Fire Resistant Gypsum Board for Drywall

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

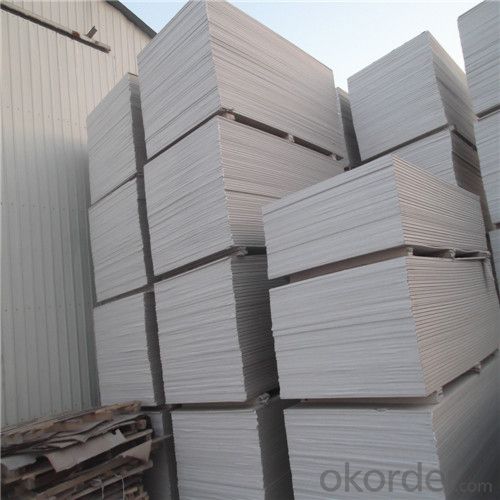

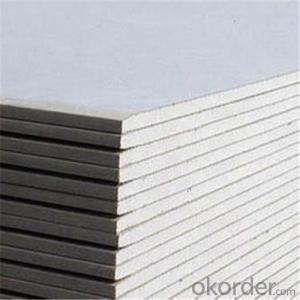

CMAX Gypsum Board Drywall Introduction.

Your drywall can be virtually any shape, anywhere. Choose from a wide range of heavy-duty system options that provide code-compliant performance in both fire rated and non-fire rated applications with labor-saving advantages.

1.Gypsum Board Drywall Specification.

Convenient Construction | The plaster board can be constructed easily by nailing ,cuting and planing,and thus it becomes the first choice among home decoration materials. |

Raw material | The gypsum board is characterized for lightness and high intensity,dryness operation, green environmental protect, convenient construction and good processing quality. |

Size | 595x595 |

605x605 | |

1200x2400 | |

1220x2440 | |

Thickness | 7,7.5,8,9,9.5,10,12,12.5,13,15,15.9 |

Surface treatment | Paper/PVC laminated/foil back |

Production capacity | 10,000m2/day |

7 .specification

SIZE(mm) | KGS/PC | PCS/20GP | SQM/20GP |

1200*2400*7 | 17 | 1180 | 3398 |

1200*2400*7.5 | 18 | 1150 | 3312 |

1200*2400*8 | 18.2 | 1080 | 3110 |

1200*2400*9 | 22.1 | 970 | 2793 |

1200*2400*9.5 | 22.8 | 940 | 2707 |

1200*2400*10 | 23.5 | 900 | 2592 |

1200*2400*12 | 29.5 | 720 | 2073 |

1200*2400*12.5 | 30 | 710 | 2044 |

1220*2440*7 | 17.55 | 1160 | 3453 |

1220*2440*7.5 | 18.14 | 1130 | 3363 |

1220*2440*8 | 18.58 | 1060 | 3155 |

1220*2440*9 | 22.83 | 950 | 2827 |

1220*2440*9.5 | 23.55 | 920 | 2738 |

1220*2440*10 | 23.83 | 900 | 2679 |

1220*2440*12 | 30.5 | 700 | 2083 |

1220*2440*12.5 | 31 | 690 | 2053

|

2.Gypsum Board of ceiling & wall partition system.

CMAX System is a modern, non-load bearing and quickly assembled on site. The system consists of Gypsum Board screw fixed to lightweight galvanized metal sections and joint finished with drywall system is suitable for all internal applications for commercial and residential.

Exquisite, Modern and Adjustable

CMAX drywall system provides smooth, seamless and crack-free wall surface. Thanks to the distinctive property of gypsum Board, it allows easy further decoration by either painting or wallpaper work. Moreover, a renovation can be done easily without any disturbance of office building structure.

Durable and Standard Quality

Materials and accessories of CMAX wall system are manufactured by state of the art technology in accordance with international standards, such as, British Standard and The American Society for Testing and Materials. Customers therefore can be assured of safety, standard quality and high durabiltity of Wall systems.

Lightweight, Easy to Install and Economic

CMAX wall weight much less than masonry partitions of comparable thickness, thus providing real savings in structural design. This enables quick and easy installation, and produces time and cost savings.

Specially Designed and Patented Materials of Gyproc

High quality galvanized CMAX frame metal sections of drywall system are manufactured by state of the art technology called drywall STEEL, to reinforce the cross section of metal sections. C-Stud is also specially designed to be easy when connected, which suits applications requiring extra strength or for length extension of C-Stud. Ready-punched holes from factory provide excellent incorporation of services.

Applicable to Various Usages as Required

CMAX wall system can be designed to suit various types of office application.

Office buildings requiring extra fine resistance, standard drywall system can provide a half-hour fire resistance. Other drywall Systems are also available to provide resistance up to 2 hours.

Other special properties such as heat insulation wall, high moisture resistant wall, acoustic wall, can also be provided by drywall system.

- Q: Plywood flat ceiling and gypsum board flat ceiling What is the difference between the best can be said that the next construction technology gypsum board ceiling construction process I know the plywood flat ceiling did not come into contact with the trouble to help analysis Thank you

- Three plywood ceiling generally wooden keel to do the shelf, you can do clear water, mixed with water, you can also scratch the white putty but the effect is not easy to crack the gypsum board,

- Q: What is the material gypsum board scraping white?

- Now the wall decoration, including scraping and latex paint, the former is a simple decoration cheap but the effect is not good, the latter price is relatively high but the effect is very good, the former material needs putty, which requires special putty and latex paint. program: View the wall with no gaps, such as the wall on the mouth, gypsum board shape gypsum line. If there is a gap, first filled with gypsum and then brush the white latex glue bandage. View the wall with or without rust [nail steel head] If so, use the machine and then make up the plaster. (Scraping gypsum). 【Note: all the roofs of the house must be full of gypsum, because the ceiling shovel out after the very uneven] can not directly scraping white. Gypsum and big white are very different. Before the scratch, the work of gypsum is: all paste the bandages, gypsum board, cement surface. Have to scratch the gypsum. (Scraping white). It is important to draw at least twice. The first pass to be scratched, do not have missed the. The first time to finish, to check the roof and the wall with or without rust. Whipped the second time. After the white finish, to ventilation, do not boring like a wind window can open for a while off, different weather different treatment (White after the dry dry sandpaper). 【Polishing is a brush [spray] latex paint must be done before work. But at the same time polished sandpaper is a very important part of scraping white. The construction workers in the scraping of the white sweep of the scraper of the Road purlin small packets have all worn away. (Protected). So that latex paint stained with bad rub. Brush <spray> latex paint. [Note: The above is the main program of scraping white. "Good white" also need other targeted "procedures".

- Q: The top room in my house has got a ceiling in pretty bad shape. The house roof is ok, but over time the pressure has created a myriad of small cracks. Filling them up one by one is a huge job, so I have two choices: 1) apply a new plasterboard to the ceiling. 2) re-do the ceiling, take off the old one and put a new one.1) sounds an easier solution, but the builder wants to do 2) to avoid cracks reappearing. What would you recommend?

- You should first investigate when and why these cracks appeared. If it's recent, you could end up with cracks in the new wallboard. If they've been there for years and have not gotten worse recently, you'll be o.k. to proceed--and I agree that new wallboard over the old (plaster? or wallboard?) could be the best solution. use drywall screws, not nails, in order to avoid nail pops. Remember to add an extension ring or reposition any ceiling light fixtures to meet the new surface depth. One reason to take it all out and start over is that you could then easily insulate the ceiling-- and ceiling insulation is one of the best returns on your investment for reducing heating & cooling costs.

- Q: when skimming walls, can you do it over backing paper or does it have to be directly on the plasterboard??

- Apply oil based Kilz first. It seals off the paper so that the moisture cannot penetrate.

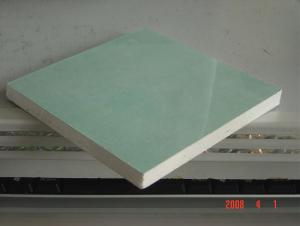

- Q: What is the difference between PVC paper gypsum board and veneer gypsum board?

- First, the price of the former than the latter, Second, the former waterproof, the latter is not waterproof

- Q: Is there anyone out that may be able to give a idea as to how much money I should expect to pay to have plaster board installed in a 9ft wide and 101/2 long and approx 9ft highkitchen that is stripped to furing strips and cinderblock. Thank You,,

- Since it is a small area you can look for a higher price than average. maybe as much as $30 per sheet(labor only) finished ready to paint.

- Q: Gypsum board partition how much money a square?

- The partition is a building space with materials separated into two parts, used to partition the wall is also varied, today to talk about gypsum board wall, that gypsum board wall how the price of it? Ordinary snowflakes 75 keel 20 yuan / square meters, double gypsum board ordinary 20 yuan / square meters, labor costs 20 - 30 yuan / square meters (points with or without noise rock wool), if the high-grade materials, the price 90--160 yuan / square meters or so. There are professional wall keel system, the price of 200 yuan / square meters.

- Q: im wanting to do a big art piece and though a plasterboard may be the best thing but i was wondering about when it comes to painting it is there anything id need to do before hand? and how would watercolour or acrilic paint look on it??

- If you mean drywall with the paper backing on both sides, that would be really heavy, fragile, and be just like painting on paper. I think masonite, aka hardboard, is better. It comes in 1/8 and 1/4 and you would have to prime it first. Any good white latex paint would be as good as artist's acrylic gesso. Prime both sides equally to prevent warping. It would still probably benefit from a wood framework glued to the back before priming. If the frame is stiff enough, prime just the front.

- Q: Gypsum board in the CAD what said

- With a little bit of filling. And then marked with the text. 【Gypsum board ceiling. To

- Q: Which is better? Which cost accounting? What are the advantages and disadvantages? Thank you

- Caigang sandwich board is good, at least after the partition to do inside the office inside the winter is relatively warm, unless the winter you have the company warehouse heating! Color steel sandwich board material price 30 yuan / ㎡, gypsum board package package material about 40 yuan / square, aluminum alloy grille more expensive, so the color steel sandwich board construction is convenient, low cost of materials, insulation effect, sound insulation effect is better than The other two

Send your message to us

Fire Resistant Gypsum Board for Drywall

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords