Flat Rolled Aluminum Coil Toronto - Coating Aluminium Coil for Compesite Panel 1100 H18

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

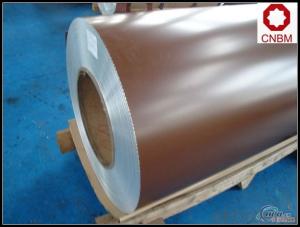

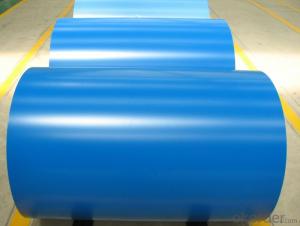

The Specification of Coated Aluminium

Pop-Up Foil Sheets are individual sheets of Aluminum Coil. Wrappers are so easy to use with all your foods because they pop up one-at-a-time and require no cutting or tearing! Use them for wrapping food to go, as portable place mats, wrapping sandwiches, protecting counters during meal preparation, when making snacks or to store food in the refrigerator.

coated emboss aluminum coil/metal roofing

| |

Aluminum Temper and Grade | Alloys: 1100, 1050, 1100, 3003, 3105, 8011 in a range of standard Temper: O-H112 |

Widths | Max up to 1600mm |

Thickness | 0.02-3.0mm |

Coating | PE or PVDF |

Color | AS per the RAL |

Weight | 1.5-4MT/Coil as per your request |

Packing Detail | Wooden pallet either eye to side or eye to sky

|

Application | Building material such as metal ceiling, roofing, wall cladding panel; Automobiles, etc. |

Rolled up tightly and evenly, smooth sides, uneven difference is less than 2mm, no obvious variation or loose inner core, with no concave outside profile. No more than 1 joint per 500m

The Main Features of Aluminium Coated Coil:

High quality with competive prices.

Wide product range of choice.

We are specific manufacture and control.

The Imagin

FAQ:

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C,T/T, West Union,etc.

- Q: This question seeks to understand the environmental impact of discarded aluminum coils.

- <p>Discarded aluminum coils can have significant environmental impacts. They contribute to landfill waste and can potentially leach harmful substances into the soil and water if not properly managed. Aluminum production is energy-intensive, so recycling discarded coils reduces the demand for raw materials and conserves energy. However, if left in the environment, aluminum can also contribute to pollution and disrupt ecosystems. Proper recycling and disposal methods are crucial to mitigate these effects and promote sustainability.</p>

- Q: Related technical standards of aluminium coil

- GB/T 6453-1986 inhalation zirconium aluminum alloy composite stripGB/T 6452-1986 zirconium aluminum alloy powder for inhalationGB/T 3959-1994 industrial anhydrous aluminium chlorideGB/T 3151-1982, water purifying agent, aluminium sulfateGB/T 1871.3-1995 - Determination of aluminium oxide content in phosphorus ores and concentrates -- Volumetric and spectrophotometric methods

- Q: What is the maximum yield strength of aluminum coils?

- The maximum yield strength of aluminum coils can vary depending on the specific alloy and temper of the aluminum. However, in general, aluminum coils typically have a yield strength ranging from 10,000 to 40,000 psi (pounds per square inch). It is important to note that different alloys and tempers of aluminum have different properties and therefore different maximum yield strengths. Additionally, the thickness and width of the aluminum coils can also affect their maximum yield strength. Therefore, it is recommended to consult the manufacturer's specifications or standards for the specific alloy and temper of the aluminum coils to determine their maximum yield strength.

- Q: What is the maximum temperature aluminum coils can withstand?

- The maximum temperature that aluminum coils can withstand depends on several factors, including the specific alloy of aluminum and the intended application of the coils. Generally, aluminum has a melting point of around 660 degrees Celsius (1220 degrees Fahrenheit). However, aluminum coils used in various industries such as HVAC (heating, ventilation, and air conditioning) systems and electrical appliances are typically designed to operate within a temperature range of -30 to 150 degrees Celsius (-22 to 302 degrees Fahrenheit). These temperature limits ensure that the aluminum coils maintain their structural integrity and do not experience any significant degradation or damage. It is important to consult the manufacturer's specifications or guidelines for the specific aluminum coils in question to determine their maximum temperature tolerance.

- Q: Can aluminum coils be painted for custom designs?

- It is indeed possible to paint aluminum coils to achieve personalized designs. The act of painting the coils opens up a world of limitless options for customization and aesthetic appeal. Various colors, patterns, and designs can be applied to the coils, catering to individual tastes and needs. To complete the painting process, the surface must first be cleaned, followed by the application of a primer and the desired paint or coating. Through this method, one can create distinctive and captivating custom designs suitable for a wide array of purposes, including architectural elements, signage, automotive components, and more. Moreover, the paint not only safeguards the aluminum from corrosion but also enhances its durability.

- Q: Are aluminum coils suitable for reflective insulation?

- Yes, aluminum coils are suitable for reflective insulation. Aluminum is highly reflective and has low emissivity, which means it can effectively reflect radiant heat. This makes it an ideal material for reflective insulation, as it helps to reduce heat transfer by reflecting radiant energy away from the insulated space. Aluminum coils are commonly used in reflective insulation products such as foil-faced insulation boards and radiant barriers.

- Q: What are the potential applications of patterned aluminum coils?

- Patterned aluminum coils have a wide range of potential applications across various industries. One of the main uses of patterned aluminum coils is in the construction industry. These coils can be used for roofing, siding, and cladding applications. The patterned surface helps to enhance the aesthetic appeal of buildings and can also provide additional strength and durability. Another potential application of patterned aluminum coils is in the transportation industry. These coils can be used for manufacturing automotive parts such as body panels, trims, and decorative accents. The patterned surface adds a unique and stylish look to vehicles while also providing corrosion resistance and lightweight properties. Patterned aluminum coils can also be utilized in the manufacturing of household appliances and furniture. They can be used for creating decorative panels, cabinets, and countertops. The patterned surface can add a modern and sophisticated touch to these products, making them more visually appealing to consumers. Additionally, patterned aluminum coils have applications in the packaging industry. They can be used for manufacturing packaging materials such as cans, containers, and lids. The patterned surface can make the packaging more eye-catching, helping to attract customers and increase sales. Furthermore, patterned aluminum coils can be used in the production of signage and advertising materials. The patterned surface offers a unique and attention-grabbing appearance, making it ideal for creating signage that stands out and effectively communicates messages. Overall, the potential applications of patterned aluminum coils are vast and varied. From construction to transportation, household appliances to packaging, and signage to advertising, these coils offer a versatile solution for enhancing aesthetics, durability, and functionality in various industries.

- Q: Are aluminum coils resistant to UV rays?

- Yes, aluminum coils are resistant to UV rays.

- Q: having trouble looking for tis information, don't know where to look.Is aluminum accessible to everyone?? Does it cost a lot, is it in minimal areas if so is it hard to transport to all around the world??

- I like this answer - Aluminum is one of earths most common metals can be found just about any were is light and melts fast thats why it,s used for drinking can,s and doe,s not subside to rust right away cost of aluminum oney a matter of how much prossing is done to it and if being mixed with other metal to make it stronger

- Q: Are aluminum coils suitable for electrical transformer applications?

- Yes, aluminum coils are appropriate for use in electrical transformer applications. Aluminum coils possess several advantages over traditional copper coils when utilized in transformers. To begin with, aluminum is a lightweight metal, making it easier to handle and transport. This is particularly advantageous for large transformers where reducing weight is desired. The lightweight nature of aluminum coils also facilitates easier installation and maintenance. Secondly, aluminum exhibits excellent electrical conductivity, albeit not as conductive as copper. However, aluminum coils can compensate for lower conductivity by employing larger wire sizes or increasing the number of turns. This ensures that the transformer operates efficiently and effectively. Moreover, aluminum has a higher thermal conductivity compared to copper. Consequently, aluminum coils can dissipate heat more efficiently, which is crucial for the proper functioning and longevity of transformers. This increased heat dissipation aids in reducing the transformer's operating temperature, thereby enhancing its overall performance. Furthermore, aluminum serves as a cost-effective alternative to copper. Generally, aluminum is less expensive than copper, making it a more economical option for transformer manufacturers. This cost advantage can be particularly significant in large-scale transformer production. However, it is important to note that there are certain considerations to be mindful of when utilizing aluminum coils in transformer applications. Aluminum coils are more susceptible to oxidation and necessitate proper insulation to prevent corrosion. Additionally, aluminum coils may exhibit slightly higher electrical losses compared to copper coils, although advancements in design and manufacturing techniques have mitigated this concern. In conclusion, aluminum coils are indeed suitable for use in electrical transformer applications. They offer benefits such as lightweight construction, excellent electrical conductivity, superior thermal conductivity, and cost-effectiveness. However, it is crucial to implement proper insulation and preventive measures to address any potential challenges associated with aluminum coils, ensuring optimal performance and durability of the transformers.

Send your message to us

Flat Rolled Aluminum Coil Toronto - Coating Aluminium Coil for Compesite Panel 1100 H18

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords