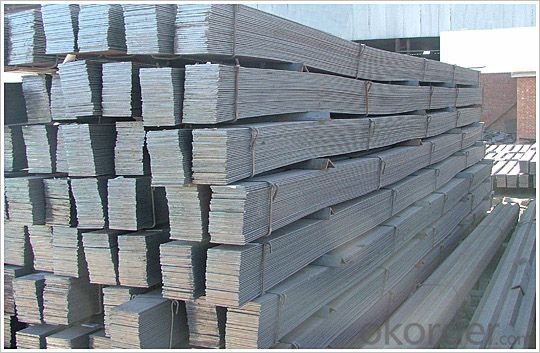

Flat Bar High Quality Steel Flat Bar,Flat Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Seaworthy export packed |

| Delivery Detail: | 20-25 days |

Specifications

High Quality steel flat bar,flat steel,flat bar

1. Q235,Q345,SS400,ASTM A36,S235JR,S275JR

2. USD 495-516/Ton

3. Free Sample

flat steel,Steel Flat Bar, Galvanized Flat Bar,SS400 flat steel,galvanized flat steel

typical size range: | 10*3 – 300*25mm 6 – 12M Long (special lengths can also be provided) |

Available specifications: | EN 10025 GB/T704-2004 JIS G3101 |

Steel grades: | S235JR, S355JR, Q235B, Q345B, SS400 |

Application of Flat Bar

Flat Bar is used for general fabrication, making structures and frames. Mild Steel Flat Bar can be easily cut and drilled, and is particularly suited to welding. Examples of its use include furniture making, machinery manufacturing, shipbuilding, railway spare parts, iron towers, steel structures, and boilers.

1. What grades and standards of steel are used for your production?

Our grades could meet most of customers demand, such as ASTM, GB, JIS, EN etc…Specific grades include commercial quality, low carbon; high carbon and high strength select low alloys.

2. What type of finishes is your product produced in?

We produce steel product in a wide variety of finishes, including hot-rolled black, hot-rolled pickled & oiled, cold-rolled, aluminized, and hot dipped galvanized. If you have a specific finish that is required, please contact us for additional information.

3. What is your order minimum?

As an experienced steel materials manufacturer, we sell in one full container and combination container. Although the total weight on an order will vary due to the type and size, a typical full container load or less container load order will be approximately 15-25 tons.

4. What could we get if we build up relationship with you company?

Frankly, you get competitive price, good quality materials and considerable payment term. Our experienced team will offer you full service from order confirmation to goods arrival your warehouse. You have nothing to worry about during the process.

- Q: Are steel flat bars available in pre-cut lengths?

- Yes, steel flat bars are available in pre-cut lengths.

- Q: Are steel flat bars used in structural engineering?

- Yes, steel flat bars are commonly used in structural engineering. They are versatile and widely used for various applications such as beams, columns, braces, and connections in buildings, bridges, and other structures. Steel flat bars offer excellent strength and durability, making them an essential component in structural engineering projects.

- Q: Can steel flat bars be used for structural support?

- Yes, steel flat bars can be used for structural support. They are commonly used in construction projects to provide stability and support in various applications such as beams, columns, braces, and frames. The high strength and durability of steel make it an ideal material for structural support, ensuring the safety and stability of the structure.

- Q: Can steel flat bars be used in the manufacturing of machinery?

- Yes, steel flat bars can be used in the manufacturing of machinery. Steel flat bars are commonly used in the construction of machinery components due to their strength, durability, and versatility. They can be shaped, cut, and welded to create various machine parts such as brackets, supports, frames, and structural elements. Additionally, steel flat bars offer good resistance to impact, wear, and corrosion, making them suitable for industrial applications in the manufacturing sector.

- Q: Are steel flat bars available in different surface roughness options?

- Yes, steel flat bars are available in different surface roughness options. The surface roughness of steel flat bars can vary depending on the manufacturing process and the intended use of the product. Steel flat bars can be produced with a smooth, polished surface finish, which is commonly used for decorative purposes or in applications where a clean and aesthetically pleasing appearance is desired. On the other hand, steel flat bars can also be manufactured with a rougher surface finish, which is often used in industrial or heavy-duty applications where improved grip or enhanced friction is required. The surface roughness of steel flat bars can be controlled during the production process by using various techniques such as grinding, sandblasting, or chemical treatments. Therefore, customers have the option to choose steel flat bars with different surface roughness options based on their specific requirements and preferences.

- Q: What are the different methods of surface polishing for steel flat bars?

- There are several methods of surface polishing for steel flat bars, including mechanical polishing, chemical polishing, electrochemical polishing, and abrasive blasting. Mechanical polishing involves using abrasive materials such as sandpaper or polishing wheels to remove surface imperfections and create a smooth finish. Chemical polishing involves using chemical solutions to dissolve a thin layer of the surface, resulting in a polished appearance. Electrochemical polishing utilizes an electric current to remove surface material and achieve a polished finish. Abrasive blasting, also known as sandblasting, involves propelling abrasive particles at high speeds to clean and polish the surface of the steel flat bars. Each method has its own advantages and is chosen based on the desired finish, efficiency, and cost-effectiveness.

- Q: Can steel flat bars be used for manufacturing machinery?

- Yes, steel flat bars can be commonly used for manufacturing machinery. They provide structural support, durability, and can be easily machined or welded to create various components and parts necessary for machinery production.

- Q: What are the different types of defects that can occur in steel flat bars during manufacturing?

- There are several types of defects that can occur in steel flat bars during the manufacturing process. These defects can affect the quality and integrity of the bars, and may vary in their severity. Some of the common types of defects include: 1. Surface defects: These defects occur on the surface of the flat bars and can be caused by various factors such as improper handling, scratches, or contamination during manufacturing. Surface defects may include scratches, pits, scabs, or scale. 2. Dimensional defects: These defects relate to the dimensional characteristics of the steel flat bars. They can occur due to equipment malfunction, improper rolling techniques, or inaccurate measurements. Dimensional defects may include variations in thickness, width, or length beyond the specified tolerances. 3. Internal defects: These defects are not visible on the surface and may be present within the steel flat bars. Internal defects can occur due to improper casting, inclusion of impurities, or improper heat treatment. Common internal defects include cracks, voids, or inclusions. 4. Mechanical defects: These defects affect the mechanical properties of the steel flat bars, such as strength, toughness, or ductility. They can occur due to improper heat treatment, incorrect alloy composition, or inadequate cooling during manufacturing. Mechanical defects may include low hardness, poor impact resistance, or brittleness. 5. Straightness defects: These defects relate to the straightness of the steel flat bars. They can occur during the rolling process if there is uneven pressure or misalignment of the rolls. Straightness defects may result in bars that are bent or twisted, making them unsuitable for certain applications. It is important for manufacturers to implement quality control measures to detect and minimize these defects during the manufacturing process. This can involve regular inspections, proper handling and storage of the bars, accurate measurements, and adherence to industry standards and specifications.

- Q: What are the different shapes available in steel flat bars?

- Steel flat bars are available in a variety of shapes, each designed to fulfill specific requirements and applications. Among the different shapes found in steel flat bars are flat, round-edged, square-edged, and round shapes. 1. The flat shape is the most commonly used and fundamental shape of steel flat bars. It features a rectangular cross-section with two parallel and flat surfaces. Flat bars see widespread usage in the construction, manufacturing, and fabrication industries for purposes such as structural support, framework, and general applications. 2. Steel flat bars with round edges possess slightly curved or rounded profiles on the edges. This shape is favored when the flat bar may come into contact with other materials or individuals, as it reduces the risk of injuries or damage caused by sharp edges. Round-edged flat bars find common applications in furniture, automotive, and architectural fields. 3. Square-edged steel flat bars, similar to the flat shape, have sharp, square corners. This shape is ideal in situations where precise right angles are necessary or when the flat bar needs to fit into specific slots or joints. Square-edged flat bars are often used in the construction, machinery, and manufacturing industries. 4. Although not technically a flat bar, steel round bars are extensively utilized in various industries. Round bars possess a circular cross-section and are frequently employed in applications that require strength, durability, and resistance to deformation. They are commonly found in construction, engineering, and automotive fields. It is important to note that these examples represent only a few of the various shapes available in steel flat bars. Manufacturers may offer custom shapes and profiles to fulfill specific project requirements.

- Q: What is the maximum length of steel flat bars available?

- The maximum length of steel flat bars available can vary depending on the manufacturer and supplier. However, standard lengths for steel flat bars typically range from 20 to 24 feet. It is important to note that longer lengths may be available for custom orders or specialty applications, but they may come at an additional cost or require special handling during transportation. Therefore, it is always recommended to consult with the specific manufacturer or supplier to determine the maximum length of steel flat bars that they offer.

Send your message to us

Flat Bar High Quality Steel Flat Bar,Flat Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords