3/4 Birch Plywood HDO Plywood Concrete Formwork 1220x2440 18mm Poplar Core Phenolic WBP Anti Slip

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

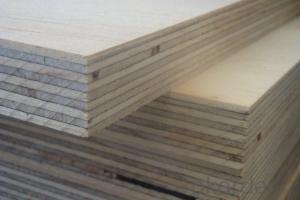

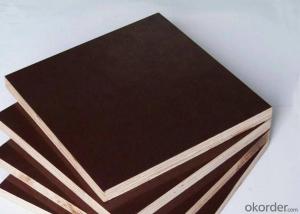

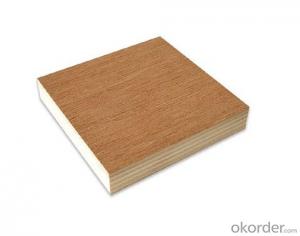

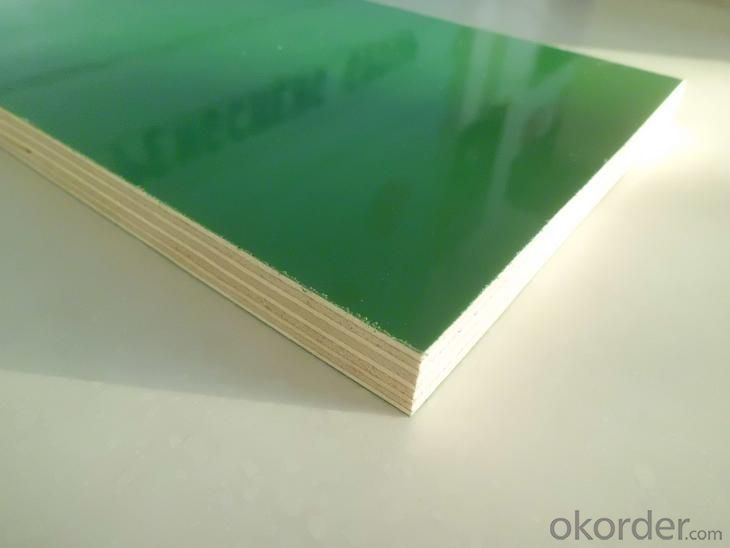

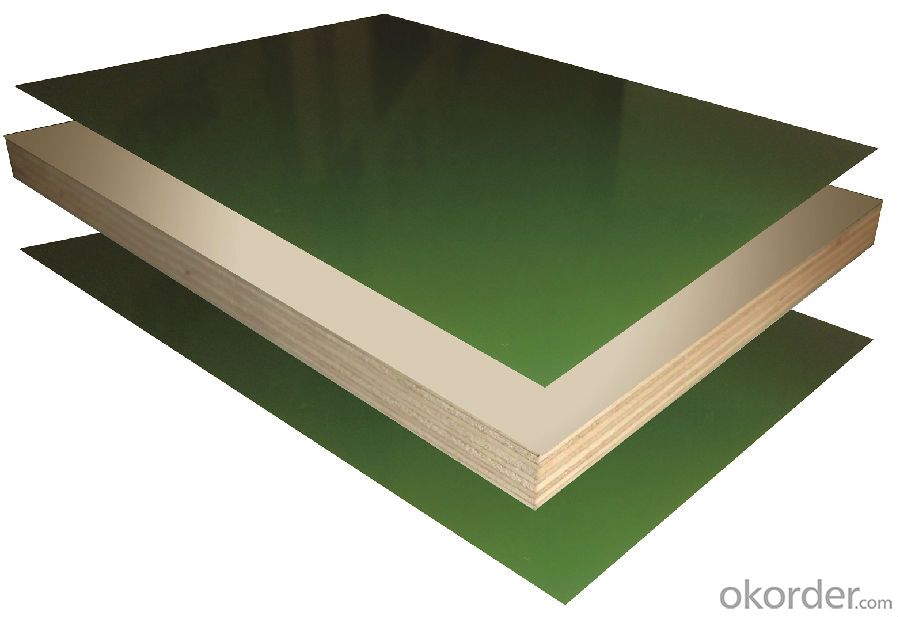

Plastic film HDO plywood concrete formwork 1220x2440 18mm poplar core phenolic WBP anti slip

What's ?

Plywood coated with Plastic, on face/back/edge.

Plastic is PP ( Polypropylene) 0.3mm /0.5mm , finish is anti-slip (wire-mesh) .

PP is super in waterproof,durable, and easy dismantle from concrete, which let the products repeatable .

Plywood is made of poplar A grade, phenolic WBP glue, 2 time hotpress, both side sanded, plastic , MC 8-14%, tolerance +/-0.2mm.

Size: 915x1830 mm (3x6) , 1220x2440mm (4x8) , 1250x2500mm ,1220x2745mm (4x9) , 1220x3050 mm (4x10).

Thickness: 12mm 15mm 18mm 21mm

Application :

for concrete forming of walls, slabs, beams & columns

Installation

as easy as film faced plywood, but no need release agent

Dismantling

Handle carefully without violent damage and scratch to ensure more usage in good condition

Cleaning

Just clean by water

Maintenance & Storage

No oil treatment, place the panel flat, away from direct sunlight and water.

Why us?

1) repeatable more than 30 times, if in formwork system, can repeat 100 times.

2) core poplar /hardwood ,phenolic WBP glue. Bending strength 51 Mpa, Modulus of Elasticity 5600 Mpa. VERY STRONG than WPC..

3) face/back, plastic ( polypropylene 0.3mm), glossy/wiremesh/matt. no chlorine.

4) edge sealed by plastic tape.

5) nice concrete finish

6) easy clean,by water, wearable and resistant chemical.

7) holes can be filled by our plastic nails.

8) plastic PP can be recycle, environmental sound.

More than 30 years experience

More than 1600 professionals

More than 9000 projects use our products.

- Q: Commonly used plywood, pallets and so on

- Is the destruction of the physical properties of the wood itself, which played a leading role in the composition of the plastic

- Q: Plywood is generally used in applications where the strength and stability of the material are relatively high

- It can be installed directly. It can be made of concrete frame structure and formwork.

- Q: What types of plywood can be divided into?

- It can withstand cold water or short-term hot water immersion, but not resistant to boiling.

- Q: What harm does the plywood factory work?

- The diagnosis of acute benzene poisoning is based on short-term inhalation of a large number of high concentrations of benzene vapor,

- Q: The Decorative veneer veneer plywood grade classification

- for example,such as some manufacturers logo level "AAA", which is corporate behavior.

- Q: Multilayer board, also known as three plywood and plywood

- the plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like material

- Q: What is the density of plywood?

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences. Commonly used plywood type plywood, penta and so on

- Q: What are the defects of the plywood?

- dead dead knots formed by the dead branches of trees, knots surrounded by the surrounding wood together, or even only part of the length of its cross-section of the length of about 1/4 or less than 1/4 , Texture hard or soft, and sometimes fall off the formation of empty.

- Q: Hard fiber board is also a density board

- Plywood boards can be full, and also allow splicing. The veneers of symmetrical layers on both sides of the center layer shall be of the same thickness,

- Q: The basic principle of plywood

- are symmetrical. In the same plywood, you can use a single tree and veneer thickness, you can also use different tree species and thickness of the veneer

Send your message to us

3/4 Birch Plywood HDO Plywood Concrete Formwork 1220x2440 18mm Poplar Core Phenolic WBP Anti Slip

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords