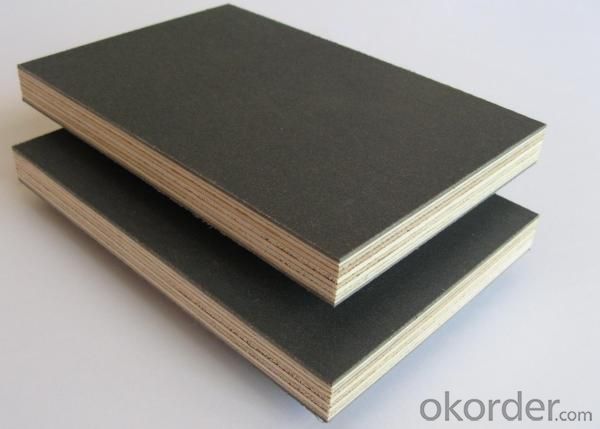

1 Inch Thick Black Film Faced Plywood Poplar Core

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³ m³

- Supply Capability:

- 2000 m³ per month m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

General Information of Black Film Faced Plywood Poplar Core

1.Size(mm): 1220x2440; 1250x2500 Thickness(mm):18; 15; 12; 20; 21

2.Glue: MR, melamine, phenolic, WBP Core: full poplar

3.Film: Dyner film or as requested Color:black

4.Application :Construction material used for concrete forming mouldings.

5.Standard ISO9001

Packaging & Delivery

1.Packaging Detail: loosing package,pallets package,all can according to customers'requirements

2.Delivery Detail: delivery within 10 days after get the deposit

Specifications of Black Film Faced Plywood Poplar Core

1.Usage:Decoration,Furniture,Construction.

2.Package:Inter packing:0.2mm plastic bag. Outer packing:Pallets are coverd with plywood or carton

3.Min order 1*20FCL or 23 cubic meter

4.Payment terms:L/C at sight,T/T 30% as deposit ,D/P.

5.Supply ability:6000 Cubic meter/month or 8000 pcs/day.

6.Main marke:Indonesia Malaysia India,Thariland,Middle East,Europe,Africa.

Advantage of Black Film Faced Plywood Poplar core

1.No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and ir will nor pollute the surface of concrete.

7.It is good to keep performance warm,ia favorable to make constrution in winter.

8.Products can be made into warping plywood

9.It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different type

- Q: The difference between the multilayer board and the plywood is as follows

- Commonly used plywood, plywood and other multi-layer board. Multilayer boards can improve wood utilization and are a major way to save wood

- Q: Now what is the market for plywood development?

- has also been greatly improved in the international market more and more competitive. China is not only a large veneer export, or the world's largest plywood producer.

- Q: What is the composition of the plywood?

- Plywood usually refers to the plywood or multi-layer board, that is, with the same thickness of two or more layers of veneer plus glue from high temperature suppression

- Q: Class I resistant weather plywood Class II water resistant plywood

- slab molding (mixing resin and additives pavement), under hot pressure, so that cellulose and Hemicellulose and lignin plasticized to form a plate.

- Q: How to use building plywood?

- in the decoration works mainly used in ceilings, wall skirts, floor linings and so on.

- Q: How do you choose plywood in plywood production?

- Another problem is the growing number of furniture produced by the panel, although these furniture, "cypress" and other grain appearance,

- Q: What types of plywood can be divided into?

- Class I (NQF) - weather resistant, resistant to boiling plywood Class II (Ns) - Water resistant plywood.

- Q: What are the defects of the plywood?

- partially intergrown knOts surrounded by the surrounding wood part of the length of its cross-section around the length of more than 1/4 to 3/4, texture Kuang hard.

- Q: What are the advantages and disadvantages of plywood?

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other.

- Q: What are the plywood specifications?

- structure. The texture of the adjacent veneer should be at right angles; the center layer is symmetrical with respect to the center layer, and the thickness of the layers is the same;

Send your message to us

1 Inch Thick Black Film Faced Plywood Poplar Core

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³ m³

- Supply Capability:

- 2000 m³ per month m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords