Fiberglass Facing e-glass Chopped Strand Mat Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

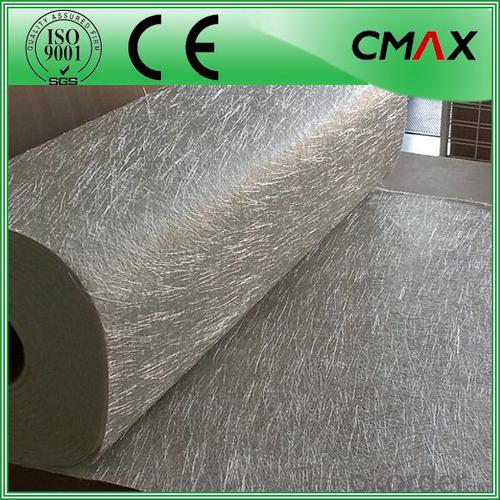

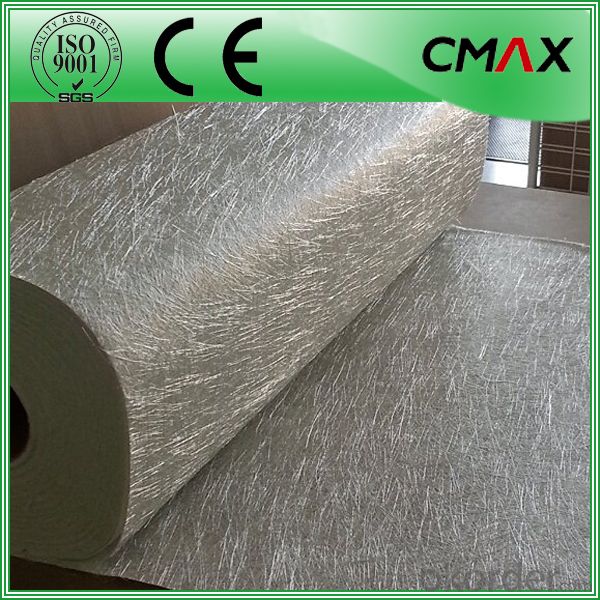

E-glass Fiberglass Chopped Strand Mat Factory

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Technical Data:

| PRODUCT | TYPE | WEIGHT (G/M2) | WIDTH(MM) | ROLL WIEHGT (KG) | MOISTURE CONTENT(%) | BREAKAGE STRENGTH (N) | BINDER CONTENT(%) |

| EMC100 | E/C-GLASS | 100±30 | 200-3300 | 30-90 | < 0.2 | 170 | 8-13 |

| EMC150 | E/C-GLASS | 150±30 | 200-3300 | 30-90 | < 0.2 | 40 | 5-8 |

| EMC225 | E/C-GLASS | 225±30 | 200-3300 | 30-90 | < 0.2 | 60 | 4-7 |

| EMC300 | E/C-GLASS | 300±30 | 200-3300 | 30-90 | < 0.2 | 90 | 3-6 |

| EMC450 | E/C-GLASS | 450±30 | 200-3300 | 30-90 | < 0.2 | 120 | 2-5 |

| EMC600 | E/C-GLASS | 600±30 | 200-3300 | 30-90 | < 0.2 | 150 | 2-5 |

| EMC900 | E/C-GLASS | 900±30 | 200-3300 | 30-90 | < 0.2 | 180 | 2-5 |

Products Shows:

Certificates:

- Q: Is it possible to recycle and reuse black fiberglass tissue to create new products?

- <p>Yes, black fiberglass tissue can be recycled and reprocessed into new products. The recycling process involves shredding the material, which can then be used as a filler or reinforcement in various composite materials. However, the recycling of black fiberglass is not as common as that of other colors due to the dye used, which can complicate the recycling process. Despite this, advancements in recycling technology are making it increasingly feasible to recycle black fiberglass and incorporate it into new products, contributing to a more sustainable use of materials.</p>

- Q: This question asks for a comparison between black fiberglass tissue and other insulation materials, focusing on their properties and performance.

- <p>Black fiberglass tissue is a type of insulation material known for its durability and resistance to heat and moisture. Compared to other insulation materials, it offers a good balance of thermal resistance and affordability. It is lighter than many alternatives, such as mineral wool, and easier to handle, which can reduce installation time and costs. However, it may not provide the same level of sound absorption as materials like cellulose or mineral wool. Additionally, black fiberglass tissue can be less environmentally friendly due to its production process and may not be as effective in certain temperature extremes compared to rigid foam insulations. Overall, the choice between black fiberglass tissue and other insulation materials depends on specific project requirements, including budget, thermal performance needs, and environmental considerations.</p>

- Q: Explain the distinction between black and white fiberglass tissue, including their composition and potential applications.

- <p>Black and white fiberglass tissue are both made from glass fibers, but they differ in color and certain properties. Black fiberglass tissue typically contains carbon black, which provides UV protection and can improve the material's resistance to weathering. It is often used in applications where durability and resistance to sunlight are important, such as in the construction of boats and outdoor structures. White fiberglass tissue, on the other hand, does not contain carbon black and is generally used in applications where aesthetics are a priority, such as in the automotive and aerospace industries. It is also used in situations where the absence of color is beneficial, such as in the production of translucent composites.</p>

- Q: Is it possible to utilize black fiberglass tissue in the construction industry?

- <p>Yes, black fiberglass tissue, also known as black fiber-reinforced polymer (FRP), can be used in construction. It is valued for its high strength-to-weight ratio, corrosion resistance, and durability. Black fiberglass is often used in reinforcing concrete structures, as a component in composite materials, and for strengthening or repairing existing structures. It is also used in the creation of lightweight and strong building materials, such as rebar replacements and for cladding due to its resistance to harsh weather conditions.</p>

- Q: What is the lifespan or strength of black fiberglass tissue?

- <p>The durability of black fiberglass tissue is quite high due to its resistance to various environmental factors. It is known for its strength, corrosion resistance, and ability to withstand high temperatures. Depending on the specific application and environmental conditions, the lifespan can vary. However, under normal circumstances, black fiberglass tissue can last for several years without significant degradation, making it a popular choice for applications requiring long-term durability and low maintenance.</p>

- Q: This question asks if there are any health hazards related to the use of black fiberglass tissues in residential or commercial settings.

- <p>There are no specific health risks associated with the use of black fiberglass tissues in homes or businesses. Fiberglass tissues are commonly used for insulation and are made from fine glass fibers. While there are concerns about inhaling fiberglass fibers, these are typically related to occupational exposure in manufacturing or construction settings where large amounts of fibers are present. In normal use, the risk of inhaling harmful amounts of fiberglass is minimal. However, it's always recommended to follow safety guidelines and use personal protective equipment when handling fiberglass materials to minimize any potential exposure.</p>

- Q: Is it possible to utilize black fiberglass tissue for creating insulation materials suitable for homes in cold climates?

- <p>Yes, black fiberglass tissue can be used for making insulation materials for homes in cold climates. Fiberglass insulation has excellent thermal resistance properties, which help in retaining heat within buildings. The color of the fiberglass does not significantly affect its insulating capabilities. However, it's important to ensure that the fiberglass insulation is properly installed and has a high R-value to maximize its effectiveness in cold climates.</p>

- Q: This question asks for a comparison between black fiberglass tissue and other construction materials, focusing on their properties and applications.

- <p>Black fiberglass tissue, also known as black glass fiber tissue, is a type of composite material made from glass fibers and resin. Compared to other building materials, it offers several advantages. It is lightweight, which reduces the load on structures, and has high tensile strength, making it durable. It is also resistant to corrosion and has good thermal insulation properties. Unlike some materials, it doesn't conduct heat or electricity, which can be beneficial in certain applications. However, it is more expensive than traditional materials like wood or concrete and requires special handling due to the potential health risks associated with the fine fibers. It's commonly used in roofing, insulation, and other applications where its unique properties are beneficial.</p>

- Q: Is it safe to use black fiberglass tissue for food packaging purposes?

- <p>Black fiberglass tissue is not suitable for food packaging. Food packaging materials must be non-toxic and safe for contact with food. Fiberglass, regardless of color, is a type of glass fiber reinforced plastic that can be harmful if ingested or inhaled. It's important to use materials specifically designed for food contact, such as food-grade plastics, paper, or certain types of metal, which are tested and approved for safety in food packaging.</p>

- Q: Can the black fiberglass material be processed and reused in a recycling context?

- <p>Yes, black fiberglass tissue can be recycled, although the process is more complex than recycling other materials due to its composite nature. Fiberglass, made of glass fibers reinforced by a plastic matrix, requires specialized facilities to separate and recycle. The black color is often due to the use of carbon or other pigments, which do not affect recyclability. Recyclers may grind the material into a fine powder or chopped strand to be used as filler in new composite products, or it may be used in construction materials. However, the market for recycled fiberglass is limited, and not all recycling facilities accept it. Proper recycling depends on collection systems and the availability of recycling plants equipped to handle fiberglass.</p>

Send your message to us

Fiberglass Facing e-glass Chopped Strand Mat Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords