Fiberglass Mat Tissue - E-Glass Fiberglass Woven Roving 400gsm-1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

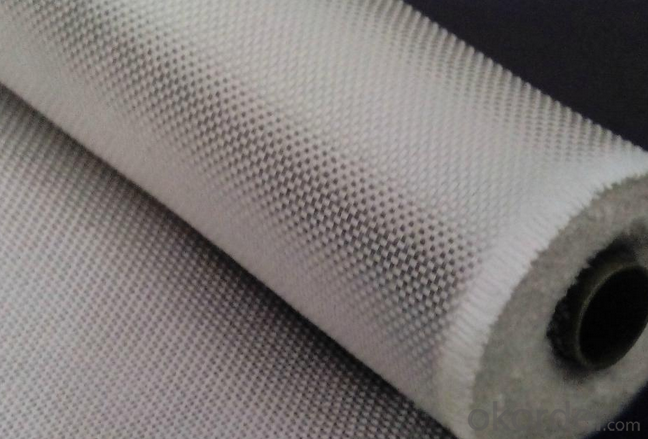

Structure of woven roving Description

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

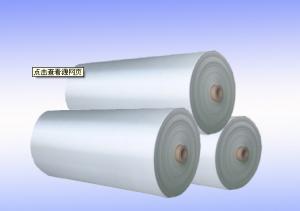

Woven roving Images

Woven roving Specification:

Normal type | EWR800 | EWR400 | EWR300 | EWR500 | EWR600 |

Thickness (mm) | 0.8 | 0.4 | 0.3 | 0.5 | 0.6 |

Density(warpxweft) (end/cm) | 1.8x1.5+/-10% | 3.6x3.2+/-10% | 4.6x4.1+/-10% | 2.2X2.0+/-10% | 2.6X2.4+/-10% |

Tex (warpxweft) | 2400x2400 | 600X600 | 300x400 | 1200x1200 | 1200X1200 |

Moisture content(%) | <0.2% | <0.2% | <0.2% | <0.2% | <0.2% |

Loss on ignition(%) | 0.4 – 0.8 | 0.4-0.8 | 0.4-0.8 | 0.4-08 | 0.4-0.8 |

Width(cm) | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 |

Weight (g/m2) | 816+/-41 | 408+/-32 | 300+/-15 | 500+/-25 | 600+/-30 |

Weight per roll(kg) | 45 | 46 | 50 | 45 | 45 |

Glass | E-glass | E-glass | E-glass | E-glass | E-glass |

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

Application of Fiberglass Woven Roving:

a) boats ,vessels ,plane

b) automotive parts ,furniture and sports facilities

c) resins system,such as polyeser,vinylester and epoxy resins

- Q: Can fiberglass mat tissue be used for electrical transformers?

- No, fiberglass mat tissue cannot be used for electrical transformers. Electrical transformers require materials with specific electrical insulating properties, such as paper or oil-impregnated materials, to ensure efficient and safe operation.

- Q: How is fiberglass mat tissue used in the production of sports equipment?

- Fiberglass mat tissue is used in the production of sports equipment as it provides strength, flexibility, and durability to the final product. It is commonly used as a reinforcement material in the manufacturing of sports equipment such as snowboards, surfboards, hockey sticks, and tennis rackets. The fiberglass mat tissue is typically layered with resin and other materials, forming a composite structure that enhances the overall performance and longevity of the sports equipment.

- Q: Can fiberglass mat tissue be used for making lightweight countertops?

- Yes, fiberglass mat tissue can be used for making lightweight countertops.

- Q: Can fiberglass mat tissue be used for ceiling insulation?

- No, fiberglass mat tissue is not typically used for ceiling insulation. It is a material commonly used in the construction of composite materials, reinforcing plastic products, and for soundproofing purposes. Ceiling insulation is typically done using materials specifically designed for thermal and acoustic insulation, such as fiberglass batts, cellulose, or foam insulation boards.

- Q: Are there any specific certifications or standards that fiberglass mat tissue must meet?

- Certifications and standards are necessary to guarantee the quality and appropriateness of fiberglass mat tissue for different purposes. The ASTM D 4601 standard is widely recognized and specifies the minimum requirements for glass fiber mats used in roofing and waterproofing systems. It covers various physical properties like weight, thickness, tensile strength, tear resistance, and water resistance. Apart from ASTM D 4601, fiberglass mat tissue may undergo testing based on its intended usage. For example, if it is used in the automotive industry, it may need to meet ISO 9001 or IATF 16949 standards, ensuring quality management systems and product consistency. Furthermore, fiberglass mat tissue used in construction or building materials should adhere to regulations set by organizations like the International Code Council (ICC), the American National Standards Institute (ANSI), or the Underwriters Laboratories (UL). These standards primarily focus on fire resistance, thermal insulation properties, and overall safety. Ultimately, the specific certifications and standards that fiberglass mat tissue must meet depend on its intended application and the industry it is used in. These standards are pivotal in ensuring the quality, performance, and safety of fiberglass mat tissue products.

- Q: Is fiberglass mat tissue compatible with vacuum infusion processes?

- Yes, fiberglass mat tissue is compatible with vacuum infusion processes. It is commonly used in vacuum infusion techniques as it allows for the distribution of resin evenly throughout the laminate, resulting in a strong and uniform composite part.

- Q: How does fiberglass mat tissue compare to fiberglass insulation batts?

- Fiberglass mat tissue and fiberglass insulation batts differ in their composition, purpose, and usage. Fiberglass mat tissue, also known as fiberglass veil or fiberglass veil mat, is a thin, non-woven fabric made from fine glass fibers. It is primarily used as a reinforcement material in composites, such as roofing materials, laminates, and automotive parts. The main purpose of fiberglass mat tissue is to add strength, durability, and resistance to cracking or tearing to the final product. It is commonly used in applications where high tensile strength and dimensional stability are required. On the other hand, fiberglass insulation batts are thick, flexible panels made from compressed fiberglass fibers. They are designed specifically for thermal insulation purposes, typically used in residential and commercial buildings. The primary function of fiberglass insulation batts is to create a thermal barrier, reducing heat transfer and improving energy efficiency. They are commonly installed in walls, attics, or crawl spaces to minimize heat loss or gain, providing better temperature control and reducing energy costs. When comparing fiberglass mat tissue to fiberglass insulation batts, it is important to note their distinct purposes and applications. Fiberglass mat tissue is not designed for thermal insulation and should not be used as a substitute for insulation batts. Conversely, fiberglass insulation batts are not suitable as a reinforcement material in composites. In terms of construction and installation, fiberglass mat tissue is typically used in conjunction with other materials, such as resins or adhesives, to form a composite structure. It can be easily cut, shaped, and molded to fit various shapes and sizes. On the other hand, fiberglass insulation batts are available in pre-cut sizes and are relatively easy to install by fitting them between framing studs or joists. Both fiberglass mat tissue and fiberglass insulation batts have their respective advantages and disadvantages, depending on the specific requirements of the project. While fiberglass mat tissue offers superior strength and dimensional stability for composites, fiberglass insulation batts excel in providing thermal insulation for buildings. Ultimately, the choice between the two will depend on the intended application and desired outcome.

- Q: Can fiberglass mat tissue be used for making lightweight automotive parts?

- Fiberglass mat tissue is indeed suitable for creating lightweight automotive parts. This material, known for its versatility, is widely used in the manufacturing process of automotive components. It boasts an impressive strength-to-weight ratio, making it perfect for producing durable and high-performing lightweight parts. Furthermore, the ease with which fiberglass mat tissue can be molded into different shapes allows for intricate and customized automotive designs. Its notable resistance to corrosion, chemicals, and temperature changes only adds to its suitability for automotive applications. In conclusion, fiberglass mat tissue is a dependable and cost-efficient option for crafting lightweight automotive parts.

- Q: How is fiberglass mat tissue different from fiberglass cloth?

- Fiberglass mat tissue and fiberglass cloth differ primarily in their construction and application. Fiberglass mat tissue is a non-woven material made of randomly oriented glass fibers bonded together with a binder. It is typically thinner and lighter than fiberglass cloth. Mat tissue is commonly used as a reinforcement layer in composite materials, providing strength and stability. On the other hand, fiberglass cloth is a woven fabric made of individual glass fibers arranged in a grid-like pattern. It is generally thicker and heavier compared to mat tissue. Fiberglass cloth is commonly used for applications requiring high strength and stiffness, such as boat building, aerospace, and automotive industries. In summary, the key differences between fiberglass mat tissue and fiberglass cloth lie in their construction, weight, and intended application. Mat tissue is a non-woven, lighter material used for reinforcement, while cloth is a woven, heavier fabric suitable for applications requiring high strength.

- Q: How does fiberglass mat tissue contribute to the strength and durability of composite materials?

- The strength and durability of composite materials are greatly enhanced by fiberglass mat tissue. To begin with, the mat tissue acts as a reinforcement element, providing added strength and rigidity to the composite structure. The fibers in the mat tissue are usually made of glass, which possesses high tensile strength and stiffness. These fibers are arranged randomly, forming a three-dimensional network that evenly distributes stress throughout the composite material. This network of fibers helps to resist cracks and fractures, thus increasing the overall strength of the composite. Additionally, the mat tissue serves as a protective barrier against delamination, a common problem in composite materials. Delamination refers to the separation of layers within the composite, which can weaken its structural integrity. By bonding the layers together and improving their adhesion, the fiberglass mat tissue prevents delamination. This enhanced adhesion reduces the chances of interface failure and improves the overall durability of the composite material. Moreover, fiberglass mat tissue contributes to the improved impact resistance of composite materials. The random fiber orientation within the mat tissue creates a crisscross pattern that enhances the composite's ability to absorb and distribute impact energy. This characteristic makes the material less susceptible to damage from external forces, such as impacts, vibrations, or mechanical stress. In conclusion, fiberglass mat tissue plays a vital role in strengthening and enhancing the durability of composite materials. Its reinforcement capabilities, delamination prevention, and improved impact resistance make it an essential component in various industries, including automotive, aerospace, construction, and marine, where the demand for strong and durable materials is critical.

Send your message to us

Fiberglass Mat Tissue - E-Glass Fiberglass Woven Roving 400gsm-1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords