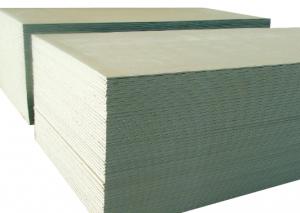

Plasterboard for Drywall Partition

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1Container m²

- Supply Capability:

- 300Containers/Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

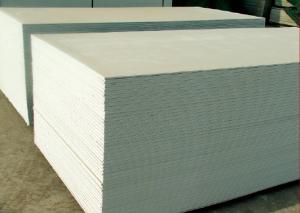

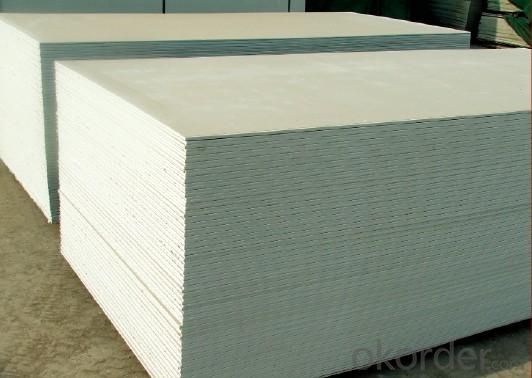

Description of Gypsum Board:

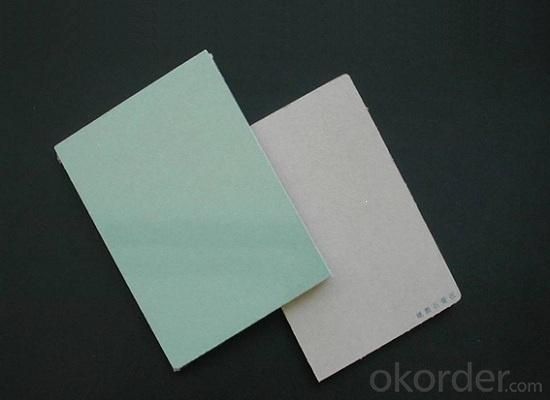

1.We have three kinds of gypsum board, regular gypsum board, fire-proof gypsum board and moisture resistant gypsum board. And our product are mainly used for Ceiling system, Partitio system, Dry lining system and we also provide its allied system such as: Channels, joint compound, joint tape, screws and so on.

2.Gypsum board edge:

Tapered edge (recessed edge) And Square edge (straight edge)

Raw Materials of Gypsum Board:Using high purity gypsum powder as main material and mixed with fiber and highquality additive

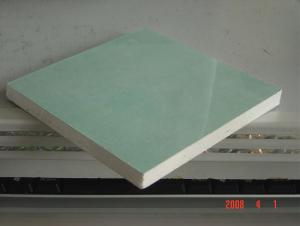

SIZE: (mm)1200*2400 1220*2440 1200*3600 1220*3600 1200*2500 1220*2500 Thickness: ( mm) 6.4 to 16

Package of Gypsum Board

1.Naked with bulk in container by hand

2.Load with pallet by forklift

Applications of Gypsum Board:

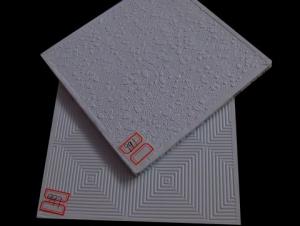

1: Ceiling system,

2: Partition system,

3: Dry lining system

Production Flow:

We have 5 production line for gypsum board, 60 containers can be produced per month.

Our product is of good quality, competitive price as well as high efficient works, therefore it is best choice to work with us.

- Q: How do you paint a stone on a gypsum board?

- In order to ensure the quality of the stone pits on the gypsum board, please follow the following construction methods: 1, waterproof gypsum board. 2, grass-roots treatment. 3, full of putty again; to be greasy layer of white on the layer of sanding, remove the mark; 4, spray primer 2 times, interval of 2 hours, the thickness of about 30 microns, dry at room temperature for 12 hours. 5, polished: 400 - 600 mesh sandpaper, gently wipe the surface of the real stone can be raised sand. Note Intended to force can not be too fierce, otherwise it will damage the film, causing the bottom of the loose, serious will cause poor adhesion, really stone off. 6, spray paint twice: the next pot spray gun, pressure 4-7 kg / square centimeter, the construction is not less than 10 degrees Celsius, interval of 2 hours, the thickness of about 30 microns, completely dry to 7 days.

- Q: Ordinary gypsum board specifications

- Normal 1220MM * 2440MM, there are 3000MM * 1220MM, the thickness of 0.95CM, 1.2CM more

- Q: can i tile straight on plasterboard?

- You can if it's not in a shower, or other location subject to high moisture and it would be best to roll on a primer/sealer first.

- Q: What is the price of the living room ceiling now?

- Living room ceiling can do gypsum can also be integrated, the practice of different prices are not the same, the shape of the complex price is relatively high, but also depends on the local labor costs, material is not expensive labor costs. Wood keel + gypsum board, generally per square meter in accordance with 00 yuan or so, gypsum board requires a good quality, you have to according to II 0 or so. Light steel keel + gypsum board, generally per square meter in accordance with the II 0 - according to 50, if it is shaped, in the bar 0 to II II have between. There is also the use of integrated ceiling to do the living room, as if generally in the 0000-00 or so per square meter. It is recommended that you choose the appropriate ceiling according to the decoration style

- Q: Im thinking of mounting by living room t.v to the wall, but the only problem is the wall is plasterboard and it's pretty weak.Any solutions to this problem?Thanks

- Easist is to remove the plasterboard where going to mount the TV, and replace it with 1/2 plywood screwed to the studs behind. Then buy some joint compound and cover the plywood and paint it after dried. Now you have a secure mounting platform for the TV.

- Q: Used to ceiling

- 1. ordinary paper gypsum board: ivory white paper, gray back paper, is the most economical varieties. Applicable to non-special requirements of the use of places, the use of continuous relative humidity of not more than 65%. Because of the price reasons, many people like to use 9.5mm thick ordinary gypsum board to do the ceiling, but because the 9.5mm plain paper gypsum board is relatively thin, the intensity is not high, in the recent more rainy wet conditions prone to deformation, Recommended to do the best choice for more than 12mm ceiling gypsum board. At the same time, the use of thicker plates is also an effective means of preventing joint cracking. 2. Water-resistant paper gypsum board: green paper, green back, its core and face paper have been waterproof. According to the requirements of the national standard, water-resistant plaster board and board core must meet a certain degree of water requirements (surface water absorption of not more than 160 grams, water absorption of not more than 10%). Suitable for humid places and areas with high humidity. In the most recent rainy season, it is best to use water resistant plasterboard. Waterproof paper gypsum board for continuous relative humidity of not more than 95% of the use of places, such as bathroom, bathroom and so on. 3. Fire-resistant plaster board: red paper, gray back paper, the core of the core to increase the refractory materials and a large number of glass fiber. If you cut the gypsum board, you can see from the cross section to see a lot of glass fiber. Good quality refractory plaster board should choose a good refractory performance of alkali-free glass, the general products are used in the alkali or high alkali glass.

- Q: GRC is not commonly known as gypsum board

- No, their material is different

- Q: Gypsum board wall is 19MM thick it?

- Have. Double 9.5mm gypsum board

- Q: The main performance of gypsum board

- (1) low production energy consumption. For the production of gypsum board glued gypsum plaster, the unit production energy consumption 78% lower than cement. (2) light insulation. With gypsum board for the wall, the weight of only 1/3 of the brick wall. At the same time, due to the porous structure of gypsum board, its thermal conductivity is 0.30, compared with brick (0.43) and concrete (1.63), excellent insulation performance. (3) has excellent fire performance. As the gypsum heat to release the chemical water of its fire resistance up to 2h or more. (4) decorative function is good. Gypsum board surface smooth, between the board and the board through the cement material can be firmly bonded together to form a seamless structure, building decoration effect is good. (5) can be good construction. Gypsum board can be nailed, can be saw, sticky, the construction is very convenient, with it to do decoration, you can get rid of the traditional wet operation, greatly improve the construction efficiency. (6) comfortable living function. As the gypsum board has a unique "breathing" performance, which has the ability to adjust the indoor humidity, so that living comfort. (7) high production efficiency. Conducive to the realization of large-scale production, in a variety of building plates, gypsum board production efficiency is the highest, easy to large-scale production. (8) low investment Gypsum board production equipment and fiber gypsum board, compared to cement puff board, due to the realization of continuous mechanized production, equipment utilization is very high, less equipment investment.

- Q: On the European diamond-shaped slit gypsum board ceiling is how to do, the specific process.

- Simplify it First in accordance with the general ceiling hanging a flat top, in the flat on the top of a layer of gypsum board, double gypsum board on the seam.

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 1997 |

| Annual Output Value | Above US$100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia |

| Company Certifications | Business license;Foreign trade record certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | average |

Send your message to us

Plasterboard for Drywall Partition

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1Container m²

- Supply Capability:

- 300Containers/Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords