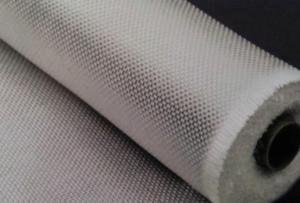

Fiberglass Mat Tissue - E-Glass Fiberglass Woven Roving, 400g, 1250mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of woven roving Description

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

Woven roving Images

Woven roving Specification: weight& thickness

Normal type | EWR800-1000 | Test Standard |

Apperance | Good | GB/T 18370-2001 |

Density(warpxweft)(end/cm) | 1.8 X 1.5 | GB/T 7689.2-2001 |

Tex (warpxweft) | 2400x2400 | ISO1889 |

Moisture content(%) | ≤0.10 | ISO3344 |

Loss on ignition(%) | 0.40-0.80 | ISO1887 |

Glass | E-glass | N/A |

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: How does fiberglass mat tissue perform in terms of UV resistance?

- Fiberglass mat tissue generally has good UV resistance. UV resistance refers to the ability of a material to withstand the harmful effects of ultraviolet radiation from the sun without degrading or deteriorating. Fiberglass mat tissue is usually manufactured using a combination of fiberglass and a binder material, which provides strength and integrity to the tissue. The fiberglass component in the mat tissue provides inherent UV resistance. Fiberglass is known for its durability and ability to resist degradation from UV exposure. It is a non-porous material that does not absorb UV radiation, making it less susceptible to damage caused by the sun's rays. Additionally, some manufacturers may apply a UV-resistant coating or treatment to the fiberglass mat tissue to enhance its UV resistance. This coating or treatment can further protect the tissue from the damaging effects of prolonged exposure to UV radiation. Overall, fiberglass mat tissue performs well in terms of UV resistance. It is a durable material that can withstand the harmful effects of UV radiation, making it suitable for applications where prolonged exposure to sunlight is expected. However, it is important to note that the specific UV resistance of fiberglass mat tissue may vary depending on the manufacturing process, quality of materials used, and any additional coatings or treatments applied.

- Q: How does the density of fiberglass mat tissue affect its performance?

- The density of fiberglass mat tissue significantly affects its performance. Fiberglass mat tissue is typically used in various applications, such as insulation, construction materials, and composite materials. The density of the fiberglass mat tissue determines its strength, durability, flexibility, and thermal insulation properties. A higher density fiberglass mat tissue generally offers better strength and durability. This is because a higher density implies more fiberglass strands are packed closely together, resulting in a denser and stronger material. It can withstand higher loads and impacts, making it suitable for applications requiring structural integrity, such as in construction or automotive industries. Moreover, the density of fiberglass mat tissue also influences its flexibility. A lower density fiberglass mat tissue tends to be more pliable and easier to shape. It can be molded into intricate shapes and contours, making it suitable for applications where flexibility is essential, such as in boat manufacturing or automotive body parts. The density also affects the thermal insulation properties of fiberglass mat tissue. Higher density fiberglass mat tissue offers better insulation against heat transfer. It effectively prevents the transfer of heat through conduction, making it ideal for insulation purposes, such as in buildings or piping systems. However, it is important to note that the density of fiberglass mat tissue should be chosen based on the specific requirements of the application. While higher density may provide better strength and durability, it also increases the weight and cost of the material. Therefore, a balance needs to be struck between the desired performance characteristics and the practicality of the specific application.

- Q: What is the typical thickness of fiberglass mat tissue?

- The typical thickness of fiberglass mat tissue ranges from 0.5 to 1.5 millimeters.

- Q: How does the density of fiberglass mat tissue impact its performance?

- The density of fiberglass mat tissue significantly affects its performance. Fiberglass mat tissue is a nonwoven material composed of randomly dispersed glass fibers held together by a binder. The density of the tissue refers to the amount of fibers present in a given volume of the material. A higher density of fiberglass mat tissue generally results in improved mechanical properties and performance. The increased density means that there are more glass fibers per unit volume, leading to enhanced strength, stiffness, and durability. This makes the material more resistant to tearing, puncturing, and abrasion, which is particularly important in applications where the tissue is exposed to harsh conditions or heavy loads. Moreover, a higher-density fiberglass mat tissue offers better thermal insulation properties. The increased fiber content allows for better heat resistance, making it suitable for applications that require thermal protection, such as insulation boards or fireproofing materials. On the other hand, a lower density of fiberglass mat tissue may provide advantages in certain applications. Lower-density tissues are generally more flexible and have better conformability, allowing them to easily adapt to irregular surfaces or complex shapes. This makes them suitable for applications where flexibility or conformability is a primary requirement, such as in automotive or aerospace industries. Overall, the density of fiberglass mat tissue plays a crucial role in determining its performance characteristics. Whether a higher or lower density is preferred depends on the specific application requirements, considering factors such as strength, stiffness, durability, thermal insulation, flexibility, and conformability.

- Q: Can fiberglass mat tissue be used for bridge construction?

- Bridge construction can indeed utilize fiberglass mat tissue. This adaptable material provides numerous benefits. Its lightweight nature and impressive strength make it ideal for bridges, especially when weight is a key consideration. Moreover, fiberglass mat tissue boasts exceptional durability and corrosion resistance, essential for maintaining bridges' longevity. Its malleability allows for flexible bridge designs, as it can be easily molded into different shapes. In addition, fiberglass mat tissue possesses excellent impact resistance and fatigue performance, guaranteeing the bridge's ability to withstand heavy loads and constant traffic. All in all, fiberglass mat tissue represents a dependable and cost-effective option for bridge construction.

- Q: Does fiberglass mat tissue require any special precautions during disposal?

- Special precautions are necessary when disposing of fiberglass mat tissue. The composition of fiberglass mat tissue can result in the release of fine particles and fibers into the air if it is handled or broken. These particles and fibers can be harmful if they are inhaled or come into contact with the skin and eyes. Therefore, it is important to take certain precautions when disposing of fiberglass mat tissue. To begin with, it is advisable to wear suitable personal protective equipment (PPE) such as gloves, goggles, and a respirator mask in order to minimize the risk of exposure. This will help to prevent the inhalation of airborne particles and fibers, as well as protect the skin and eyes from any potential irritation. Additionally, fiberglass mat tissue should be placed in sealed bags or containers during disposal to prevent loose fibers from becoming airborne during transportation. It is also recommended to label these bags or containers as "hazardous" or "fiberglass waste" so that others are aware of the potential risks involved. Furthermore, it is vital to adhere to local regulations and guidelines for the disposal of fiberglass mat tissue. Depending on the specific location, there may be specific requirements for handling and disposing of hazardous waste materials, including fiberglass. These regulations exist to safeguard public health and the environment. In conclusion, special precautions are necessary when disposing of fiberglass mat tissue in order to minimize the risk of exposure to harmful particles and fibers. Wearing appropriate protective equipment, using sealed containers, and following local regulations are all crucial steps to ensure safe disposal practices.

- Q: Can fiberglass mat tissue be used for decorative applications?

- Yes, fiberglass mat tissue can be used for decorative applications. Fiberglass mat tissue is a thin, lightweight material that is commonly used in the construction industry for reinforcing various products such as composites, plastics, and resins. However, it can also be utilized for decorative purposes. The smooth and glossy surface of fiberglass mat tissue makes it an ideal choice for adding a decorative finish to surfaces. It can be used to create unique textures, patterns, or designs on surfaces such as walls, ceilings, furniture, and even art installations. Its versatility allows it to be easily shaped, molded, or formed into different shapes, making it suitable for various creative applications. Moreover, fiberglass mat tissue is available in different colors, allowing for further customization and enhancing its decorative potential. It can be painted or coated with various finishes to achieve the desired aesthetic effect. Additionally, it is a durable material that is resistant to moisture, chemicals, and UV radiation, making it suitable for both indoor and outdoor decorative applications. Overall, fiberglass mat tissue can be an excellent choice for adding a decorative touch to various surfaces due to its smooth surface, versatility, and durability. Whether it is used for architectural design, interior decoration, or artistic installations, it offers a wide range of possibilities for creating visually appealing and unique decorative applications.

- Q: Can fiberglass mat tissue be used for composite panel manufacturing?

- Yes, fiberglass mat tissue can be used for composite panel manufacturing. It is a common material choice for reinforcing composite panels due to its high strength, durability, and compatibility with various resin systems. The fiberglass mat tissue provides structural integrity and improved strength-to-weight ratio to the composite panel, making it suitable for a wide range of applications.

- Q: What is the abrasion resistance of fiberglass mat tissue?

- The abrasion resistance of fiberglass mat tissue is high, making it suitable for applications that require durability and resistance to wear and tear.

- Q: Can fiberglass mat tissue be used for reinforcing concrete?

- Indeed, reinforcing concrete is possible with the utilization of fiberglass mat tissue. This lightweight and flexible material is frequently employed in construction endeavors to augment the sturdiness and endurance of concrete structures. By embedding it within the concrete, additional reinforcement is provided, which aids in averting the formation of cracks over time. Typically crafted from top-notch glass fibers that are interwoven to form a robust and steady substance, fiberglass mat tissue showcases exceptional tensile strength and corrosion resistance, rendering it an optimal selection for enhancing the performance of concrete. Whether employed in sidewalks, driveways, or other concrete formations, the presence of fiberglass mat tissue can substantially heighten the potency and lifespan of the concrete in question.

Send your message to us

Fiberglass Mat Tissue - E-Glass Fiberglass Woven Roving, 400g, 1250mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords