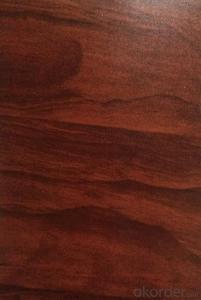

Flat Rolled Aluminum Coil Windsor - PE Aluminum Coil Wooden Rain

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

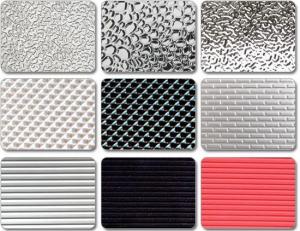

PVDF(Fluorine- Carbon) Coating Coil:

By utilizing Kynar500 (70% Polyvinylidene Difluoride), with a full advanced automatic production line and strict quality control process, Guangmei coated Aluminum Coil feature with super durability and wether resistance, and better properties to antiacid, and anti-alkali, keeping more than 15 years without fading in using as external wall cladding.

PE(Polyester) Coating Coil:

By utilizing excellent Polyester coating, with UV-resistant featured by high molecular polymer as monomer and addition alkyd, Guangmei Coated Aluminum Coil can be classified matt and glossy according to the colors. The compact molicule structure assures paint surface luster and smooth, and saaures good printing on the panel surface. With an warranty of 8-10years for weather resistance, it is specially applied to internal decoration and sign board.

Raw Materials:

1) Aluminum alloy: AA1100, AA3003, or upon request

2) Surface coating: PPG, Akzo Nobel, and Nipon

Colour: Colours from our Colour Chart, RAL, Pantone international colour are available, slao seending us your colour samples are available.

Specifications:

1) Coil width: upon request, max up to1500mm

2) Coil thickness: 0.1mm-1.0mm(±0.02mm)

3) Internal diameter: 405mm, 505mm

4) Coil weight: upon request

Applications:

a. aluminum composite panel

b. aluminum ceiling

c. electric appliance material, advertisment plates, instrument panels

d. colour coated steel strips and all kinds of building material material

- Q: How are aluminum coils processed to achieve desired mechanical properties?

- Aluminum coils are processed to achieve desired mechanical properties through a combination of cold rolling, annealing, and heat treatment. Cold rolling reduces the thickness of the aluminum coil, increasing its strength and hardness. Annealing, a heat treatment process, is then applied to soften the material and improve its formability. Additional heat treatments may be conducted to further enhance mechanical properties, such as tempering to increase toughness or solution heat treatment to improve strength and corrosion resistance. These processing techniques allow manufacturers to tailor the mechanical properties of aluminum coils to meet specific application requirements.

- Q: What are the safety considerations when handling aluminum coils?

- When handling aluminum coils, there are several safety considerations that need to be taken into account. Firstly, it is important to understand that aluminum coils can be quite heavy, especially when dealing with larger sizes. Therefore, proper lifting techniques should be used to avoid strain or injury to the back and muscles. This may involve using lifting aids or getting assistance from others when moving or positioning the coils. Secondly, aluminum coils can have sharp edges or corners, which can cause cuts or puncture wounds if not handled carefully. It is advisable to wear appropriate personal protective equipment, such as gloves, when handling the coils to protect against any potential injuries. Additionally, aluminum is a highly conductive material for electricity and heat. Therefore, it is crucial to ensure that the coils are not in contact with any live electrical sources or exposed to open flames or intense heat. This can help prevent electrical shocks or fires, which could pose significant safety risks. Furthermore, proper storage and stacking of aluminum coils is essential to prevent accidents. Coils should be stored in a stable and secure manner, ensuring that they are not at risk of falling or rolling over. Proper stacking techniques, such as using appropriate supports or pallets, should be employed to prevent them from toppling over. Lastly, it is important to be aware of any specific safety guidelines or regulations provided by the manufacturer or relevant authorities when handling aluminum coils. Following these guidelines can help ensure the safe handling and use of the coils and minimize the risk of accidents or injuries. In conclusion, the safety considerations when handling aluminum coils include using proper lifting techniques, wearing personal protective equipment, avoiding contact with electrical sources and heat, ensuring proper storage and stacking, and following manufacturer guidelines. By taking these precautions, the risk of accidents or injuries can be significantly reduced.

- Q: What are the steps to properly store an unused aluminum coil to prevent it from rusting?

- <p>To store an unused aluminum coil and prevent rusting, follow these steps: 1. Clean the coil thoroughly to remove any dirt or moisture. 2. Apply a thin layer of a rust inhibitor or light oil to the surface. 3. Wrap the coil in a protective plastic or wax paper to prevent moisture and air exposure. 4. Store the coil in a cool, dry place away from direct sunlight and humidity. 5. Ensure the storage area is well-ventilated to prevent condensation. 6. Periodically check the coil for any signs of rust and clean if necessary. By following these steps, you can effectively prevent rusting and maintain the quality of the aluminum coil.</p>

- Q: The export aluminum volume is CIF. If there is no insurance policy, how will the customs premium be collected?

- The customs will not charge your premium the premium you can write but if you are a refund if there will be some impact because of the tax rebate minus the freight and insurance premium so you consider the premium but you can write less Never mind if you need shipping or shipping insurance declaration business can contact me oh

- Q: Explain the distinctions between cold rolled aluminum coils and hot rolled aluminum coils, focusing on the manufacturing process and resulting properties.

- <p>Cold rolled aluminum coils are produced by rolling aluminum at room temperature, resulting in a smoother surface and tighter dimensional tolerances. They have higher strength and hardness due to cold working. Hot rolled aluminum coils, on the other hand, are rolled at high temperatures, which allows for larger thickness reductions and creates a rougher surface. Hot rolled coils are generally softer and more ductile, with lower strength and hardness compared to cold rolled coils. The choice between the two depends on the specific application requirements for strength, surface finish, and formability.</p>

- Q: Can aluminum coils be used for pharmaceutical packaging?

- Yes, aluminum coils can be used for pharmaceutical packaging. Aluminum is a popular choice for packaging in the pharmaceutical industry due to its excellent barrier properties, light weight, and resistance to corrosion. It provides a protective and hygienic environment for pharmaceutical products, ensuring their safety and extending their shelf life.

- Q: Aluminum alloy coil quotation = = how much is the price?

- Different alloy materials, different prices, but also with the thickness and width of a direct relationship!

- Q: The choice between Vinyl and Aluminum? By Mastercraft Exteriors

- Are you asking what I think is better? It really depends on your house your neighborhood and your pocket book. I myself prefer vinyl. Aluminum will dent. A stone from the lawn mower can dent it. Not everytime but it can and over time I guarantee it will. So will that baseball the neighborhood kid throws, (because your child would never do that). Both should be available in the insulation backed version of the product if not through them then through another contractor. So if R-values are a deciding factor you can get about the same from either product. There is a lot more versatility with vinyl around windows and corners.

- Q: Is it safe to use aluminum coil for food storage?

- <p>Using aluminum coil for storing food is not recommended. Aluminum can react with acidic or alkaline foods, potentially leaching aluminum into the food. This can be harmful to health, especially over time. Instead, opt for food-safe materials like glass, stainless steel, or BPA-free plastics for food storage to ensure safety and prevent contamination.</p>

- Q: What are the methods to prevent rust formation on aluminum coils during storage and transportation?

- <p>To prevent rust on aluminum coils during storage and transportation, ensure that the coils are clean and dry before storage. Store them in a cool, dry place away from moisture and corrosive substances. Use protective wrappings or coatings to shield the coils from the environment. Maintain proper ventilation to reduce humidity. Avoid stacking the coils directly on the ground; use pallets or racks to keep them off damp surfaces. Regularly inspect the coils for signs of moisture or damage and address any issues promptly.</p>

Send your message to us

Flat Rolled Aluminum Coil Windsor - PE Aluminum Coil Wooden Rain

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords