Fiberglass Mat Tissue Chopped Strand Mat for Boat Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chopped Strand Mat for Boat Building Fiberglass Mat

Introduction:

Chopped Strand Mat is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the application by hand lay-up FRP moldings, such as, various sheets and panels, boat hulls, boat tubs, cooling towers, corrosion resistant, vehicles, etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

Consistent thickness and stiffness;

Rapid impregnating and good compatibility with resin;

Superior wet through with less air trap;

Good mechanical properties and high strength of parts.

Superior acid corrosion resistance

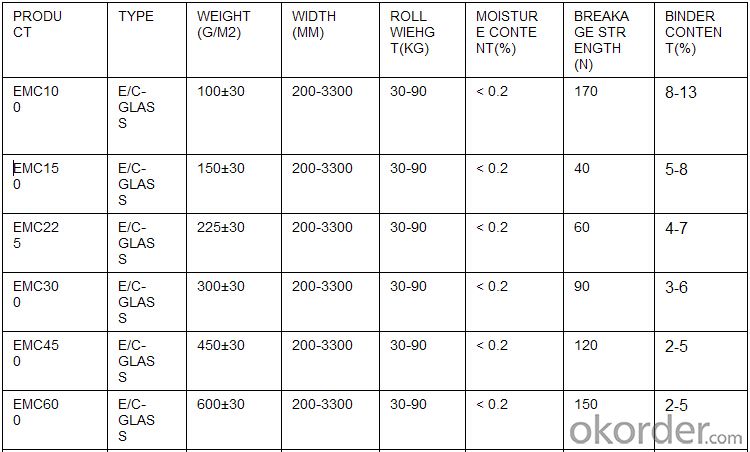

Technical Data:

Packaging:

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Can fiberglass mat tissue be used for architectural facades?

- Yes, fiberglass mat tissue can be used for architectural facades. Fiberglass mat tissue is a lightweight and flexible material that is commonly used in various construction applications, including architectural facades. It offers several advantages such as high strength, durability, weather resistance, and fire resistance. Additionally, fiberglass mat tissue can be easily molded into different shapes and sizes, making it suitable for architectural designs that require unique and intricate facades. Its versatility and aesthetic appeal make it a popular choice among architects and designers for creating visually appealing and functional facades.

- Q: How is fiberglass mat tissue used in the production of agricultural equipment?

- Fiberglass mat tissue, a type of thin fiberglass material, plays a crucial role in the production of agricultural equipment. It is primarily used as a reinforcement material in the manufacturing process of agricultural equipment, such as tractors, harvesters, and sprayers. One of the main applications of fiberglass mat tissue in agricultural equipment production is in the construction of structural components. The tissue is often used to reinforce the body panels and chassis, providing strength and durability to the equipment. This reinforcement helps to enhance the overall structural integrity and load-bearing capacity of the agricultural machinery, making it more reliable and capable of withstanding the demanding conditions of agricultural operations. Moreover, fiberglass mat tissue is also used in the production of agricultural equipment for its corrosion resistance properties. Agricultural machinery is often exposed to harsh environments, including chemicals, fertilizers, and the elements. By incorporating fiberglass mat tissue into the manufacturing process, the equipment becomes more resistant to corrosion, extending its lifespan and reducing maintenance costs. Additionally, fiberglass mat tissue is utilized in the production of agricultural equipment to improve its insulation and soundproofing capabilities. By incorporating layers of fiberglass mat tissue between the panels and components, the equipment becomes better insulated against temperature fluctuations, reducing energy loss and improving efficiency. Moreover, the tissue helps to dampen noise and vibration, creating a quieter and more comfortable working environment for operators. In summary, fiberglass mat tissue is a critical component in the production of agricultural equipment. Its reinforcement, corrosion resistance, insulation, and soundproofing properties contribute to the overall performance, durability, and efficiency of agricultural machinery, making it an indispensable material in this industry.

- Q: What are the different reinforcement orientations available for fiberglass mat tissue?

- Fiberglass mat tissue offers several reinforcement orientations, each intended for specific purposes in different applications. One common orientation is unidirectional reinforcement, where fibers align in one direction. This orientation provides great strength and stiffness in that alignment, making it suitable for applications requiring resistance to tension or bending forces in a single direction. Another orientation is bidirectional reinforcement, where fibers align in two perpendicular directions. This orientation provides equal strength and stiffness in both directions, making it ideal for applications needing resistance to tension and compression forces. Structural components like panels, pipes, and tanks commonly employ bidirectional reinforcement. A third orientation is randomly oriented reinforcement, where fibers distribute randomly. This orientation offers isotropic properties, meaning it provides similar strength and stiffness in all directions. Random reinforcement is often used in applications requiring uniform strength and flexibility, like automotive parts, boat hulls, and sporting goods. Furthermore, hybrid reinforcement orientations are available, combining different fibers or orientations to meet specific performance requirements. These hybrids offer a combination of strength, stiffness, flexibility, and other desired properties, making them suitable for a wide range of applications. Overall, the choice of reinforcement orientation for fiberglass mat tissue depends on the application's specific requirements, including desired mechanical properties, forces to be resisted, and other performance considerations.

- Q: Can fiberglass mat tissue be used for making insulation blankets?

- Yes, fiberglass mat tissue can be used for making insulation blankets.

- Q: Is fiberglass mat tissue suitable for insulation in hospitals?

- Yes, fiberglass mat tissue is suitable for insulation in hospitals. It provides excellent thermal insulation properties and is fire-resistant, which is crucial for ensuring the safety of patients and staff in healthcare environments. Additionally, fiberglass mat tissue is a durable and cost-effective option for insulation, making it a practical choice for hospitals.

- Q: Can fiberglass mat tissue be used for insulation boards?

- Insulation boards can indeed utilize fiberglass mat tissue as a viable option. This lightweight and flexible material consists of delicate glass fibers melded together with a resin. Its outstanding thermal insulation qualities make it an optimal selection for insulation boards. The mat tissue is effortlessly customizable, capable of conforming to various shapes and sizes, thereby facilitating insulation of walls, roofs, floors, and other areas within a structure. Notably, it possesses resistance against moisture, mold, and mildew, ensuring enduring insulation performance. Moreover, fiberglass mat tissue exhibits fire-resistant properties, further bolstering its suitability for insulation applications. In summary, fiberglass mat tissue proves to be an adaptable and efficient material for insulation boards.

- Q: Does anyone know the hardness value of the heat conductive gasket? Does it contain the hardness of the carrier (glass fiber)?

- SHORE hardness is only for the hardness of the heat conductive gasket itself

- Q: How does fiberglass mat tissue compare to polystyrene insulation?

- Fiberglass mat tissue and polystyrene insulation are two different materials with distinct properties and uses. Fiberglass mat tissue is a woven or non-woven fabric made from glass fibers. It is commonly used as a reinforcement material in various applications such as roofing, pipes, and automotive parts. Fiberglass mat tissue provides excellent strength, durability, and resistance to moisture and chemicals. On the other hand, polystyrene insulation refers to rigid foam boards or expanded polystyrene (EPS) beads used for thermal insulation purposes. Polystyrene insulation offers high thermal resistance, making it an effective material for insulating buildings and reducing energy consumption. Comparing the two, fiberglass mat tissue is primarily used for reinforcement and structural purposes, whereas polystyrene insulation is specifically designed for thermal insulation. The choice between them depends on the specific requirements of the application, such as the need for structural strength or thermal efficiency.

- Q: Is fiberglass mat tissue suitable for soundproofing?

- Fiberglass mat tissue can be suitable for soundproofing purposes, but its effectiveness may vary depending on the specific requirements and desired level of soundproofing. Fiberglass mat tissue is a lightweight and flexible material that can effectively absorb and dampen sound waves. It has good acoustic properties and can help reduce noise transmission, making it a viable option for soundproofing applications. However, it is important to note that fiberglass mat tissue alone may not provide sufficient soundproofing, especially in high-noise environments. For optimal results, it is recommended to combine it with other soundproofing materials such as acoustic foam panels or mass-loaded vinyl to enhance its soundproofing capabilities. Additionally, the thickness and density of the fiberglass mat tissue can also affect its sound absorption properties. Thicker and denser mats are generally more effective at attenuating sound waves, but they may also be less flexible and harder to install. In conclusion, while fiberglass mat tissue can contribute to soundproofing efforts, its suitability depends on the specific requirements, desired level of soundproofing, and the use of additional materials. Consulting with a soundproofing expert or conducting thorough research on the specific application is recommended to determine the most appropriate solution for effective soundproofing.

- Q: What are the potential health hazards associated with working with fiberglass mat tissue?

- Potential health hazards associated with working with fiberglass mat tissue include skin irritation, respiratory issues such as coughing and wheezing, eye irritation, and allergic reactions. Long-term exposure to fiberglass fibers can also lead to a condition called fiberglass lung, which is characterized by chronic coughing, chest tightness, and difficulty breathing. It is important to use proper protective equipment, such as gloves, goggles, and a respirator, when working with fiberglass mat tissue to minimize these risks.

Send your message to us

Fiberglass Mat Tissue Chopped Strand Mat for Boat Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords