Flexible Ducts Roofing Insulation Fiberglass Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Material

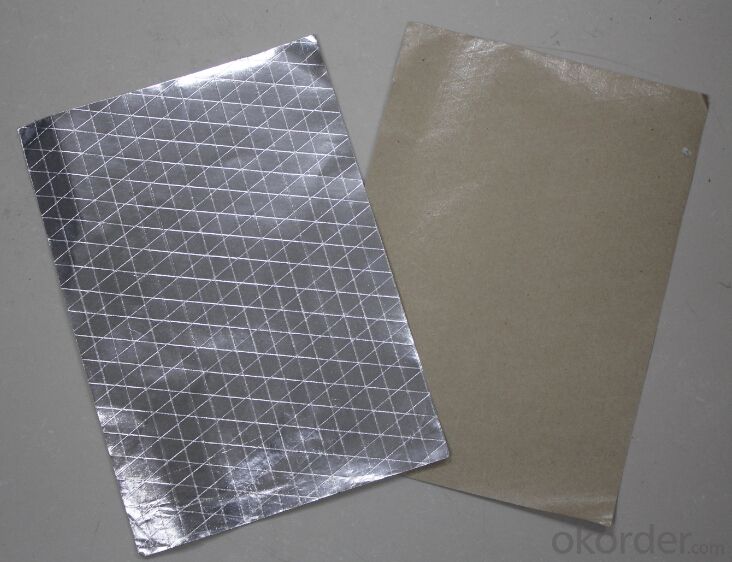

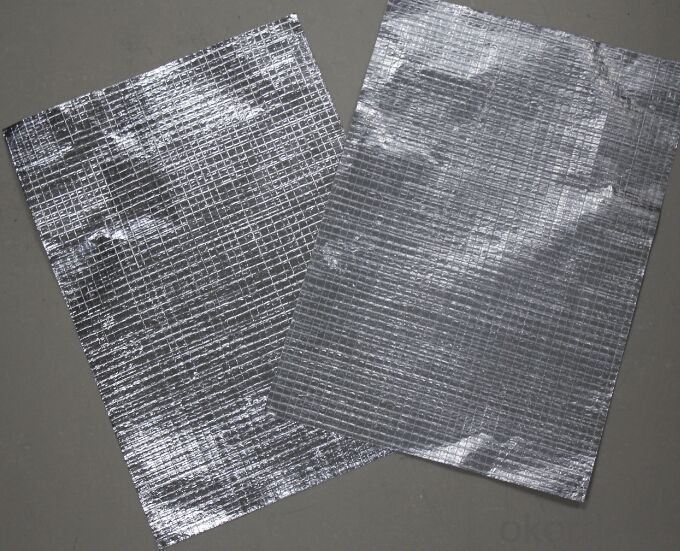

10m length aluminum insulation ventilation duct with low priceis made of aluminum foil +fiberglass+aluminum foi+steel wire

Product Feature

8 inch insulated flexible aluminum air duct heating and cooling systems following feature:

1.Size. (Customer's color requirement can be matched)

2.Color. (Customer's color can be fulfilled )

3.Non-toxic .Harmless to people even long time exposure

4.Excellent light transmission. transparent rate above 92%

5.Excellent weather resistance. performance can’t be change easily by Sunlight and Rain

6.Excellent Design.Personalized design and Human design with mordent concept

Product Advantages

8 inch insulated flexible aluminum air duct heating and cooling systems following advantages:

1.Material .environmentally friendly Acrylic

2.High Ruggedness.hard to attrit ,break and damage

3.Good anti-aging Properties .Long Using life Above 5 years

4.Strong Impact resistance .16 times than that of ordinary glass

5.Logo imprinting .Customer's Logo can be imprinted personally

6.OEM.ODM service. Satisfied related service can be offered in short time

7.Competitive price.Price at various level can cater your various requirement

8.Reasonable Delivery time.Fast to arrive at your office By air or Sea

9.Sample .Sample available for your proof and final decision

10.Trial Order are hotly welcome and allowed

- Q: Sorry, I asked this in the maintenance and repair section, but no luck.Which is better to have in a 2-story home? My last 2-story home was always hotter upstairs than down. (Physics...heat rises)

- the best is more attic isolation so that the heat don't come directly to second floor.

- Q: I know you're not supposed to directly insulate the roof due to the roof getting super heated in the summer, but my walk-in (actually, more like "crawl in") attic is very hot in the summer and very cold in the winter. Is there anything I can do to improve efficiency? I can't help but think I'm wasting a lot of energy just to keep my roof lasting a little longer.

- The reason you do not put insulation directly on the underside of your roof is all about moisture and mold. You need an air gap between the roof and the insulation and allow it to breath. This prevents moisture from condensation that can cause big problems. You could install a radiant barrier that reflects the heat. Do a google search to learn more about it. You could install and attic fan to suck the hot air out in the summer. Most important is to make sure the insulation on the attic floor is the proper thickness.

- Q: I'm thinking of converting my brick walled corrugated iron shed into a changing room for winter hot tub use. I was advised by a friend that the first thing i should do is insulate the roof using glass fibre insulation (the yellow fluffy stuff in the loft) and a simple Plywood ceiling but im not sure how i would stick it to the existing roof (dimensions 170cm x 147cm). So..... how should i insulate the roof of my future changing room????

- If the roof has joists, which I imagine it would, you would put the bats of insulation into those spaces... these can then be stapled into place or if that isn't possible, you can run a wire between the joists to hold the bats in place. If using faced insulation be sure to put the paper side towards the warm area (inside) to prevent condensation.

- Q: I do not have extra space on the roof. Roof also tapers to drains at one end of building.

- Nope. The DOW rigid insulation is an R-5/inch. So 4 inches gets you an R-20. Sorry.

- Q: I need to call around and find a contractor to repair my roof. I thought it might be a good idea to at least have the name of this type of roofing correct so I don't sound like too much of a mark. Thank you in advance for your assistance.

- popcorn ceiling

- Q: ... building code max. (R-50)???

- you need ventilation. the insulation is to keep heat i the living area of your home, your attic should be as cold as outside. make sure you have good soffit vents(intake) and good ridge or roof vents(exhaust). if you already have proper ventilation holes then make sure nothing is blocking them. many times folks push the insulation too far to the ends, blocking the soffit vents. you're loosing heat from your home into the attic which melts the roof snow and the outside temp then quickly turns this into ice. proper insulation as well as ventilation work hand in hand to combat this.

- Q: We have recently moved into a house in Australia with a tin roof. There is a layer of 5cm batts on the rafters in the roof space, but the temp is 10-15 degrees C higher up there than in the house (with all the windows and doors open). I don't want to get air-conditioning, is there another way to insulate the roof and cool the house?

- like they said ventilation is the answer... you allready have a radiant barrier ( metal roof ), now get the heat out. a rigge vent would be best with plent of open soffit all the way around the perimeter. if you're in a dry climate, a humidifier will work as well as an a/c, but much cheaper! give measurments in feet & inches... what do you thing, some one from france is going to help you?

- Q: I already have fiberglass in the attic, but would like to add more.

- BLOWN BY ALL MEANS!!! SOME PLACES WILL EVEN LEND YOU A MACHINE TO BLOW IT WITH IF YOU BUY THE INSULATION FROM THEM.BAT TYPE INSULATION IS OLD SCHOOL!

- Q: The attic was converted into two rooms and I want to add insulation but the space between the ceiling of the rooms and the roof is about 5 inches? How should I do this?

- There are closed-cell expanding foam insulation materials that can be installed through rather small holes in the ceiling. The advantage of this material is that it also serves as a vapor-barrier - a critical function in your case. Not cheap, but very effective. Make sure you install roof vents to prevent excessive heat from developing above the insulation - but with foam, this requirement is far less onerous than with blown in or batt insulation.

- Q: I would like to know which direction the one side with foil faces. The roof or the interior of the room?This is an attic room. Roof being "raw" i mean that it looks like cedar tongue in groove boards...then shingles on top of them. Which way do i face the foil side of the sheet..?thanx

- Super Tuff R Insulation

Send your message to us

Flexible Ducts Roofing Insulation Fiberglass Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords