Geocells Market Fiberglass Geogrid Mesh 25.4*25.4 for Softbed Foundation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

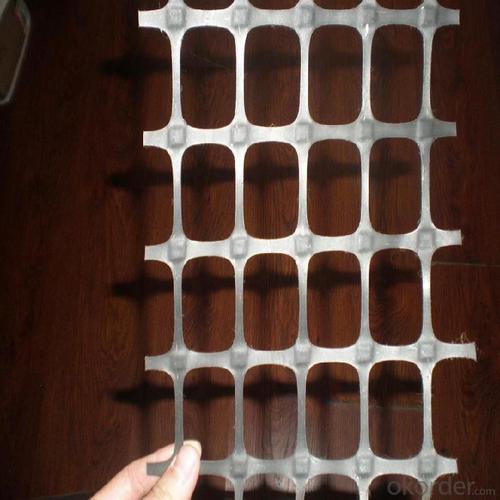

Structure of Fiberglass Geogrid

Fiberglass Geogrid is to select high quality enhanced non-alkali fiberglass yarn,and it uses foreign advanced warp knitting woven to become the base materials.Using the warp knitting oriented structure to make full use of the fabric yam strength and improve its mechanical properties ,so it makes good tensile strength ,tearing strength and resistance to creep properties of modified asphalt,and through high quality coating is handled and become planar finely materials.

Main Features of the Fiberglass Geogrid

fiberglass geogrids

Corrosion resistance, no long-term creep, long life span.

Good physical and chemical stability and good thermal stability.

Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

Tensile strength:MD/CD:30 ~ 150kn/m.

Light weight, high tensile, corrosion resistance

Road maintenance and reinforcement

Packaging & Delivery

| Packaging Details: | PP bags or PE film. Or Packed as customers' requests. |

| Delivery Detail: | 10-20days after the contract is effective |

Biaxial Geogrid Images

Biaxial Geogrid Specification

Roadbed reinforcement of road and railway,crack prevention,increase of roadbed strength;

- Reinforcement and stabilization of riverside,embankment and side slope;

Dyke reinforcement on soft ground for stress evenness,sedimentation adjustment,increase of stability and loading capacity of fundus;

Reinforcement of the surface of road and bridge

Preventing and controlling the cracking caused by new and old combination and uneven settlement.

Road extension.

Reinforcement of soft soil foundation and overall strength of roadbed

| Specification | EGA30-30 | EGA50-50 | EGA80-80 | EGA100-100 | EGA120-120 | ||

| Mesh size(mm) | 25.4×25.4or12.5×12.5 | ||||||

| Breaking strength≥(KN/m) | Warpdirection | 30 | 50 | 80 | 100 | 120 | |

| Across warp | 30 | 50 | 80 | 100 | 120 | ||

| Elongation at break≤(%) | Warp direction | 3 | |||||

| Across warp | 3 | ||||||

| Elasticity modulus(GPA) | 67 | ||||||

| Thermal tolerance() | -100~280 | ||||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Biaxial Plastic Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: What are the advantages of using geogrids?

- Geogrids offer several advantages, including improved soil stabilization, increased load-bearing capacity, and enhanced drainage capabilities. These materials reinforce the soil structure, preventing erosion and promoting long-term stability. Geogrids also minimize the need for excessive excavation and reduce construction costs, making them an economical solution. Additionally, they can be easily installed, making them a convenient choice for various projects.

- Q: Can geogrids be used in mining applications?

- Yes, geogrids can be used in mining applications. Geogrids are a type of geosynthetic material that are commonly used in civil engineering and construction projects to reinforce soil and provide stability. In mining applications, geogrids can be used to strengthen and stabilize the ground, prevent soil erosion, and provide support to mining infrastructure such as haul roads and tailings dams. By improving the structural integrity of the ground, geogrids can contribute to safer and more efficient mining operations.

- Q: How do geogrids improve the stability of levees?

- Geogrids improve the stability of levees by providing reinforcement and increased tensile strength. These engineered materials are placed within the levee structure, creating a network of interconnected elements that distribute and withstand the forces exerted on the levee. This helps to prevent slope failure, soil erosion, and potential breaches, ultimately enhancing the overall stability and safety of the levee system.

- Q: What are the different materials used to manufacture geogrids?

- Geogrids are manufactured using various materials such as polyester, polypropylene, high-density polyethylene (HDPE), and fiberglass. These materials offer different strengths, durability, and chemical resistances, allowing geogrids to be customized for various applications in civil engineering and construction projects.

- Q: Geogrid price? Solution!

- Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid.

- Q: How do geogrids prevent lateral spreading of soil?

- Geogrids prevent lateral spreading of soil by providing reinforcement and increased stability to the soil structure. When placed within the soil, geogrids distribute the tensile forces and restrict the movement of soil particles, reducing the potential for lateral movement. The interlocking of the geogrids with the soil creates a stronger composite material, preventing the soil from spreading laterally and maintaining its integrity.

- Q: Can geogrids be used in erosion control on riverbanks?

- Yes, geogrids can be used in erosion control on riverbanks. Geogrids are commonly used in such applications to stabilize the soil and prevent erosion by reinforcing the bank's structure and retaining the soil in place.

- Q: How do geogrids reduce settlement in embankments?

- Geogrids reduce settlement in embankments by providing additional reinforcement and stability to the soil. They act as a high-strength reinforcement material, distributing the applied loads more evenly across the embankment. This helps to minimize the consolidation and settlement of the underlying soil, resulting in reduced settlement and improved overall performance of the embankment structure.

- Q: How is the installation of geogrids carried out?

- The installation of geogrids typically involves preparing the subgrade by removing any loose soil or debris, compacting the surface, and then laying the geogrid on top. The geogrid is then secured in place using stakes or anchors, and additional layers of soil or aggregate are placed on top to cover the geogrid. This helps to reinforce the soil, increase its stability, and prevent erosion or soil movement.

- Q: Can geogrids be used in underground mining applications?

- Yes, geogrids can be used in underground mining applications. Geogrids are commonly used in mining operations for reinforcement and stabilization of soil or rock structures. They provide support to prevent soil or rock movement, enhance load distribution, and improve overall stability in underground mining operations.

Send your message to us

Geocells Market Fiberglass Geogrid Mesh 25.4*25.4 for Softbed Foundation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords