Painted Aluminum Sheets Oregon - Five Bar Anti-Slip Bus Aluminum Tread Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Five Bar Anti-slip Bus Aluminum Tread Plate Manufacturer

lProduct Information

1.Alloy :1060,1100,3003,5052,5754,6061,6063,6082

2.Temper: H14,H18,H12,H16,H22,H26,H24,T3,T4,T6

3.Brand: CMAX

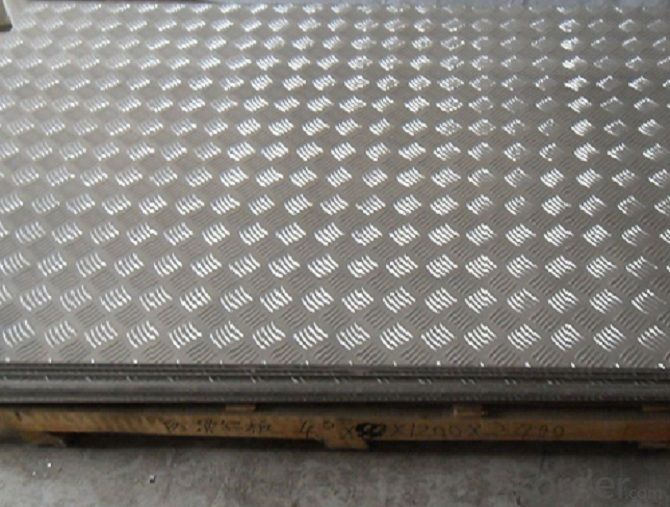

4.Thickness: 0.8-10.0mm. width: 20-1650mm. length:500-16000mm

5.Tolerance: thick +/-0.02mm, width +/-0.5mm.

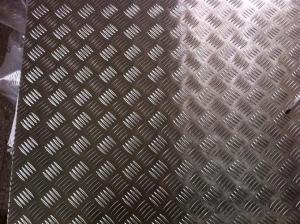

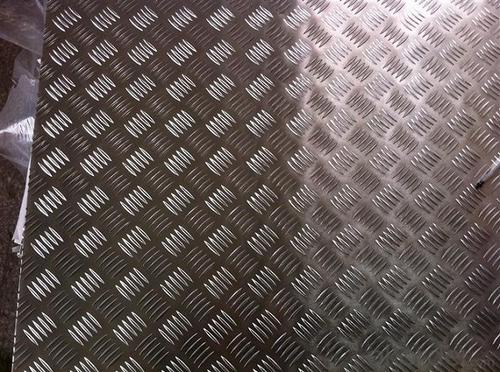

6.Pattern:One bar, Two bars, Three bars, Five bars and Diamond.

7.Surface brightness: bright surface or normal surface.

8.Application: trailer, truck, decking, flooring, stairs, steps, building industry.

9.Loading port: Shanghai port, or main port in China

lPackaging & Delivery Details

Packaging: Standard seaworthy packing

Delivery: About 25 days after received your advance

lCompany Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building

material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

CNBM has been involved in aluminium products for about a decade. With advanced technology and equipment, our products have been sold to the worldwide including America, Europe, as well as South Asia, etc.

lProduct Images

lCertificates

lFAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

- Q: What are the standard dimensions of aluminum sheets?

- The specific industry and application determine the varying standard dimensions of aluminum sheets. However, there are commonly available sizes that are commonly used. For general purposes, aluminum sheets are commonly found in dimensions of 4 feet by 8 feet (1219mm x 2438mm) and 4 feet by 10 feet (1219mm x 3048mm). These dimensions, often referred to as "full sheets," are widely used in construction, manufacturing, and signage industries. Aside from full sheets, smaller sizes of aluminum sheets are also available, such as 2 feet by 4 feet (609mm x 1219mm) and 2 feet by 8 feet (609mm x 2438mm). These smaller sizes are commonly used for DIY projects, crafts, and hobbies. It is important to note that although these dimensions are standard, aluminum sheets can be custom cut to meet specific sizes and shapes for individual project requirements. This provides greater flexibility and versatility across various industries. Ultimately, the choice of aluminum sheet dimensions depends on the specific needs of the project, industry standards, and personal preferences.

- Q: How does the surface finish affect the optical properties of aluminum sheet?

- The surface finish of aluminum sheet can significantly impact its optical properties. A smooth surface finish on aluminum sheet results in better light reflection and less scattering, leading to higher reflectivity. This means that more light is reflected off the surface, making the aluminum sheet appear brighter and more reflective. On the other hand, a rough or textured surface finish on aluminum sheet can cause light to scatter in different directions, reducing reflectivity. This can result in a duller and less reflective appearance. Additionally, the surface finish can affect the appearance of any coatings or films applied to the aluminum sheet. A smooth surface finish allows for better adhesion and uniformity of coatings, enhancing their optical properties. In summary, a smooth surface finish on aluminum sheet enhances its optical properties by increasing reflectivity and reducing scattering, resulting in a brighter and more reflective appearance.

- Q: I'm trying a new brownie recipe for the holidays this year. My experiences with baking brownies is never good. After I've taken them out of the oven and let them cool, I can never get them out of the pan without them falling apart on me! Can I bake brownies in the pan if it's lined with aluminum foil? I think that may make them easier to get out. Also, the new recipe I'm trying is actually a cheater recipe that starts with devils food cake mix. These are going to be gifts for friends and coworkers, and I just want perfectly squared, clean brownies! Any tips or ideas?

- Aluminum is an amazingly good conductor of heat. Which means that the bottom of the brownies will be burnt before the middles are done. I agree with others: try a parchment-paper-lined pan, or grease the pan well (use margarine spread with clean fingers or a spray), and then dust the pan with cocoa. Usually you would use flour, but that will leave a white residue on the brownies--the cocoa will blend in and actually add a bit more chocolate flavor. Or, dust with some of the cake mix before you mix up the batter. Also, be sure to let the brownies cool in the pan before you try to cut them.

- Q: HI! I have a few of my most favorite aluminum baking pans and lids that are brown with baked on grease etc...and I have not the strength or endurance to stand and buff them with a scratchy pad til they gleam....are there any cleaning chems or soaps that will do this for me?? Thanks!! Mama never told me there'd be days like this!

- Thanks, have all of the above that you mentioned...just that a few are favorites as I can pick them up easily - bad shoulders and elbows have weight bearing issues....I don't even cook all that much, but seem to burn a lot - even when boiling eggs....it is a miserable commentary on a day in the life of Aunt Susie....

- Q: Can the aluminum sheets be used for manufacturing chemical reactors?

- Yes, aluminum sheets can be used for manufacturing chemical reactors.

- Q: Can aluminum sheets be used in marine environments?

- Yes, aluminum sheets can be used in marine environments. Aluminum is a commonly used material in marine applications due to its excellent corrosion resistance properties and lightweight nature. It can withstand the harsh conditions of saltwater, making it suitable for boat building, marine structures, and other marine-related uses.

- Q: Are aluminum sheets suitable for food-grade applications?

- Yes, aluminum sheets are suitable for food-grade applications. Aluminum is a widely used material in the food industry due to its excellent properties. It is non-toxic, corrosion-resistant, and has a high thermal conductivity, making it a suitable choice for food processing and packaging. Aluminum sheets can be used to make food-grade containers, trays, and packaging materials. They are also commonly used for cooking utensils, such as baking sheets and foil, which are safe to use in direct contact with food. Additionally, aluminum sheets can be easily cleaned and sanitized, making them a hygienic choice for food-grade applications.

- Q: How do you calculate the weight of an aluminum sheet?

- To calculate the weight of an aluminum sheet, you need to consider its dimensions (length, width, and thickness) and the density of aluminum. First, measure the length, width, and thickness of the aluminum sheet in inches or millimeters. Make sure to use the same unit of measurement throughout the calculation. Next, convert the dimensions to feet or meters if necessary. For example, if the dimensions are in inches, divide each value by 12 to convert it to feet. Multiply the length, width, and thickness together to find the volume of the aluminum sheet. If the dimensions are in different units, convert them to the same unit before multiplying. Then, look up the density of aluminum. The density of aluminum is approximately 2.7 grams per cubic centimeter or 2700 kilograms per cubic meter. Convert the volume of the aluminum sheet to the same unit as the density. For example, if the density is in kilograms per cubic meter and the volume is in cubic feet, convert the volume to cubic meters by multiplying it by 0.0283. Finally, multiply the volume of the aluminum sheet by the density of aluminum to get the weight of the sheet. The result will be in grams or kilograms if the density was in grams per cubic centimeter, or in kilograms or metric tons if the density was in kilograms per cubic meter. It's important to note that this calculation assumes a uniform thickness throughout the aluminum sheet. If the sheet has varying thicknesses, you would need to calculate the weight of each section separately and then sum them up to find the total weight.

- Q: Are aluminum sheets resistant to saltwater corrosion?

- Yes, aluminum sheets are generally resistant to saltwater corrosion. Aluminum has a natural ability to form a protective oxide layer when exposed to air or water, including saltwater. This oxide layer acts as a barrier, preventing further corrosion and protecting the underlying metal. Additionally, aluminum is lightweight and durable, making it a popular choice for various marine applications such as boats, shipbuilding, and offshore structures. However, it is important to note that the resistance to saltwater corrosion can vary depending on the specific alloy and surface treatment of the aluminum sheets. Therefore, proper selection of the appropriate alloy and protective coatings can further enhance the corrosion resistance of aluminum sheets in saltwater environments.

- Q: This question asks for the common types of aluminum sheet windows and doors that are available in the market.

- <p>Common types of aluminum sheet windows and doors in the market include sliding windows, casement windows, fixed windows, and awning windows. For doors, there are sliding doors, swing doors, folding doors, and automatic doors. Each type has specific features and applications, such as sliding windows being space-saving and easy to operate, while casement windows offer better ventilation. Sliding doors are popular for their smooth operation and minimal space requirement, and swing doors are traditional and widely used for their durability and security. These aluminum products are valued for their strength, durability, and low maintenance requirements.</p>

Send your message to us

Painted Aluminum Sheets Oregon - Five Bar Anti-Slip Bus Aluminum Tread Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords