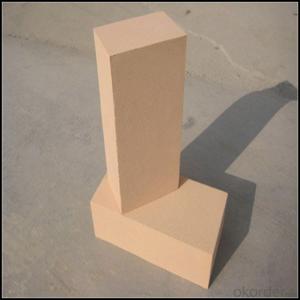

Insulating Fire Bricks for Glass Tanks - Custom Shaped Fire Clay Bricks Refractory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be used in high-temperature insulation for aerospace applications?

- Yes, insulating fire bricks can be used in high-temperature insulation for aerospace applications. Insulating fire bricks are made from lightweight refractory materials that have high insulating properties and can withstand extreme temperatures. These bricks have low thermal conductivity, which allows them to effectively reduce heat transfer and maintain the desired temperature inside aerospace components. Aerospace applications often involve high-temperature environments, such as in rocket engines, exhaust systems, and thermal protection systems. Insulating fire bricks can be used in these applications to provide thermal insulation, protecting sensitive components from excessive heat and preventing heat loss to the surroundings. Additionally, insulating fire bricks are known for their excellent resistance to thermal shock, meaning they can withstand rapid temperature changes without cracking or degrading. This property is crucial in aerospace applications where components are subjected to extreme temperature variations during launch, re-entry, or other operational phases. Moreover, insulating fire bricks have lightweight properties, which can be advantageous in aerospace applications where weight reduction is critical for fuel efficiency and overall performance. By using insulating fire bricks, aerospace engineers can achieve effective thermal insulation while minimizing the added weight to the system. Overall, insulating fire bricks offer a viable solution for high-temperature insulation in aerospace applications. Their high insulating properties, resistance to thermal shock, and lightweight nature make them suitable for protecting critical aerospace components in extreme temperature environments.

- Q: Can insulating fire bricks be used for pizza ovens?

- Yes, insulating fire bricks can be used for pizza ovens. Insulating fire bricks are designed to withstand high temperatures, making them a suitable choice for creating a well-insulated and efficient pizza oven. They help retain heat, allowing the oven to reach and maintain the desired temperature for baking delicious pizzas.

- Q: Can insulating fire bricks be used in fireplace construction?

- Yes, insulating fire bricks can be used in fireplace construction. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for lining fireplaces. They help to retain heat and prevent the transfer of heat to the surrounding structure, thus increasing the efficiency of the fireplace and reducing the risk of damage to the surrounding materials. Additionally, insulating fire bricks are lightweight and easy to handle, making them ideal for fireplace construction.

- Q: Can activated carbon be antiseptic?

- In addition to activated carbon carbon, also contains two kinds of admixtures: one is the combination of chemical elements, mainly hydrogen and oxygen, these elements are due to incomplete carbonization and the residue in the carbon, or in the process of activation, non carbon and activated carbon surface chemical foreign combination, such as the use of water vapor when activated, the surface of the active carbon is oxidized or water vapor oxidation; another kind of admixture is ash, it is part of the inorganic carbon in ash; activated carbon is easy to cause two pollution.

- Q: Can insulating fire bricks be used in high-temperature kilns for pottery?

- Yes, insulating fire bricks can be used in high-temperature kilns for pottery. These bricks are specifically designed to withstand and retain heat, making them suitable for use in kilns that reach high temperatures. They help to insulate the kiln, preventing heat loss and allowing for more efficient firing of pottery.

- Q: Can insulating fire bricks be used in the construction of ovens or kilns for pottery?

- Insulating fire bricks are capable of being used in the construction of ovens or kilns for pottery. These bricks are specifically engineered to endure high temperatures and possess exceptional insulation qualities. With their low thermal conductivity, they effectively retain heat and prevent heat loss, making them highly suitable for establishing and maintaining the elevated temperatures necessary for pottery ovens or kilns. Furthermore, these bricks exhibit excellent resistance to thermal shock, enabling them to endure sudden temperature fluctuations without fracturing or shattering. Consequently, they are a dependable option for constructing ovens or kilns that undergo frequent cycles of heating and cooling. Overall, due to their thermal insulation properties and durability, insulating fire bricks are widely favored in the construction of pottery ovens or kilns.

- Q: What material is good for indoor thermal insulation?

- Own home, if the south, hot summer and cold winter zone, with inorganic insulation mortar or polystyrene particles insulation mortar, the effect is very good;

- Q: Are insulating fire bricks resistant to molten metals?

- Yes, insulating fire bricks are generally resistant to molten metals. They are specifically designed to withstand high temperatures and provide insulation, making them suitable for applications involving molten metals.

- Q: What are the dimensions and sizes available for insulating fire bricks?

- Insulating fire bricks come in a range of dimensions and sizes to accommodate different applications and needs. The typical dimensions for these bricks are 9" x 4.5" x 2.5" and 9" x 4.5" x 3", which are appropriate for standard industrial and residential uses. However, there are also other sizes available to cater to specific requirements. For example, thinner insulating fire bricks measuring 9" x 4.5" x 1.25" or thicker ones measuring 9" x 4.5" x 4.5" can be utilized in specialized applications. These variations offer flexibility and customization options to meet specific insulation demands. It should be noted that insulating fire bricks can be cut or shaped to fit specific dimensions as necessary. This adaptability in customization allows for precise fitting and installation in various projects. Ultimately, the dimensions and sizes of insulating fire bricks will depend on the unique needs and requirements of the project. Seeking guidance from a supplier or manufacturer can aid in determining the most appropriate dimensions and sizes for your insulation needs.

- Q: Can insulating fire bricks be cut or shaped to fit specific applications?

- Insulating fire bricks possess the ability to be cut or shaped in order to accommodate specific uses. These bricks, composed of lightweight refractory materials like ceramic fibers or lightweight aggregates, maintain their structural integrity even when cut or shaped. To achieve desired dimensions or shapes for applications such as kiln lining, furnace construction, or fireplace installation, one can employ a saw, knife, or other cutting tools. Furthermore, molds or manual molding during the manufacturing process enable the shaping of insulating fire bricks. Due to their adaptability in cutting and shaping, these bricks offer great versatility and suitability for a diverse range of industrial and residential purposes.

Send your message to us

Insulating Fire Bricks for Glass Tanks - Custom Shaped Fire Clay Bricks Refractory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords