Fiberglass Waterproofing Membrane Fabric - Fireproof PVC Coated Fiberglass Cloth for Shipyard

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: PVC coated fiberglass fabric is finished with UL94-V0 flame retarded PVC coating. PVC coated imparts the glass fabric durable, waterproof, UV resistance etc. PVC coated glass fabric is good used for outdoor weather fire resistance cover. Colors can be green, orange, red etc.

Features: high temperature resistance,heat resistance

Application: It could be used in fields of electrical, ship building, automobile, chemical, construction and fire proof.

PRICE: USD2 per square meter

UNIT: square meter

MOQ: 500square meters

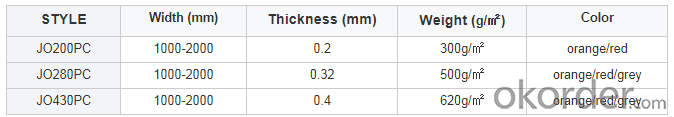

Weight: 300gsm-1100gsm

Width: 1m -2m or customized

Yarn Type: E-glass

Standing temperature: 220℃- 550℃

Product name: PVC Coated Fiberglass Fabric

Coating/Finish/Surface Treatment: PVC coated

Roll length: 50 meter or customized

Color: red or customized

Weave Type:twill woven

Alkali content: Alkali free

Processing service: cutting

Material: fiberglass PVC

Thickness: 0.2mm-1mm

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Rolls packed In cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q: Can fiberglass fabric be used for acoustic insulation?

- Indeed, acoustic insulation can be achieved by utilizing fiberglass fabric. Renowned for its remarkable sound-absorbing characteristics, fiberglass fabric proves to be an optimal substance for such purpose. By adeptly absorbing sound waves, it effectively minimizes the occurrence of echoes or reverberations resulting from their reflection off rigid surfaces. Consequently, fiberglass fabric finds extensive utilization in diverse applications like wall panels, ceiling tiles, and acoustic curtains, thereby enhancing sound quality and diminishing undesired noise levels in venues such as theaters, recording studios, and offices. Moreover, fiberglass fabric boasts attributes of being lightweight, long-lasting, and facile to install, thereby rendering it a favored option for acoustic insulation solutions.

- Q: Can fiberglass fabric be used for making insulation gaskets?

- Yes, fiberglass fabric can be used for making insulation gaskets. Fiberglass fabric is known for its excellent thermal insulation properties and is commonly used in a variety of thermal insulation applications. Its high temperature resistance and low thermal conductivity make it an ideal material for creating gaskets that can effectively seal and insulate against heat transfer. Additionally, fiberglass fabric is durable, lightweight, and flexible, making it easy to work with and suitable for various gasket designs. It is also resistant to chemicals and has good electrical insulation properties, further enhancing its suitability for insulation gaskets.

- Q: How does fiberglass fabric perform in thermal conductivity?

- Fiberglass fabric has relatively low thermal conductivity, meaning it is a poor conductor of heat. This property makes it an excellent insulating material. The structure of fiberglass fabric consists of fine glass fibers, which have low thermal conductivity due to their low density and lack of metallic components. As a result, fiberglass fabric can effectively resist the transfer of heat, keeping the temperature on one side of the fabric from affecting the other side. This makes it suitable for applications where thermal insulation is required, such as in the construction of thermal blankets, oven insulation, or as a lining for industrial equipment. Additionally, the low thermal conductivity of fiberglass fabric contributes to its fire-resistant properties, as it does not readily transfer heat to ignite or support combustion. Overall, fiberglass fabric performs well in thermal conductivity by providing insulation and fire resistance.

- Q: How does fiberglass fabric perform in chemical environments?

- Fiberglass fabric is known for its excellent performance in chemical environments. It is highly resistant to a wide range of chemicals, including acids, alkalis, solvents, and oils. The fabric's ability to withstand chemical exposure is primarily due to its composition, which consists of glass fibers that are coated or impregnated with a chemical-resistant resin. The chemical resistance of fiberglass fabric makes it an ideal choice for various applications in industries such as chemical processing, petrochemical, pharmaceutical, and food processing. It can be used in the form of curtains, gaskets, seals, and linings to protect equipment and structures from corrosive chemicals. Furthermore, fiberglass fabric's resistance to chemical exposure also extends to high temperatures. It can withstand continuous operating temperatures of up to 550°C (1022°F) without significant degradation. This property makes it suitable for applications that involve both high-temperature and chemical environments, such as thermal insulation and fire protection systems. In addition to its chemical resistance, fiberglass fabric also offers other beneficial properties. It is lightweight, durable, and has excellent mechanical strength. It is also non-flammable, providing an added layer of safety in chemical environments where fire hazards are a concern. Despite its exceptional performance in chemical environments, it is important to note that fiberglass fabric may still be susceptible to certain highly reactive chemicals or extreme conditions. Therefore, it is crucial to consult with manufacturers or experts to determine the suitability of fiberglass fabric for specific chemical environments and applications.

- Q: The pipe is too hot. What's the protection?

- Heat insulation cotton with high temperature resistance, easy combustion, low coefficient of heat conductivity, is now widely used in the insulation cotton industry is made of glass fiber and material processing, such as glass cotton, glass cotton.

- Q: The function of roof glass fiber non-woven fabric isolating layer

- To protect the waterproof layer, the main purpose is to prevent the waterproof layer from sticking together with the protective layer.

- Q: Can fiberglass fabric be used for reinforcement in agricultural tanks?

- Indeed, fiberglass fabric is a suitable option for reinforcing agricultural tanks. Renowned for its impressive strength and durability, fiberglass fabric proves to be an optimal material for reinforcing different structures, including tanks. Its resistance to corrosion, chemicals, and weathering is crucial for agricultural tanks, as they often face harsh conditions. Moreover, the lightweight nature of fiberglass fabric simplifies its handling and installation within tanks. Ultimately, the utilization of fiberglass fabric for reinforcing agricultural tanks can significantly enhance their structural integrity and lifespan.

- Q: Can fiberglass fabric be used for reinforcement in swimming pools?

- Yes, fiberglass fabric can be used for reinforcement in swimming pools. Fiberglass fabric is known for its high strength-to-weight ratio, durability, and resistance to corrosion and chemicals. These properties make it an ideal material for reinforcing swimming pools, where it can be used to reinforce the concrete or other materials used for the pool structure. The fiberglass fabric is typically applied as a layer between the layers of the pool material, such as the concrete, to provide added strength and structural integrity. It helps to prevent cracking, leaking, and other forms of damage that can occur over time. Additionally, fiberglass fabric is flexible and can be easily molded to fit the desired shape and contours of the pool, making it a versatile choice for pool reinforcement.

- Q: Can fiberglass fabric be used for making clothing?

- Clothing production with fiberglass fabric is feasible, although it is not widely adopted in the fashion industry. Fiberglass fabric is renowned for its durability, strength, and ability to resist high temperatures. It finds common usage in insulation, fireproofing, and protective gear within industrial settings. However, its qualities render it an unpopular option for clothing. The stiffness of fiberglass fabric, along with its potential to cause itchiness and discomfort against the skin, discourages its use. Moreover, the fabric lacks breathability, leading to excessive perspiration. Additionally, its inflexibility and poor draping properties make it challenging to create well-fitted and mobile garments. Hence, although technically viable, the fashion industry rarely employs fiberglass fabric for clothing production.

- Q: Can fiberglass fabric be used for making boats?

- Yes, fiberglass fabric can be used for making boats.

Send your message to us

Fiberglass Waterproofing Membrane Fabric - Fireproof PVC Coated Fiberglass Cloth for Shipyard

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords