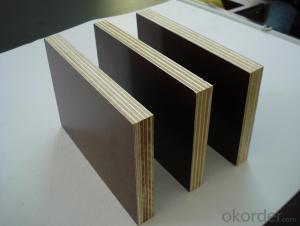

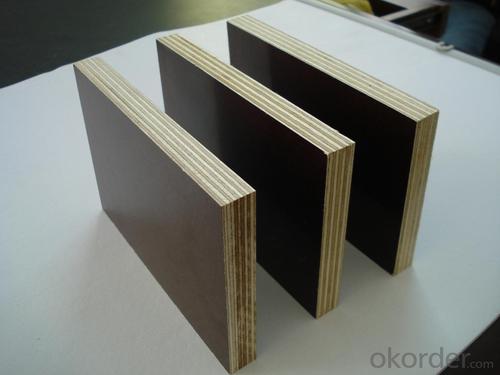

Film Faced Plywood Shuttering Plywood Construction Plywood 18mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

Item name:Black/Brown Film Faced Plywood

Size:1220*2440/1250*2500

Core: poplar/hardwood/combi/birch

Glue: WBP, melamine, phenolic

Description:

| Film faced plywood | ||||||||

| No. | Item | Data | ||||||

| 1 | Size | 1220*2440,920*1830,1230*2440,as customer's requirments | ||||||

| 2 | Thickness | 2-30mm | ||||||

| 3 | Density | 600kg/cbm and up | ||||||

| 4 | Core | Poplar,Hardwood,Combi,ect | ||||||

| 5 | F/B | Plywood : Okoume,Keruing,Bintangor,Melamine,ect Construction plywood : Black/Brown/Red film or with logo | ||||||

| 6 | Glue | MR , E1 , E2 , WBP ,ect | ||||||

| 7 | Grade | BB/BB , BB/CC , CC/CC , CC/DD , ect | ||||||

| 8 | Tolerance | 0.5mm(+/-) | ||||||

| 9 | Moisture | 8%-12% | ||||||

| 10 | Package | Seaworthy Pallet Packing wirh plastic film wrapping on the inside | ||||||

| 11 | Usage | Furniture , Construction , Packing , ect | ||||||

| 12 | Delivery Time | Within 15-30days | ||||||

| 13 | Payment | T/T 30% or L/C at sight | ||||||

| 14 | Qty | 25cbm/1*20GP 55cbm/40HQ | ||||||

| 15 | Converyance | Qty/20gp : 8 PLTS Qty/40gp : 16PLTS Qty/40hq : 18PLTS | ||||||

Features:

1. The face should be of high resistance to corrosion and moisture.

2. The face should be smooth and easy to take off from cement and easy to clean.

3. The core should be water resistant and won’t swell.

4. The core should be strong enough and won’t break.

5. The edge should be sealed and water proof.

Advantages of our film faced plywood

1. Above 18mm thickness film faced plywood , could be used 20 time at least

2. The inside each veneer is whole core

3. Each veneer is glued totally

4. Boiled for 10 hours , will not cracking

5. Twice hot press to strong joining capacity

6. Cold press again to strong joining capacity

7. 100% Dry

8. We have another glue making factory

FAQ

A. Quality :

With the skilled worker ,mature technology and ten years experience ,all our plywood are steady quality .

B. Price:

Due to the skilled worker ,mature technology and an experienced operating system , we can

quote you competitive price , so that you will have the price advantage to capture your market.

C.Service:

7*24hours , if any need, you can email or call us,we will do our best to meet your demand

D.Export experience:

Over ten years experience for exporting ,We are much familiar with

the export operation .

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides

- Q: Commonly used plywood, pallets and so on

- Is the destruction of the physical properties of the wood itself, which played a leading role in the composition of the plastic

- Q: Plywood is a common material for furniture?

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences.

- Q: Plywood is generally used in applications where the strength and stability of the material are relatively high

- It can be installed directly. It can be made of concrete frame structure and formwork.

- Q: What types of plywood can be divided into?

- Class I (NQF) - weather resistant, resistant to boiling plywood Class II (Ns) - Water resistant plywood.

- Q: Plywood in the decoration works how to use

- Commonly used plywood type plywood, penta and so on. Plywood can improve timber utilization and is a major way to save wood.

- Q: What is the difference between plywood glue E0E1?

- Urea-formaldehyde glue: moisture-proof glue / for interior decoration, furniture, can not be used for outdoor.

- Q: Decorative veneer veneer plywood features

- The product is natural and rustic, natural and noble, can create the best and elegant living room environment

- Q: The basic principle of plywood

- are symmetrical. In the same plywood, you can use a single tree and veneer thickness, you can also use different tree species and thickness of the veneer

- Q: Does plywood contain formaldehyde?

- Home plywood is a commonly used material. Plywood is the wood shavings and urea formaldehyde resin pressed together

Send your message to us

Film Faced Plywood Shuttering Plywood Construction Plywood 18mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords