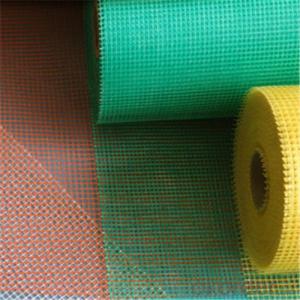

Fiberglass Lampshade Fabric YX-GF(SL) 105 Glass Fiber Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | Brand Name: | Model Number: | |||

| Application: | Surface Treatment: | Width: | |||

| Weave Type: | Yarn Type: | Alkali Content: | |||

| Standing Temperature: | colour: | high temperature resistance: | |||

| breadth: | thickness: |

Packaging & Delivery

| Packaging Detail: | carton or plastic woven bags |

| Delivery Detail: | 10 work days |

Specifications

silica gel coated glass fiber cloth

thicknes:0.8mm-3.0mm

breadth:1000mm

high temperature resistance:350~450C

- Q: Is fiberglass fabric resistant to chemicals used in oil and gas industry?

- Yes, fiberglass fabric is generally resistant to the chemicals used in the oil and gas industry. Fiberglass is known for its excellent chemical resistance, making it suitable for various industrial applications, including oil and gas. It can withstand exposure to a wide range of chemicals, including acids, alkalis, solvents, and hydrocarbons commonly found in the oil and gas industry. This resistance is due to the inert nature of the fiberglass material, which does not react or degrade when exposed to these chemicals. Additionally, the fabric's non-porous structure prevents the absorption of chemicals, further enhancing its resistance. Overall, fiberglass fabric is an ideal choice for applications requiring chemical resistance in the oil and gas industry. However, it is always recommended to consult with manufacturers or suppliers to ensure the specific type of fiberglass fabric being used is suitable for the intended chemical environment.

- Q: How does fiberglass fabric perform in thermal conductivity?

- Fiberglass fabric is known for its low thermal conductivity, meaning it is a poor conductor of heat. This property allows it to provide excellent insulation and heat resistance, making it suitable for various applications where thermal protection is required.

- Q: How is fiberglass fabric used in the production of insulation ropes?

- Due to its exceptional thermal insulation properties and durability, fiberglass fabric is widely utilized in the manufacturing of insulation ropes. The fabric undergoes initial weaving or knitting using thin strands of fiberglass, resulting in a resilient and flexible structure. During the manufacturing process, it is customary to apply a heat-resistant silicone or acrylic coating to the fiberglass fabric. This coating serves to enhance its resistance to high temperatures and bolster its capacity to withstand wear and tear. Additionally, it functions as a preventive measure against the fabric becoming undone or frayed. To create the insulation ropes, the coated fiberglass fabric is skillfully braided or twisted, yielding a tightly woven rope-like formation. This construction technique allows the rope to effectively trap air and establish a thermal barrier, effectively impeding heat transfer and minimizing energy loss. The fiberglass fabric employed in insulation ropes exhibits remarkable resistance to fire, chemicals, and moisture, rendering it suitable for a range of industrial applications. It finds frequent use in HVAC systems, boilers, ovens, and other high-temperature environments where insulation is of utmost importance. In summary, fiberglass fabric assumes a critical role in the production of insulation ropes, offering outstanding thermal insulation, durability, and resistance to various environmental factors. These qualities make it an ideal material for insulating applications.

- Q: How is fiberglass fabric used in the chemical industry?

- Fiberglass fabric finds numerous applications in the chemical industry due to its exceptional properties and versatility. One of the primary uses of fiberglass fabric is in corrosion-resistant applications. Fiberglass fabric is highly resistant to chemical attack, making it an ideal material for lining tanks, pipes, and other equipment that handle corrosive chemicals. It can withstand exposure to a wide range of chemicals, including acids, alkalis, solvents, and various organic compounds. Furthermore, fiberglass fabric is utilized in the construction of storage tanks for hazardous chemicals. These tanks are often reinforced with multiple layers of fiberglass fabric to provide structural integrity and prevent leakage. The fabric's high tensile strength and excellent dimensional stability make it an excellent choice for such applications. In addition, fiberglass fabric is used in manufacturing chemical filters and membranes. These filters and membranes are designed to separate and purify different chemical compounds. Fiberglass fabric's high porosity allows for efficient flow rates while retaining solid particles and impurities. Its resistance to chemical degradation ensures long-term durability and reliability. Moreover, fiberglass fabric is employed as a protective barrier in the chemical industry. It is used to create curtains, blankets, and covers that shield workers, equipment, and surroundings from potential chemical spills or splashes. These protective barriers act as a reliable shield against hazardous substances, preventing accidents and minimizing the risk of chemical exposure. Overall, fiberglass fabric plays a vital role in the chemical industry by providing corrosion resistance, structural reinforcement, filtration capabilities, and protection against chemical hazards. Its unique combination of properties makes it an indispensable material in various chemical processes, ensuring safety, efficiency, and longevity in chemical operations.

- Q: Is fiberglass fabric suitable for making car covers?

- Yes, fiberglass fabric is suitable for making car covers. It is known for its durability, strength, and resistance to heat and chemicals, making it an excellent choice for protecting vehicles from various environmental elements such as UV rays, rain, and dust. Additionally, its lightweight nature allows for easy handling and storage of the car cover.

- Q: Can fiberglass fabric be used for making shower curtains?

- Absolutely! When it comes to making shower curtains, fiberglass fabric is a stellar choice. Renowned for its durability, water resistance, and effortless upkeep, it's an ideal material. This fabric resists mildew and mold, which are frequent concerns in bathrooms, and can withstand the moisture and humidity found in shower areas. What's more, fiberglass fabric is a breeze to clean and doesn't absorb water, preventing saturation or unpleasant odors. All in all, opting for fiberglass fabric to create shower curtains ensures a lasting and hygienic solution for any bathroom.

- Q: Is fiberglass fabric easy to cut and sew?

- Yes, fiberglass fabric is relatively easy to cut and sew. Its thin and flexible nature allows for clean cuts and smooth sewing, making it manageable for various projects. However, it is important to take necessary precautions such as wearing appropriate protective gear and using sharp tools to ensure safety during cutting and sewing.

- Q: Can fiberglass fabrics be used for waterproofing?

- Yes, fiberglass fabrics can be used for waterproofing. They possess excellent water resistance properties and are commonly used in applications such as waterproof clothing, tents, and boat covers. The tightly woven structure of fiberglass fabrics helps to prevent water penetration, making them an effective material for waterproofing purposes.

- Q: Is fiberglass fabric resistant to chemicals in agricultural applications?

- Generally, fiberglass fabric exhibits resistance to chemicals in agricultural applications. Its exceptional chemical resistance is well-known and makes it suitable for a variety of industrial and agricultural uses. It can withstand exposure to a wide array of chemicals, such as acids, alkalis, solvents, and commonly used agricultural pesticides. This chemical resistance guarantees the durability and functionality of fiberglass fabric in agricultural settings, even when it comes into direct contact with potentially corrosive substances. Moreover, fiberglass fabric also possesses resistance to UV radiation, moisture, and extreme temperatures, thereby further enhancing its suitability for agricultural applications.

- Q: How do you do fiberglass fabric on latex paint?

- Latex paint made of diatom mud, made of fiber cloth, did not try

Send your message to us

Fiberglass Lampshade Fabric YX-GF(SL) 105 Glass Fiber Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords