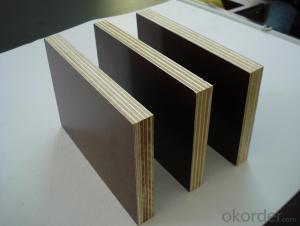

Film Faced Plywood Shuttering Plywood Combi Core Construction Plywood 18mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

Item name:Black/Brown Film Faced Plywood

Size:1220*2440/1250*2500

Core: poplar/hardwood/combi/birch

Glue: WBP, melamine, phenolic

Description:

| Product Name | Film faced plywood |

| Core | Poplar,Birch,Hardwood,Combi,etc.Or as your requirement. |

| Size | 1220x2440mm (4X8) Customized Size |

| Thickness | 18mm, Customized, etc. |

| Sruface | Black or brown film, customized |

| Color | customized |

| Glue | MELAMINE, WBP ,MR |

| Certificate | FSC CARB |

| Packing | Plywood Standard export Pallet packing----Faster and safer to load it down,with cost less labour charges.but less Qtys at the same time. |

| Bulk / Loose packing----Could load more Qtys on the same shipment,but cost more labour charges to load it down. | |

| Payment Terms | T/T or L/C at sight |

| Delivery Time | Within 15 days after receiving deposit or original L/C at sight,Urgent orders to be negotiated. |

| Port Of Shipment | Qingdao Port or Lianyungang Port |

Features:

1. The face should be of high resistance to corrosion and moisture.

2. The face should be smooth and easy to take off from cement and easy to clean.

3. The core should be water resistant and won’t swell.

4. The core should be strong enough and won’t break.

5. The edge should be sealed and water proof.

Advantages of our film faced plywood

1. Above 18mm thickness film faced plywood , could be used 20 time at least

2. The inside each veneer is whole core

3. Each veneer is glued totally

4. Boiled for 10 hours , will not cracking

5. Twice hot press to strong joining capacity

6. Cold press again to strong joining capacity

7. 100% Dry

8. We have another glue making factory

FAQ

A. Quality :

With the skilled worker ,mature technology and ten years experience ,all our plywood are steady quality .

B. Price:

Due to the skilled worker ,mature technology and an experienced operating system , we can

quote you competitive price , so that you will have the price advantage to capture your market.

C.Service:

7*24hours , if any need, you can email or call us,we will do our best to meet your demand

D.Export experience:

Over ten years experience for exporting ,We are much familiar with

the export operation .

- Q: National standards for decorative veneer veneer plywood performance requirements

- The standard on the decorative veneer veneer plywood in the appearance of quality, processing accuracy, physical and mechanical properties of the three aspects of the indicators.

- Q: Class I resistant weather plywood Class II water resistant plywood

- Hard fiber board sound absorption, waterproof performance is good, durable, easy constructio

- Q: Judging wood is the standard for plywood

- If you can identify the type of wood used by your own furniture, it will help you identify the true value of the furniture

- Q: Plywood is generally used in applications where the strength and stability of the material are relatively high

- For example: Yunshan plywood is a soft Murray plywood, it can be used for housing flooring, walls and ceiling, coated surface can also be sprayed after the coating.

- Q: What types of plywood can be divided into?

- It can withstand cold water or short-term hot water immersion, but not resistant to boiling.

- Q: A brief introduction to plywood

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: Multilayer board, also known as three plywood and plywood

- the plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like material

- Q: What is the difference between plywood glue E0E1?

- Phenolic glue: moisture, excellent resistance to boiling, weather resistance / can be used for outdoor or indoor, can withstand outdoor wind and rain.

- Q: What are the advantages and disadvantages of plywood?

- and then made of adhesive glue from the three or more layers of plate-like material

- Q: What are the plywood specifications?

- International Organization for Standardization of ordinary plywood production, from the structure, finished product moisture content, quality 3 to make the provisions:

Send your message to us

Film Faced Plywood Shuttering Plywood Combi Core Construction Plywood 18mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords