Fire Fighting Water Pump with Cummins Diesel Engine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fire Fighting Water Pump with Cummins Diesel Engine

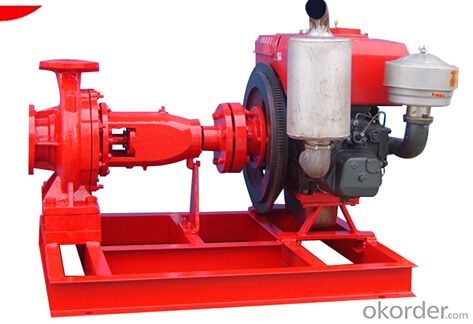

1.Structure of Fire Fighting Water Pump with Cummins Diesel Engine Description

Fire Fighting Water Pump casing is axially split, which permits removal of the complete rotor without moving either piping or motor. Pumps generating high heads have double volutes to reduce radial forces. Replaceable wear rings protect the casing at the impeller running clearances. Flange drilled to ISO, DIN, BS or ANSI.The close double suction impeller gives practically zero axial forces. Each impeller is statically and dynamically balanced according to NFPA 20 STANDARD .Vertical or horizontal, soft packing or mechanical seal, grease or oil lubrication bearing on request. NFPA 20 standard pump is available.

2.Main Features of the Fire Fighting Water Pump with Cummins Diesel Engine

•Diesel pump unit: diesel engine, water pump, cooling fan, cooling water tank, steel structure base (including fuel tank 80-120L), battery, connecting wires, exhaust muffler, control panel.

•Standard design is the pump group, the fuel tank, control panel, battery composite type.

•Can be designed according to customer requirement pump group, the fuel tank, control panel, battery, outdoor rainproof cabinet composite outdoor type.

•Can be designed according to customer requirement trailer (four or two wheels) moveable type.

3.Fire Fighting Water Pump with Cummins Diesel Engine images

4.Fire Fighting Water Pump with Cummins Diesel Engine Specification

| Capacity: | 72 to3170 m3/h |

| Size: | 100~800mm |

| Head: | 10 to 125 m |

| Power: | 30 to 800 kw |

| Speed: | 1450 or 2900 r/min |

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also

provide the pump model you are using now, price will be calculated as per the pump model, if not, we willrecommend relevant product for reference.

- Q: How can the submersible pump level meter be connected?

- Install liquid level controller, two position liquid level sensor, controller to buy manual, wiring according to wiring diagram.

- Q: You'd better point out the details.... There are 2 best ways of experience and formulaCan you say a simple point, such as multi-stage pump, when the pump is higher than the motor, 30 wire is the next mouth how to do?

- Looking forAlignment means the position of the center of rotation of the pump and motor so that they are in the same line.At least three times after the initial installation or after installation:

- Q: What are the functions of a disposable infusion pump?

- This is a very professional question, ha!I only know disposable infusion pumpsAttached: intelligent medical infusion pump and its application

- Q: What's the pump? Where can I use it?

- A pump is a machine that transports liquids or pumps liquids. Pumps are ubiquitous in life. They can be used to transport liquids such as water, oil, acid and alkali, emulsions, suspensions and liquid metals, as well as liquids, gas mixtures, and liquids containing suspended solids.

- Q: Concrete pump 125 pipe wall thickness

- Concrete pump, also called concrete pump, consists of pump body and pipe. The utility model relates to a machine for continuously conveying concrete along a pipeline by utilizing pressure, which is mainly used for building, bridges and tunnels

- Q: What kind of motor does the hydraulic pump need?

- The motor should be determined according to the work environment, such as 220V.12V.24V.72V or 380V, and then the power.Calculation of actual oil pump power:

- Q: What is the difference between centrifugal pump and rotary vane pump? What are the distinctive characteristics or principles of rotary and centrifugal? O (a _ U) O thank you!

- The vane pump can be divided into centrifugal pump, mixed flow pump and axial flow pump according to the direction of liquid flow in the impeller.Centrifugal pump is a kind of vane pump, which is the most widely used.

- Q: Is the centrifugal pump large or small?

- Centrifugal pump, the smaller the better the cavitation.1, centrifugal pump cavitation less, anti cavitation performance is better, the pump cavitation is called the necessary cavitation margin or pump inlet dynamic pressure drop, the smaller the better. Generally speaking, the pump cavitation is the need for cavitation, the pump inlet pipe said effective cavitation margin, that is, the device cavitation margin. For a given pump, at a given speed and flow rate required NPSH is called pump necessary NPSH, also called NPSH, is required to achieve the performance parameters of the pump cavitation, the internal flow and the centrifugal pump is composed of pump head itself, its physical meaning is that liquid drop in pump inlet pressure part degree, is to guarantee the pump cavitation does not occur, with surplus energy exceeds the vaporization pressure head at the inlet of the pump unit weight of liquid. The cavitation must be independent of the device parameters. It is only related to the parameters of the inlet of the pump. These parameters are determined by the geometric parameters at a given speed and flow.

- Q: Roots pump and dry pumpRecently involved in the work of the vacuum pump, don't understand this, is a ads602 vacuum pump, composed of roots pump and dry pump, is pre pumped to the 500mtorr equipment, the main pumping vacuum continues to 10mtorr, where the roots pump and dry pumps must be used? What role they play respectively. The so-called dry pump? Is refers to one kind of the pump, the pump is many dry pump? Also do not understand how the work of automatic switching system for pre pumping, the main pump, pump work alone did not connect system ah (of course there are even a butterfly) teach?

- Here the roots pump and dry pump must be used, because the roots pump is not used alone, and must be a stage vacuum pump (pre vacuum pump can be dry pump, water ring vacuum pump and rotary vane vacuum pump can be, you here with dry pump series)

- Q: How many concrete pump tube diameter

- Different pipe diameter is different, most of the 125, there are 150. Now we have the smallest pump on the market, with a pipe diameter of 100.

Send your message to us

Fire Fighting Water Pump with Cummins Diesel Engine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords