms a protective oxide layer on its surface, preventing the underlying material from being attacked by oxygen or other corrosive elements. This property enhances the longevity and reliability of components made from heat-resistant steel. 5. Excellent thermal conductivity: Heat-resistant steel exhibits outstanding thermal conductivity, allowing it to efficiently transfer heat away from its surface. This feature proves particularly beneficial in applications where heat dissipation is crucial, such as in heat exchangers and furnace components. 6. Minimal thermal expansion: Heat-resistant steel has a relatively low coefficient of thermal expansion, meaning it expands and contracts minimally when subjected to temperature changes. This characteristic ensures dimensional stability and reduces the risk of warping or distortion under thermal stress. In summary, the main characteristics of heat-resistant steel make it an ideal material for applications that involve exposure to high temperatures, such as furnace components, exhaust systems, gas turbines, and heat exchangers. Its ability to endure extreme heat while maintaining its structural integrity and mechanical properties make it a critical material in industries where temperature resistance is of utmost importance.

- Q: Can special steel be used in the production of valves and fittings?

- Yes, special steel can be used in the production of valves and fittings. Special steel, such as stainless steel or alloy steel, offers excellent corrosion resistance, high temperature resistance, and durability, making it suitable for applications in various industries including oil and gas, chemical, and petrochemical.

- Q: How does special steel perform in terms of wear resistance in abrasive environments?

- Special steel is known for its exceptional wear resistance in abrasive environments. The unique composition and heat treatment processes used in the production of special steel result in a higher hardness level compared to standard steels. This increased hardness makes special steel highly resistant to wear caused by abrasive particles or surfaces. In abrasive environments where friction and contact with hard materials are prevalent, special steel exhibits excellent performance. It can withstand the erosive effects of abrasive particles, such as sand, rocks, or metal fragments, without significant wear or damage. This durability makes special steel an ideal choice for various applications, including mining equipment, cutting tools, industrial machinery, and automotive components. Moreover, the wear resistance of special steel is not only limited to its surface but also extends throughout its structure. This means that even if the surface of the steel is scratched or abraded, the underlying material remains highly resistant to wear. This characteristic ensures a prolonged lifespan of components made from special steel, reducing maintenance costs and downtime. Furthermore, special steel can maintain its wear resistance even under high temperatures. This property is particularly advantageous in abrasive environments where friction-induced heat can accelerate wear. The ability of special steel to retain its hardness and wear resistance at elevated temperatures ensures its effectiveness in demanding applications like high-speed machining or hot forging. Overall, special steel outperforms standard steels in terms of wear resistance in abrasive environments. Its superior hardness, structural integrity, and temperature resistance make it an excellent choice for applications where durability and longevity are essential.

- Q: What are the different methods for nitriding special steel?

- There are several methods for nitriding special steel, including gas nitriding, salt bath nitriding, plasma nitriding, and ion nitriding.

Send your message to us

Forged SAE 8620 Alloy Steel Round Bar Special Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords