Hot Rolled Steel Strip Coils with high quality in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 55 m.t.

- Supply Capability:

- 222555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Applications of Steel Strip Coils:

1:Chemical industry equipment, Industrial tanks

2:Medical Instruments,Tableware, Kitchen utensil,kitchen ware

3:Architectural purpose, Milk & Food processing facilities

4:Hospital Equipment, interior Exterior decoration for building

5:Architectural purposes, escalators, kitchen ware,vehicles

Festures of Steel Strip Coils:

1. Each coil is closely covered by oil paper or plastic film.

2. Outside it is firmly packed with sack cloth or compound paper.

3. Steel strap or PP strap to pack the outside to ensure safety.

4. On/about 1000kgs to be packed with one wooden pallet.

5. Strips can be loaded to 20'FCL without pallet if required by customer.

6. LCL shipment can also be arranged once required by the customer.

Specifications of Steel Strip Coils:

Household Appliance | Refrigerator shutter &side panels, Rice Cooker, Washer, Microwave Ovens, Freezers, Air conditions, Water Heaters, Sterilization Cabinets, Range Hoods, Computer Panels , DVD/DVB panels, TV back panel etc. |

Construction Material | Fireproof Door &Kitchen Cabinet ,Ceiling, Sanitary Unit, Elevator etc. |

Transportation | Car, Ship, Trains, Aircraft Equipment. etc. |

Education and Health Field | Electronic Writing Boards, Projection Screens, Clean Operating Rooms, etc. |

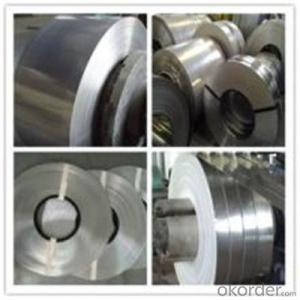

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: How are steel strips processed for surface coating removal?

- There are various methods available for removing surface coatings from steel strips. One commonly used approach is mechanical stripping, which entails using abrasive materials or equipment to physically eliminate the coating. Sandblasting, for instance, involves propelling abrasive particles onto the steel surface using high-pressure air or water, effectively stripping away the coating. Chemical stripping is another technique employed to remove surface coatings. This involves applying chemicals or solvents to the steel strips to dissolve or soften the coating, making it easier to remove. The strips are then rinsed or washed to eliminate any remaining residue. Thermal stripping is also a popular method, which entails heating the steel strips to high temperatures. This causes the coating to burn off or decompose, allowing for easy removal. This technique is particularly effective for organic coatings. In addition to these methods, some companies utilize advanced techniques like laser or plasma coating removal. These methods employ intense heat or energy to vaporize or ablate the coating from the steel surface. Once the surface coating has been removed, the steel strips may undergo further processing such as cleaning, rinsing, or passivation to prepare them for subsequent treatments or applications.

- Q: Can steel strips be used for roofing or siding purposes?

- Yes, steel strips can be used for roofing or siding purposes. Steel strips are durable, strong, and resistant to corrosion, making them an excellent choice for both roofing and siding applications. They provide long-lasting protection against weather elements and require minimal maintenance. Additionally, steel strips offer versatility in terms of design and can be customized to suit various architectural styles.

- Q: How do steel strips perform in high-temperature environments?

- Steel strips perform well in high-temperature environments due to their high melting point and excellent thermal conductivity. They maintain their strength and structural integrity even at elevated temperatures, making them suitable for various applications such as heat exchangers, furnaces, and automotive engines.

- Q: Can steel strips be coated with a protective film?

- Yes, steel strips can be coated with a protective film. This film acts as a barrier, protecting the steel from corrosion, scratches, and other forms of damage. The protective film can be applied through various methods such as electroplating, hot-dip galvanizing, or powder coating, depending on the specific requirements and intended use of the steel strips.

- Q: Can steel strips be used in the production of storage tanks?

- Yes, steel strips can be used in the production of storage tanks. Steel is a durable and strong material that can withstand high pressures and provide structural integrity to the tanks. Steel strips can be formed and welded together to create the desired shape and size of the storage tank.

- Q: How are steel strips coated with protective coatings?

- Steel strips are coated with protective coatings through a process called galvanization. This involves immersing the steel strips into a bath of molten zinc, which forms a protective layer on the surface of the steel. Another method is applying a layer of paint or powder coating to the steel strips, providing a barrier against corrosion and other environmental factors.

- Q: Are steel strips suitable for packaging or shipping purposes?

- Yes, steel strips are suitable for packaging or shipping purposes as they provide strong and durable protection for goods. They can be easily secured around packages and containers, offering stability and preventing damage during transportation. Additionally, steel strips are resistant to corrosion and can withstand heavy loads, making them ideal for packaging and shipping in various industries.

- Q: How do steel strips respond to different corrosion environments?

- Steel strips respond differently to different corrosion environments depending on factors such as the composition of the steel, the presence of corrosive substances, moisture levels, and temperature. In general, steel strips can corrode when exposed to environments with high levels of moisture, oxygen, and aggressive chemicals. However, the response can vary from minimal corrosion to rapid degradation, depending on the specific conditions. Protective coatings, such as galvanization or paint, can be applied to steel strips to mitigate the effects of corrosion and increase their resistance to different environments.

- Q: Are steel strips used in the production of automotive steering components?

- Steel strips are a common choice for producing automotive steering components. They are frequently utilized to construct the structural framework of various steering parts like tie rods, control arms, and steering shafts. Typically, these strips are manufactured from high-strength steel alloys, which grant them the required durability and tensile strength to endure the forces and stresses encountered during vehicle operation. The preference for steel strips in steering component production stems from their outstanding strength-to-weight ratio, resistance to corrosion, and their capability to be shaped into intricate forms. All in all, steel strips play a crucial role in guaranteeing the dependability and performance of automotive steering systems.

- Q: Can steel strips be used for making automotive exhaust systems?

- Yes, steel strips can be used for making automotive exhaust systems. Steel is a common material choice for exhaust systems due to its durability, heat resistance, and ability to withstand the corrosive effects of exhaust gases. Steel strips can be shaped and welded to create the necessary components of an exhaust system, such as pipes, mufflers, and catalytic converters.

Send your message to us

Hot Rolled Steel Strip Coils with high quality in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 55 m.t.

- Supply Capability:

- 222555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords