Fiberglass Waterproofing Membrane Fabric - Fireproof PVC Coated Fiberglass Cloth for Shipyard

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: PVC coated fiberglass fabric is finished with UL94-V0 flame retarded PVC coating. PVC coated imparts the glass fabric durable, waterproof, UV resistance etc. PVC coated glass fabric is good used for outdoor weather fire resistance cover. Colors can be green, orange, red etc.

Features: high temperature resistance,heat resistance

Application: It could be used in fields of electrical, ship building, automobile, chemical, construction and fire proof.

PRICE: USD2 per square meter

UNIT: square meter

MOQ: 500square meters

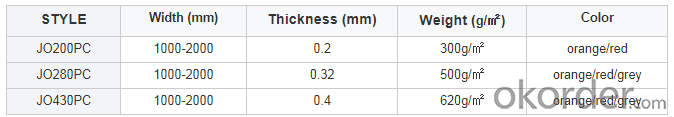

Weight: 300gsm-1100gsm

Width: 1m -2m or customized

Yarn Type: E-glass

Standing temperature: 220℃- 550℃

Product name: PVC Coated Fiberglass Fabric

Coating/Finish/Surface Treatment: PVC coated

Roll length: 50 meter or customized

Color: red or customized

Weave Type:twill woven

Alkali content: Alkali free

Processing service: cutting

Material: fiberglass PVC

Thickness: 0.2mm-1mm

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Rolls packed In cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q: Are fiberglass fabrics suitable for use in marine environments?

- Yes, fiberglass fabrics are suitable for use in marine environments. They are highly resistant to water, chemicals, and UV rays, making them ideal for boat building, sail making, and other applications in marine settings. Additionally, fiberglass fabrics offer excellent strength-to-weight ratio, durability, and dimensional stability, making them a popular choice in the marine industry.

- Q: Can fiberglass fabric be used for heat-resistant gloves?

- Yes, fiberglass fabric can be used for heat-resistant gloves. Fiberglass has excellent thermal resistance properties, making it suitable for applications that require protection against high temperatures.

- Q: The function of roof glass fiber non-woven fabric isolating layer

- Non woven fabrics professional manufacturers waterproof breathable membrane is paved in the building envelope insulation (insulation) layer outside the functional membrane.

- Q: Is fiberglass fabric resistant to UV degradation in outdoor applications?

- Yes, fiberglass fabric is generally resistant to UV degradation in outdoor applications.

- Q: Can fiberglass fabric be used for reinforcement in oil processing tanks?

- Yes, fiberglass fabric can be used for reinforcement in oil processing tanks. Fiberglass fabric is known for its high strength-to-weight ratio, corrosion resistance, and durability, making it an ideal material for reinforcing structures in harsh environments such as oil processing tanks. The fabric can be applied to the tanks either by wet lay-up or vacuum infusion process, ensuring proper adhesion and integration with the tank structure. Additionally, fiberglass fabric is non-conductive and non-magnetic, which makes it suitable for use in tanks containing flammable or sensitive materials. Overall, fiberglass fabric offers a cost-effective and reliable solution for reinforcing oil processing tanks.

- Q: Can fiberglass fabric be used for making automotive interiors?

- Yes, fiberglass fabric can be used for making automotive interiors. It is a versatile material that offers several advantages such as high strength, durability, and resistance to heat and chemicals. Additionally, fiberglass fabric can be molded into various shapes and designs, making it suitable for creating customized automotive interiors.

- Q: What are the different fiberglass fabric finishes for chemical resistance?

- There are several different fiberglass fabric finishes available that provide chemical resistance. These finishes are designed to protect the fiberglass fabric from the effects of various chemicals, making it suitable for use in industries where exposure to corrosive substances is common. Some of the different fiberglass fabric finishes for chemical resistance include: 1. Vinyl finish: This finish involves treating the fiberglass fabric with a vinyl resin coating. Vinyl is known for its excellent resistance to many chemicals, including acids, alkalis, oils, and solvents. The vinyl finish creates a barrier between the fabric and the chemicals, preventing them from causing damage or degradation. 2. Fluoropolymer finish: Fluoropolymer finishes, such as PTFE (polytetrafluoroethylene) or FEP (fluorinated ethylene propylene), offer exceptional chemical resistance. These finishes create a non-stick surface that repels most chemicals, making them ideal for applications where the fabric may come into contact with aggressive substances. 3. Neoprene finish: Neoprene is a synthetic rubber known for its excellent resistance to oils, acids, alkalis, and solvents. Fiberglass fabric with a neoprene finish can withstand exposure to a wide range of chemicals without deteriorating or losing its structural integrity. 4. Polyurethane finish: Polyurethane finishes provide good chemical resistance and also offer additional benefits such as improved abrasion resistance and flexibility. This finish is often used in applications where the fabric needs to withstand exposure to chemicals and physical wear and tear. 5. Silicone finish: Silicone finishes provide excellent resistance to high temperatures and a wide range of chemicals. They create a protective layer on the fiberglass fabric that prevents chemical attack and degradation, making it suitable for use in environments with aggressive substances or extreme conditions. It is important to note that the choice of fiberglass fabric finish for chemical resistance depends on the specific chemicals it will be exposed to and the operating conditions of the application. Consulting with a knowledgeable supplier or manufacturer can help determine the most appropriate finish for a particular chemical-resistant fiberglass fabric.

- Q: How is fiberglass fabric used in the production of insulation boards?

- The excellent thermal resistance, durability, and fire-retardant properties of fiberglass fabric make it widely used in the production of insulation boards. In the manufacturing process, it serves as a reinforcement material and is combined with a binder, such as resin or adhesive, before being compressed to form the boards. This ensures that the insulation material remains stable and prevents it from shifting or settling over time. Additionally, fiberglass fabric enhances the insulation properties of the boards by minimizing heat transfer. This helps to maintain comfortable temperatures in buildings throughout the year, leading to energy efficiency and reduced heating or cooling costs. Moreover, the fire-retardant characteristics of fiberglass fabric provide an extra layer of protection in insulation boards. It acts as a barrier against flames and reduces the risk of fire-related damage. In summary, fiberglass fabric is essential in the production of insulation boards due to its ability to reinforce structures, provide thermal insulation, and offer fire-resistance. It is a versatile and superior choice for various applications in residential, commercial, and industrial buildings where insulation is required.

- Q: Can fiberglass fabric be used for making soundproofing materials?

- Yes, fiberglass fabric can be used for making soundproofing materials. Its dense and fibrous composition helps absorb sound waves, reducing noise transmission and enhancing sound insulation capabilities.

- Q: How is fiberglass fabric tested for quality assurance?

- Fiberglass fabric is tested for quality assurance through various methods including visual inspection, physical testing, and chemical analysis. Visual inspection involves examining the fabric for any defects such as holes, tears, or uneven weaving. Physical testing involves evaluating the fabric's strength, flexibility, and durability through tests like tensile strength, elongation, and abrasion resistance. Chemical analysis is conducted to ensure that the fabric meets specific standards and does not contain any harmful substances. These comprehensive tests help ensure that fiberglass fabric meets the required quality standards before it is used in various applications.

Send your message to us

Fiberglass Waterproofing Membrane Fabric - Fireproof PVC Coated Fiberglass Cloth for Shipyard

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords