Aluminum Sheets Perforated Embossed Aluminum Stucco Plate for Refrigeratory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

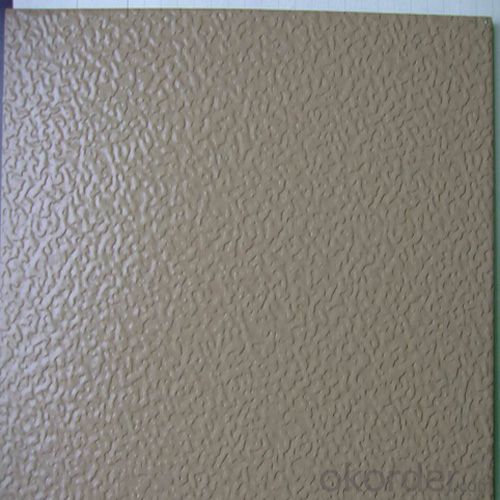

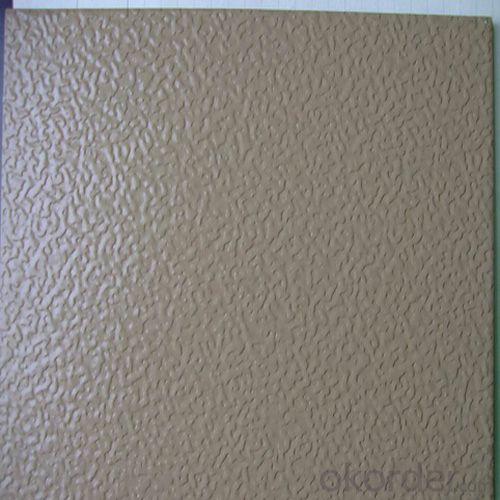

1.Structure of Aluminium Stucco Embossed Plate for Refrigeratory Description:

Aluminium Stucco Embossed Plates are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Aluminium Stucco Embossed Plate for Refrigeratory:

Aluminum Alloy Grade: 1050 1060 1100 3003 5052

Temper: H12, H14, H18, H22, H24, H26

Thickness: 0.8mm~5.0mm

Thickness tolerance: +/-0.01-0.04mm

3. Aluminium Stucco Embossed Plate for Refrigeratory Images:

4. Aluminium Stucco Embossed Plate for Refrigeratory Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: 1mm the aluminum plate is pulled to the height of 45mm. Can I pull it out at 1? How much space should I put in?

- Aluminum sheet material, 1100, 1060, 3003, 5052, 5083, 6061, 8011, 7075 and so on.The thickness of aluminum plate is 0.15mm-500mm, width is 100mm-2000mm, length is: 1000mm-9000mm,Aluminum roll thickness is 0.05mm-15mm, width is: 15mm-2000mmThickness of insulated aluminium plate: 0.3mm-0.9mm width: 500mm-1000mm length: no limitNon slip pattern aluminum plate thickness: 1mm-10mm width: 1000mm-1500mm length: 2000-3000mmEmbossed aluminum plate thickness: 0.1mm-0.9mm width: 500mm-1200mm length: UnlimitedAluminum tube specification: outside diameter range: Phi 3mm to Phi 500mm, wall thickness range: 3mm ~ 50mm, aluminum square tube specification: 10mm*10mm to 200mm*200mm, wall thickness range: 3mm ~ 20mm

- Q: Can aluminum sheets be used for HVAC systems?

- Yes, aluminum sheets can be used for HVAC systems. Aluminum is a popular choice for HVAC applications due to its excellent corrosion resistance, lightweight properties, and thermal conductivity. It is commonly used for manufacturing air conditioner coils, heat exchangers, ductwork, and other components in HVAC systems.

- Q: Which kind of glue is best for bonding aluminum sheets?

- 502 or universal glue

- Q: Can aluminum sheet be used for reflective surfaces?

- Yes, aluminum sheet can be used for reflective surfaces. Aluminum is known for its high reflectivity, making it a popular choice for various applications that require reflective surfaces. Aluminum sheets can be polished to a high shine, allowing them to reflect light and create a mirrored effect. This makes them ideal for uses such as reflectors in lighting fixtures, solar panels, mirrors, and decorative purposes. Additionally, aluminum's reflective properties make it suitable for applications where heat reflection is required, such as in thermal insulation or roofing materials. Overall, aluminum sheets are a versatile and effective option for creating reflective surfaces.

- Q: Can aluminum sheets be used in the automotive industry?

- Yes, aluminum sheets can be used in the automotive industry. Aluminum is a lightweight and durable material that offers several advantages in automotive manufacturing. It is commonly used in the production of car bodies, hoods, doors, and other structural components. The use of aluminum sheets in automobiles helps to reduce the weight of the vehicle, enhancing fuel efficiency and improving performance. Additionally, aluminum has excellent corrosion resistance properties, which is crucial for vehicles exposed to harsh weather conditions. Furthermore, aluminum sheets can be easily formed, welded, and joined, making them versatile and suitable for various automotive applications. Overall, the automotive industry widely embraces the use of aluminum sheets due to their numerous benefits.

- Q: An aluminum clock pendulum having a period of 1.00 s keeps perfect time at 20 degrees celcius. (A) When placed in a room at a temperature of -5.0 Celcius, will it gain or lose time? (B)How much time will it gain or lose every hour.

- A for a swinging pendulum period T =2pi*√(L/g), where L is length of the pendulum, g=9.8m/s^2; metals shrink when cooled, so period will decrease, number of ticks per hour will increase, the clock will hurry up; B? period at t1°=20C° is T1=2pi*√(L1/g); ? period at t2°=-5C° is T2=2pi*√(L2/g); ? the law of linear extension says L2/L1= 1+s*Δt°, where s=23.1·10-6 (1/К°) is specific linear extension of aluminum, Δt°=t2°-t1°; ? thus T2/T1 =√(L2/L1) = √(1+s*Δt°) =f1/f2, where frequency f1= 1 Hz at 20C° or 3600 ticks per hour, hence frequency at -5C° is f2= f1/√(1+s*Δt°); therefore instead of 3600 ticks per hour the clock will do 3600/√(1+s*Δt°) ticks per hour; thus it will gain 3600*(1/√(1+s*Δt°) –1) = = 3600*(1/√(1 -23.1·10-6 *25°) –1) = 1.04 s/hour;

- Q: Can aluminum sheets be used for roof flashing?

- Yes, aluminum sheets can be used for roof flashing. Aluminum is a popular choice for roof flashing due to its durability, corrosion resistance, and lightweight properties. It provides a reliable barrier against water penetration and helps to redirect water away from vulnerable areas on the roof, such as valleys and chimneys. Additionally, aluminum flashing is relatively easy to install and maintain, making it a practical choice for roof flashing purposes.

- Q: Are the aluminum sheets suitable for manufacturing kitchen backsplashes?

- Yes, aluminum sheets are suitable for manufacturing kitchen backsplashes. Aluminum is a durable and lightweight material that is resistant to rust and corrosion, making it ideal for use in kitchen environments. Additionally, aluminum sheets can be easily cut and shaped to fit various design preferences, providing a sleek and modern look to any kitchen backsplash.

- Q: Are aluminum sheets suitable for decorative lighting fixtures?

- Yes, aluminum sheets are highly suitable for decorative lighting fixtures. Aluminum is a lightweight and versatile material that is easy to work with and manipulate into various shapes and designs. It offers excellent corrosion resistance, making it suitable for both indoor and outdoor lighting fixtures. Additionally, aluminum can be easily coated or painted to achieve different finishes, allowing for endless design possibilities. Its reflective properties also contribute to enhancing the overall lighting effect, making it an ideal choice for decorative lighting fixtures.

- Q: What rules or guidelines exist for using recycled aluminum sheets in construction projects?

- <p>Yes, there are regulations and guidelines regarding the use of recycled aluminum sheets in construction. These often include standards for material quality, safety, and environmental impact. The American Society for Testing and Materials (ASTM) and the Aluminum Association provide specifications for recycled aluminum alloys used in construction. Compliance with building codes and local regulations is essential. Additionally, recycled aluminum must meet performance and safety standards equivalent to those of new materials. It's crucial to check with local building authorities and consult the latest industry standards to ensure compliance when using recycled aluminum in construction.</p>

Send your message to us

Aluminum Sheets Perforated Embossed Aluminum Stucco Plate for Refrigeratory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords