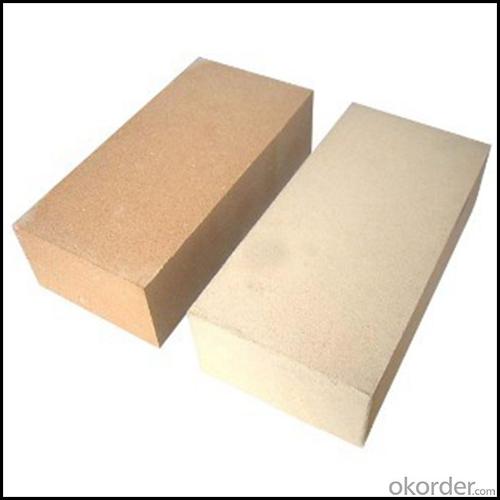

Insulating Fire Clay Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.01

- Supply Capability:

- 2400 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Acid Resistant Brick

CMAX firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

High alumina refractory brick is dense shaped refractory material. With high refractoriness and mechanical behavior under high temperature, refractory brick is the necessary material of high-temperature services, mainly used for industrial furnaces and kilns and thermal equipment.

High alumina refractory brick has wide applications, mainly used in metallurgy, construction(cement and glass), petroleum, chemical industry, electric power and machine building.

Features

1) Good thermal shock resistance

2) High-temperature endurable

3) Good thermal insulation

4) The using temperature is 1600 c

5) Phosphate high alumina bricks,iso

6) High strength

7) Low thermal conductivity

8) Widely used in cement kiln.

9) Low creeping rate

10) High pressure

11) Excellent thermal shock resistance

12) High quality fireclay clinker

Application

Iron & Steel Making Industry

Blast Furnace,Hot Blast Furnace(stove),Pellet Shaft Furnace,Hot Metal Ladle,Steel

Ladle, Tundish,Heating Furnace,Saking Pit Furnace,Heat Treatment Furnance.Refining Furnance,Reheating Furnance,Metal Mixter Furnance,Annealing Furnace,Cupola Furnace,Electric Arc Furnace,Induction Furnace,AOD Furnace,

cupola furnace,electric arc furnace,induction furnace,AOD furnace,VOD furnace,etc thermal technology equipment .

Non-Ferrous Metal Industry

Smelting furnace,refining furnace,reverberatory furnace,converter furnace

Building Materials Industy

cement kiln,glass kiln,ceramic kiln, lime kilns, kiln car,tunnel kiln

Energy & Incineration

Such as coke oven,general boiler,power generation boiler,circulating fluidized bed boiler,electric furnace,carbon roasting furnace,waste incinerators

Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: Can insulating fire bricks be used in power plants?

- Yes, insulating fire bricks can be used in power plants. Insulating fire bricks, also known as refractory bricks, are designed to withstand high temperatures and provide excellent thermal insulation. They are commonly used in various industrial applications, including power plants. Power plants generate a significant amount of heat during the combustion of fossil fuels or the process of nuclear fission. To maintain efficient operations and prevent heat loss, insulating fire bricks are used to line the walls, floors, and ceilings of furnaces, boilers, and other high-temperature areas in power plants. Insulating fire bricks have low thermal conductivity, which means they are effective at reducing heat transfer. This helps to conserve energy and improve the overall efficiency of power plants. Additionally, they have high resistance to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. Moreover, insulating fire bricks are lightweight and easy to install, making them a practical choice for power plant applications. They are also resistant to chemical corrosion, which is important in power plants where various gases and chemicals are present. In conclusion, insulating fire bricks are a suitable choice for power plants due to their ability to withstand high temperatures, provide excellent thermal insulation, and resist thermal shock and chemical corrosion. Using these bricks in power plant applications helps to enhance energy efficiency and maintain optimal operating conditions.

- Q: Are insulating fire bricks suitable for use in heat exchangers?

- Yes, insulating fire bricks are suitable for use in heat exchangers. These bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for heat transfer processes. They are commonly used in various industries, including metallurgy, glass, and ceramic manufacturing, where heat exchangers are essential for efficient heat transfer.

- Q: Are insulating fire bricks suitable for use in oil refineries?

- Insulating fire bricks do not typically suffice in oil refineries due to their inability to withstand the corrosive and abrasive nature of oil and its byproducts, despite being designed for high temperatures. Oil refineries involve a complex process of refining crude oil into various petroleum products, which often exposes materials to harsh chemicals and high temperatures. Instead, refractory bricks or castables specifically tailored to endure the corrosive and abrasive conditions present in the refining process are commonly employed. These refractory materials possess chemical resistance, high strength, thermal shock resistance, and the ability to withstand the extreme temperatures encountered during refining. Moreover, oil refineries necessitate materials that offer excellent insulation properties while also being durable and resistant to thermal stress. While insulating fire bricks possess good insulation properties, they may not possess the necessary durability and resistance to thermal stress demanded in the demanding environment of an oil refinery. Hence, it is advisable to utilize refractory bricks or castables that are designed specifically for oil refineries. These materials can provide the requisite resistance against chemicals, high temperatures, and thermal stress, ensuring the refinery operates safely and efficiently.

- Q: Do insulating fire bricks have a high insulation efficiency?

- Yes, insulating fire bricks have a high insulation efficiency. These types of bricks are specifically designed to provide excellent thermal insulation properties. They are made from lightweight materials with low thermal conductivity, such as various types of refractory clay or alumina. This composition allows them to effectively minimize heat transfer through conduction, making them highly efficient at retaining heat within a structure or appliance. Insulating fire bricks also have a high porosity, which further enhances their insulation capabilities. The presence of numerous small air pockets within the bricks reduces heat transfer by convection, as the air acts as an insulating barrier. This unique structure helps to maintain a consistent and stable temperature, whether it is in a furnace, kiln, or any other high-temperature environment. Furthermore, insulating fire bricks have high resistance to thermal shock, meaning they can withstand rapid changes in temperature without cracking or deteriorating. This property is crucial in applications where temperature fluctuations are common, as it ensures the longevity and effectiveness of the insulation. Overall, insulating fire bricks are known for their high insulation efficiency. They provide excellent thermal insulation, prevent heat loss, and contribute to energy savings. Whether used in industrial settings or residential constructions, these bricks offer reliable insulation performance and contribute to the overall energy efficiency of the system they are employed in.

- Q: Can insulating fire bricks be used in textile industry kilns?

- Insulating fire bricks are indeed applicable in the textile industry kilns. These bricks are specifically designed to endure extreme temperatures while providing exceptional insulation, rendering them appropriate for kiln usage. Within the textile industry, kilns are utilized for multiple procedures including fabric dyeing, drying, and curing. Implementing insulating fire bricks in these kilns guarantees the maintenance of a consistent and regulated temperature, resulting in efficient and uniform dispersion of heat. Furthermore, these fire bricks aid in minimizing heat loss, thereby leading to energy conservation and enhanced operational effectiveness. Hence, due to their thermal insulation properties and ability to endure high temperatures, insulating fire bricks are an ideal choice for textile industry kilns.

- Q: Can insulating fire bricks be used in solar power plants?

- Yes, insulating fire bricks can be used in solar power plants. They are commonly used in the construction of high-temperature equipment such as solar receivers, combustion chambers, and thermal energy storage systems. Insulating fire bricks help to minimize heat loss and maintain high operating temperatures, making them suitable for various applications in solar power plants.

- Q: Can insulating fire bricks be used in ladles and tundishes?

- Yes, insulating fire bricks can be used in ladles and tundishes. Insulating fire bricks are designed to withstand high temperatures, making them suitable for use in these refractory applications. They provide excellent thermal insulation, reducing heat loss and improving energy efficiency in ladles and tundishes.

- Q: Are insulating fire bricks suitable for use in the construction of lime kilns?

- Yes, insulating fire bricks are suitable for use in the construction of lime kilns. Insulating fire bricks have high thermal insulation properties, which helps in retaining heat within the kiln. This insulation is essential for maintaining high temperatures necessary for lime production. Additionally, insulating fire bricks are lightweight and durable, making them an ideal choice for lime kiln construction.

- Q: Can insulating fire bricks be used in the construction of lime production linings?

- Yes, insulating fire bricks can be used in the construction of lime production linings. Insulating fire bricks are designed to have low thermal conductivity, which makes them excellent for applications where heat insulation is required. In lime production, high temperatures are required for the calcination process. Using insulating fire bricks in the construction of lime production linings helps to reduce heat loss and improve energy efficiency. Additionally, insulating fire bricks are lightweight and easy to handle, which makes them suitable for lining various parts of lime kilns and other equipment used in the lime production process. Overall, using insulating fire bricks in lime production linings can help to optimize the production process and improve the overall performance of lime production facilities.

- Q: Can insulating fire bricks be used in aluminum furnaces?

- Indeed, aluminum furnaces can utilize insulating fire bricks. These bricks are specifically engineered to possess exceptional thermal insulation characteristics, rendering them ideal for deployment in high-temperature settings like aluminum furnaces. Their capacity to endure the intense heat generated during aluminum melting and their ability to preserve heat within the furnace contribute to enhanced energy efficiency. Moreover, insulating fire bricks offer additional benefits such as shielding against heat dissipation, mitigating the likelihood of overheating, and facilitating a more steady and regulated heating procedure.

Send your message to us

Insulating Fire Clay Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.01

- Supply Capability:

- 2400 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords