Aluminum Decorative Metal Sheets - Food Grade Coating Stucco Embossed Aluminum Freezer Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Food Grade Coating Stucco Embossed Aluminum Freezer Sheet Description:

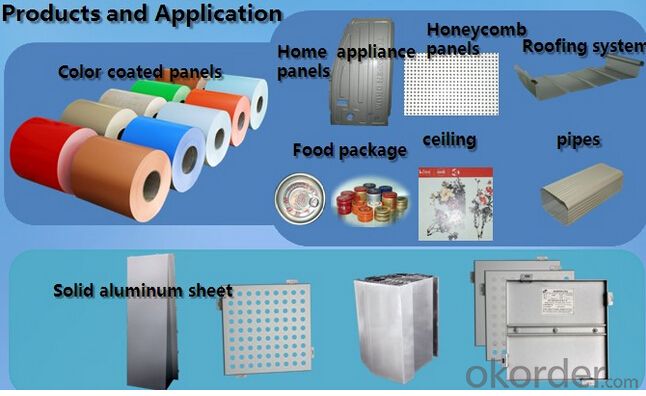

Food Grade Coating Stucco Embossed Aluminum Freezer Sheet is widely used in the strength requirements of the product. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Food Grade Coating Stucco Embossed Aluminum Freezer Sheet:

Aluminum Alloy: 1100 3003 3004 5052 5182

Temper: O-H112

Thickness: 0.15mm---1.5mm

Width: From 18mm---2000mm

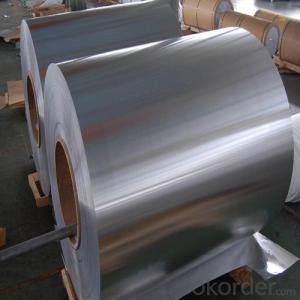

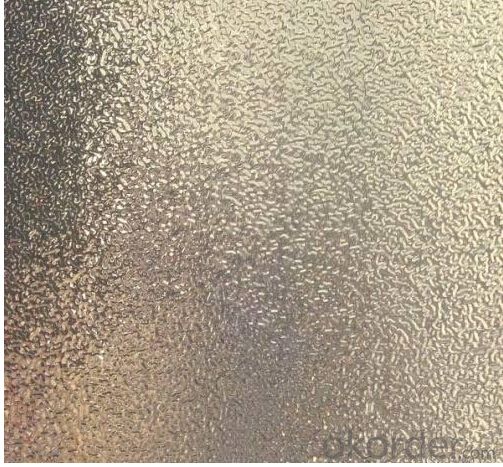

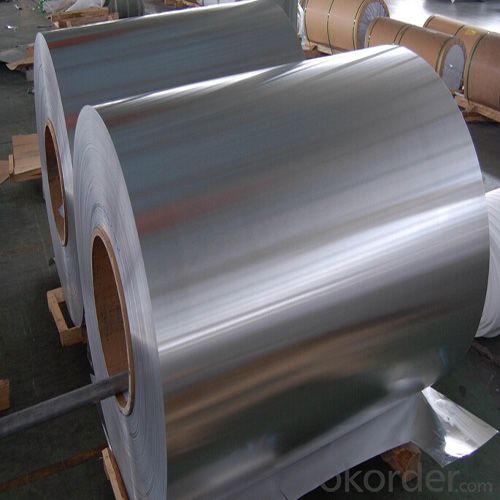

3. Food Grade Coating Stucco Embossed Aluminum Freezer Sheet Images:

4. Food Grade Coating Stucco Embossed Aluminum Freezer Sheet Specification:

ALLOY | SEPCIFICATION | TEMPER | |

THICKNESS | WIDTH | ||

1100, 1050,1060,1070 | 1.0-5.0 | 1000-2200 | H114,H112 |

3003,3004,3105 | 1.0-5.0 | 1000-2200 | H114,H112 |

5052,5005,5754,5083 | 1.0-5.0 | 1000-2200 | H114,H112 |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: What is the difference between aluminum sheet and aluminum curtain wall? The cost is high!

- The upper and lower layers of the composite aluminum plate are high purity aluminum alloy plates, and the middle is a non-toxic low-density polyethylene (PE) core plate, also called an aluminum plastic plate, and the aluminum veneer is a single aluminum sheet. For appearance, the difference between the two is not large, but the color of aluminum plate is diverse. Price respect, curtain wall uses exterior wall board, aluminous plastic board price is in 100 yuan or so, 2.5mm thick aluminium single board price is in 240 the left and right sides, 3mm single board is more expensive.

- Q: What specific criteria or standards must be met when utilizing recycled aluminum in construction?

- <p>Recycled aluminum products used in construction projects must meet specific requirements to ensure safety, durability, and compliance with building codes. These include adherence to ASTM standards for recycled aluminum alloys, such as ASTM B601 for ingots and ASTM B209 for rolled or cold finished products. The recycled aluminum must also have consistent mechanical properties and corrosion resistance comparable to virgin aluminum. Additionally, the products should be free from contaminants that could compromise structural integrity. It's crucial to verify the source and processing methods of recycled aluminum to ensure it meets these standards before use in construction.</p>

- Q: why does the bubble apear a few minutes later after putting aluminum sheet into dilute sulphuric acid?

- it firstly etches off the oxide on the surface of aluminum, and then reacts with aluminum, generating bubble.

- Q: is there aluminum oxide on the surface of aluminum sheet after being polished by abrasive paper?

- aluminum will be oxided as aluminum oxide once being exposed in air.

- Q: What are aluminum sheets made of?

- Aluminum sheets are typically made of pure aluminum or aluminum alloy, which is a combination of aluminum and other elements such as copper, magnesium, or zinc. The exact composition of the alloy depends on the specific application and desired properties of the sheet. Pure aluminum sheets are softer and more malleable, while alloyed aluminum sheets offer increased strength, durability, and resistance to corrosion. The sheets are produced through a process called rolling, where a large block or ingot of aluminum is passed through a series of rollers to reduce its thickness and create the desired sheet size.

- Q: How does the thickness tolerance of aluminum sheet affect its usability?

- The usability of aluminum sheet is greatly influenced by its thickness tolerance, which refers to the acceptable deviation from the specified thickness. This tolerance is typically expressed as a range or a plus/minus value. Having a tighter thickness tolerance guarantees that the aluminum sheet consistently meets the desired specifications. This is crucial in industries such as aerospace, automotive, and construction, where precise dimensions are necessary. Even a slight deviation in thickness can have a negative impact on the performance and functionality of the product. For example, in aircraft manufacturing, the thickness tolerance of aluminum sheets used for structural components is of utmost importance. A thin sheet could compromise the structural integrity, while a thicker sheet could add excess weight, affecting fuel efficiency. Similarly, in the automotive industry, precise thickness tolerance is vital to ensure compatibility and fitment of various components. On the other hand, a looser thickness tolerance may be acceptable in applications where precise dimensions are not as critical. For instance, in general fabrication, signage, or decorative purposes, a wider thickness tolerance may not significantly affect the usability or appearance of the aluminum sheet. Furthermore, manufacturing aluminum sheets with tighter thickness tolerances generally incurs higher costs due to increased precision and quality control measures. Therefore, the desired level of tolerance should be carefully balanced with the intended use and cost considerations. To conclude, the usability of aluminum sheet is directly influenced by its thickness tolerance, particularly in industries that require precise dimensions. Selecting the appropriate tolerance level is essential to ensure that the sheet meets the necessary specifications and maintains the desired performance and functionality of the final product.

- Q: What are the disadvantages of using aluminum sheets?

- One major disadvantage of using aluminum sheets is their relatively low strength compared to other materials like steel. This can limit their application in certain industries or environments where high structural integrity is required. Additionally, aluminum sheets are prone to corrosion, especially when exposed to certain chemicals or salty environments, which can reduce their lifespan and durability. Lastly, aluminum sheets can be more expensive than other materials, making them less cost-effective for certain projects or budgets.

- Q: What are the weight-saving benefits of using aluminum sheets in different applications?

- Using aluminum sheets in various applications offers several benefits for weight-saving. Firstly, aluminum is a lightweight metal with a density much lower than commonly used materials like steel. This means that by replacing steel sheets with aluminum sheets, significant weight reduction can be achieved in different applications. The reduced weight of aluminum sheets is especially advantageous in transportation industries. For instance, in the automotive sector, using aluminum sheets for body panels, chassis components, and other structural parts can significantly lighten the overall weight of vehicles. This weight reduction leads to improved fuel efficiency as it requires less energy to move the lighter vehicle. Additionally, lighter vehicles generally exhibit better acceleration, handling, and braking performance. In the aerospace industry, the weight-saving benefits of aluminum sheets are even more crucial. Every additional kilogram of weight on an aircraft can increase fuel consumption and operating costs. By utilizing lightweight aluminum sheets in the construction of aircraft structures such as wings, fuselages, and engine components, the overall weight of the aircraft can be reduced, resulting in improved fuel efficiency and extended flight range. The construction sector also highly values the weight-saving benefits of aluminum sheets. Due to their lightweight nature, aluminum sheets are often used in building and infrastructure construction. This characteristic not only makes installation easier but also reduces the load on the building's foundation. Moreover, using aluminum sheets in construction can lead to cost savings as lighter materials require less support structure and can be transported more efficiently. Furthermore, the weight-saving benefits of aluminum sheets extend to various other applications such as packaging, electronics, and consumer goods. In packaging, aluminum sheets are commonly used for lightweight and flexible packaging materials, reducing shipping costs and environmental impact. In electronics, aluminum sheets are used in devices like laptops and smartphones, where weight reduction is desirable for portability. Lastly, in consumer goods, aluminum sheets are utilized for producing lightweight and durable products such as furniture, cookware, and sports equipment. In conclusion, the weight-saving benefits of using aluminum sheets in different applications are significant. Aluminum's lightweight nature allows for weight reduction in transportation industries, improved fuel efficiency, better performance, and extended flight range in aerospace applications, cost savings, and easier installation in construction, as well as various advantages in packaging, electronics, and consumer goods. Overall, aluminum sheets provide a versatile and efficient solution for achieving weight reduction and enhancing performance in diverse industries.

- Q: Excuse me: what kind of aluminum sheet is the cheapest? Which materials are more expensive?

- Among them, 3003 for aluminum manganese alloy, the lowest price in the 3 series, and then 3004.3104, for aluminum, magnesium, manganese alloy than 3003 price to be slightly higherThird bit, 5 series, i.e. aluminum magnesium alloy, such as 5005.50525083. 5005 of these prices are slightly lowerThen, the ---2 system and --4 system and --7 system of the 6 series are derived

- Q: is putting Aluminium foil behind the wind shield actually generate more heat and make the car hotter inside or make the car inside cooler? assume you put foil behind all windows.

- Aluminum foil absorbs heat because the foil, like anything else, will absorb energy from a heat source according to thermodynamic principles. What that translates into is this: heat goes from where it is to where it isn't, or heat goes from where it's hot to where it's not. There are three ways for that to happen. One is convection, one is radiation and the third is conduction. If foil is exposed to flame, the hot combustion gases directly heat the foil when they come in contact with it. If the foil is sitting on the top of the range when the oven is on, the oven heats the air around it and convection currents are set. These convection currents take heat away from the oven and transfer it to things which the hot air passes over. Anyone who has had a hair dryer pointed at them knows what this is like. The skin reacts to the hot air. We feel it. Convection.

Send your message to us

Aluminum Decorative Metal Sheets - Food Grade Coating Stucco Embossed Aluminum Freezer Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords