Fiberglass Mat Tissue C Glass Woven Roving for FRP Application

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 17600 m²

- Supply Capability:

- 17600kg Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

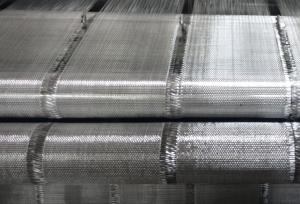

Glass woven rovings are bidirectional fabric made by direct rovings in plain weave pattern.

Compatible with unsaturated polyester,vinylresin ,epoxy resin.

Applicable for hand lay-up, winding and compress molding process,Suitable for manufacturing tank,boat,automobile parts and other FRP products.

Consistent thickness and excellent surface treatment.

Rapid impregnating and good compatibility with resin.

Uniform tension,high dimensional stability and making handing easy.

Good mechanical properties and high strength of parts.

Technical Data Sheet

Style | Yarn(Tex) | Density(ends/10cm) | (g/m2) | Width(cm) | Tensile strength(N/50mm) | ||

Warp | Weft | Warp | Weft | ||||

EWR200 | 200 | 50 | 50 | 200±16 | 90/100 | ≥1300 | ≥1100 |

ERW400 | 600 | 35 | 32 | 400±32 | 100/127 | ≥2500 | ≥2200 |

EWR570 | 1150 | 26 | 24 | 570±45 | 100/127 | ≥3600 | ≥3300 |

EWR600 | 1200 | 26 | 24 | 600±48 | 100/127 | ≥4000 | ≥3850 |

EWR800 | 2400 | 18 | 16 | 800±64 | 100/127 | ≥4600 | ≥4400 |

CWR135 | 150 | 50 | 40 | 135±10 | 90/100 | ≥750 | ≥600 |

CWR180 | 200 | 50 | 50 | 200±16 | 90/100 | ≥1150 | ≥1000 |

CWR290 | 450 | 35 | 30 | 290±22 | 90/100 | ≥1500 | ≥1400 |

CWR310 | 500 | 35 | 28 | 310±24 | 90/100 | ≥1600 | ≥1500 |

CWR330 | 500 | 35 | 31 | 3300±26 | 90/100 | ≥1700 | ≥1600 |

CWR350 | 500 | 35 | 35 | 350±28 | 90/100 | ≥1800 | ≥1700 |

CWR400 | 500 | 40 | 40 | 400±32 | 90/100 | ≥2000 | ≥1900 |

CWR600 | 1200 | 26 | 24 | 600±48 | 100/127 | ≥2750 | ≥2600 |

CWR800 | 2400 | 18 | 16 | 800±61 | 100/127 | ≥3000 | ≥2900 |

FAQ

Package and Storage:Eech roll is packed by polyester bag,and then put into a cardboard box or plastic wowen bag.The weight of each roll is between 20 to 85 Kg, The rolls are to be horizontally placed and could be in bulk or on pallet.Optimum storage conditions are between the temperature of 5~35℃ and with the humidity between 35%~65%.The product should be used within 12 months from the time of delivery and remain in theiroriginal packaging until just prior to use.

- Q: Can fiberglass mat tissue be used for pipe insulation?

- No, fiberglass mat tissue is not typically used for pipe insulation. Fiberglass mat tissue is a thin material that is commonly used for reinforcing purposes in various industries. It is not designed to provide thermal insulation or to prevent heat loss in pipes. For pipe insulation, materials such as foam, mineral wool, or fiberglass pipe insulation are more commonly used. These materials are specifically designed to provide thermal insulation and protect pipes from heat loss, condensation, and freezing.

- Q: Can fiberglass mat tissue be used for making fiberglass molds?

- Yes, fiberglass mat tissue can be used for making fiberglass molds. It is often used as a reinforcement layer to provide strength and stability to the mold, allowing it to withstand the pressures and forces exerted during the molding process.

- Q: What is the flexibility of fiberglass mat tissue at low temperatures?

- The flexibility of fiberglass mat tissue at low temperatures is generally maintained, as fiberglass has low thermal expansion and contraction properties, allowing it to retain its flexibility even in cold conditions.

- Q: Can fiberglass mat tissue be used for insulation in chemical storage tanks?

- Yes, fiberglass mat tissue can be used for insulation in chemical storage tanks. Fiberglass is known for its excellent insulation properties, making it a suitable material for insulating tanks that store chemicals. The fiberglass mat tissue is typically made from fine glass fibers that are woven together to create a strong and durable material. This mat tissue can be applied to the inner walls of the tank to provide insulation and prevent heat transfer. Additionally, fiberglass is corrosion-resistant and can withstand the harsh chemicals often stored in these tanks, making it an ideal choice for insulation in chemical storage tanks.

- Q: How does fiberglass mat tissue perform in terms of heat insulation?

- Fiberglass mat tissue performs well in terms of heat insulation due to its low thermal conductivity, which helps to minimize heat transfer. It acts as a barrier, preventing the escape of heat and keeping the surrounding environment insulated.

- Q: Is fiberglass mat tissue suitable for insulation in laboratories?

- Yes, fiberglass mat tissue is suitable for insulation in laboratories. It offers excellent thermal insulation properties, is resistant to high temperatures, and provides effective sound insulation. Additionally, it is non-combustible and chemically inert, making it ideal for laboratory environments where safety and performance are crucial.

- Q: Does fiberglass mat tissue require any special precautions during transportation?

- Yes, fiberglass mat tissue does require special precautions during transportation. Fiberglass mat tissue is a delicate material that can easily get damaged if not handled properly. Therefore, it is important to take certain precautions to ensure its safe transportation. Firstly, the fiberglass mat tissue should be packed in a sturdy and durable packaging material that can protect it from any external impacts or vibrations. This can be achieved by using heavy-duty cardboard boxes or wooden crates that provide adequate cushioning and support. Additionally, it is crucial to label the packaging clearly as "Fragile" or "Handle with Care" to alert the handlers about the delicate nature of the product. This will help prevent any mishandling or rough treatment during transportation. Furthermore, fiberglass mat tissue should be stored and transported in an upright position to minimize the risk of any bending or folding that could potentially damage the material. It is also important to avoid stacking heavy objects on top of the fiberglass mat tissue to prevent any unnecessary pressure or crushing. Lastly, it is advisable to use secure and reliable transportation services that have experience in handling delicate materials like fiberglass mat tissue. This ensures that the product is transported with utmost care and attention, reducing the chances of any damage during transit. By following these special precautions, the risk of damage to the fiberglass mat tissue during transportation can be significantly minimized, ensuring that it reaches its destination in perfect condition.

- Q: How is fiberglass mat tissue used in the aerospace industry?

- Due to its exceptional properties and versatility, fiberglass mat tissue finds extensive use in the aerospace industry. It plays a crucial role in the manufacturing and maintenance of aircraft, serving various purposes. One of the primary applications of fiberglass mat tissue in the aerospace industry lies in its incorporation into composite materials. These materials, formed by combining two or more substances, are widely employed in aircraft construction to reduce weight while ensuring structural integrity. In composite laminates, fiberglass mat tissue acts as a reinforcement material, providing strength, stiffness, and dimensional stability. Consequently, it is suitable for various components such as wings, fuselage, and tail sections. The high tensile strength of fiberglass mat tissue guarantees that the composite structure can withstand the demanding conditions faced in the aerospace industry. Moreover, aircraft repair and maintenance extensively utilize fiberglass mat tissue. This material is commonly employed in the process of composite patching, which involves the restoration of damaged or worn-out composite components. By impregnating the fiberglass mat tissue with resin and applying it to the affected area, strength is restored and structural integrity is regained. This technique is widely employed for repairing aircraft components like fairings, radomes, and other composite parts, ensuring their safe and reliable operation. Additionally, fiberglass mat tissue finds application in the insulation of aircraft. It is used as a thermal and acoustic insulator in critical areas of the aircraft, including the interior cabin. By reducing heat transfer and preventing condensation, fiberglass mat tissue helps maintain a comfortable environment for passengers and crew. Furthermore, its sound-absorbing properties minimize noise levels inside the aircraft, ultimately enhancing the overall travel experience. In summary, fiberglass mat tissue is an essential material in the aerospace industry. Its exceptional properties, including high tensile strength, dimensional stability, and thermal/acoustic insulation capabilities, make it an ideal choice for a wide range of applications. From composite structures to aircraft repair and maintenance, fiberglass mat tissue proves indispensable in ensuring the efficiency and safety of aerospace operations.

- Q: Is fiberglass mat tissue suitable for insulation in food processing facilities?

- Fiberglass mat tissue is not a suitable choice for insulation in food processing facilities due to its intended use as a reinforcement in composites, such as roofing and construction materials, rather than meeting the specific requirements of food processing environments. In order to ensure the safety and compliance of food processing facilities, it is necessary to use insulation materials that are safe, durable, and in accordance with strict health and safety regulations. Fiberglass mat tissue lacks these essential characteristics and may potentially endanger food safety. To address this issue, it is recommended to utilize insulation materials that are specifically designed for food processing facilities. These materials should be non-toxic, resistant to moisture, mold, and bacteria, and capable of withstanding high temperatures and frequent cleaning and sanitization procedures. Some examples of appropriate insulation materials for food processing facilities include closed-cell foam, mineral wool, and polyisocyanurate (PIR) foam. These materials have undergone extensive testing and have been proven to meet the necessary standards and regulations for use in food processing environments. Given the importance of prioritizing the safety and hygiene of food processing facilities, it is advisable to seek guidance from experts or insulation specialists who possess the knowledge and expertise to recommend the most suitable and compliant insulation options for these facilities.

- Q: Can fiberglass mat tissue be used for automotive parts?

- Automotive parts can indeed utilize fiberglass mat tissue. This adaptable material offers strength, rigidity, and durability. Within the automotive industry, it finds widespread use in a range of applications including reinforcing panels, bumpers, hoods, and body parts. Its lightweight composition makes it ideal for reducing vehicle weight and enhancing fuel efficiency. Moreover, it boasts resistance against corrosion, chemicals, and extreme temperatures, rendering it a dependable choice for automotive parts. Its flexibility further enables manufacturers to easily mold and shape it, facilitating the creation of intricate designs and desired aesthetics. Considering its strength, durability, lightweight nature, and versatility, fiberglass mat tissue stands as an exceptional option for automotive parts.

Send your message to us

Fiberglass Mat Tissue C Glass Woven Roving for FRP Application

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 17600 m²

- Supply Capability:

- 17600kg Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords