Shuttering Plywood Film Faced Plywood Marine Plywood Construction Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

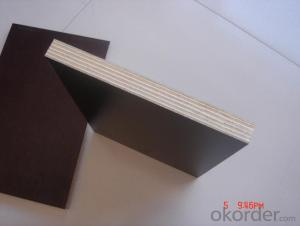

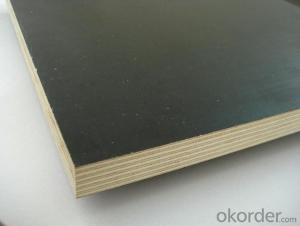

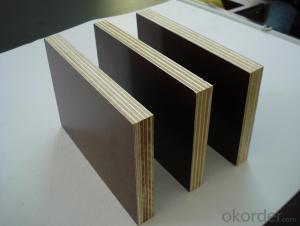

Item Name:Film Faced Plywood/Shuttering Plywood

Size:1220x1440mm,1250x2500mm

Thickness:9mm,12mm,15mm,18mm,20mm,25mm,other thickness as requested

Description

Item | Film Faced Plywood | |

Face/back |

black film or brown film,logo available | |

Core Material | poplar,hardwood,combi,finger jointg board,etc. | |

Size(mm) | 1220x2440, 1200x2400, 1250x2500, 1830x915,610x2440,etc. | |

Thickness | 9mm 12mm 15mm 18mm 21mm | |

Grade | One time hot press, two times hot press,three times hot press | |

Length(width) tolerance | 1mm | |

Thickness tolerance | +/-0.5mm or +-1mm | |

Glue | WBP(phenolic), MR, WBP MELAMINE | |

Mositure content | 8%-16% | |

Main market | Saudi Arabia,South America,Africa,Europe, India,Southeast Asia,South Korea,Thailand,etc | |

packing | Inside:pallet is wrapped with 0.2mm plastic bags; outside:pallets are covered with caton paper or plywood ,and then PVC/steel tape for strength | |

Loading quantity | 20GP | 8pallets/20M3 |

40GP | 16pallets/42M3 | |

40HQ | 18pallets/55M3 | |

Usage | Widely used for concrete formwork,shuttering work,construction,truck flooring,etc. | |

Minimum Order | 1*20GP | |

Payment | T/T or L/C at sight | |

Delivery Time |

10-30 days according to order quantity | |

Features

1) Good Raw Materials and High quality

2) More repeated using times

3) Good packing and fast shipment

4) Delivery the right products according to different level of requirement

5) High performance/price ratio

FAQ

1.What's your company property ?

More than 10 factories to meet your various needs.

2.Free samples ?

Samples are free. As for the cost of courier , we will give back to you in the payment of the trial order .

3.What's your delivery time ?

The goods will be deliveried wthin 15 days after recepit of the deposit .

Products Photos

- Q: What are the allowable quantity differences in printed packaging materials?

- Large areas of the current general offset printing, letterpress printing and other printing methods, the size of the largest paper size, the entire area of more than a full sheet size, it is limited by mechanical equipment. Screen printing can be a large area of printing, screen printing products today can reach up to 3 meters x 4 meters, or even higher significantly.

- Q: What's the printing process for PC material? Is the print content on PC or other surfaces?

- As a screen printing material, semi automatic screen printing machine for printing or anti India, in particular circumstances, is usually anti India, India will.

- Q: Carton printing process and materials

- Flexo printing and gravure printing of corrugated carton processThese two processes are the first to roll paper printing paper, and then in the automatic corrugated cardboard production line to complete the production of corrugated cardboard. Carton printing quality and molding quality are relatively high, but the investment is relatively large, it is also not suitable for small batch production.In the domestic carton industry, three conventional corrugated carton printing methods are more common, and become the mainstream of corrugated box printing. And the new printing box system, due to equipment, materials, processes, operations and other technical hot spots have not yet been fully mastered, the investment is relatively large, the promotion of the difficulty is still relatively large. But in order to improve the quality of carton enterprises, reduce the total cost of cartons, to maximize profits and increase the competitive advantage in the market, it is imperative to adopt the new printing process.

- Q: What are the materials used in screen printing?

- Divided into printed screen and printed material, screen according to different processes are divided into water-based and solvent based, printed material according to different substrate is divided into ink and ink

Send your message to us

Shuttering Plywood Film Faced Plywood Marine Plywood Construction Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords