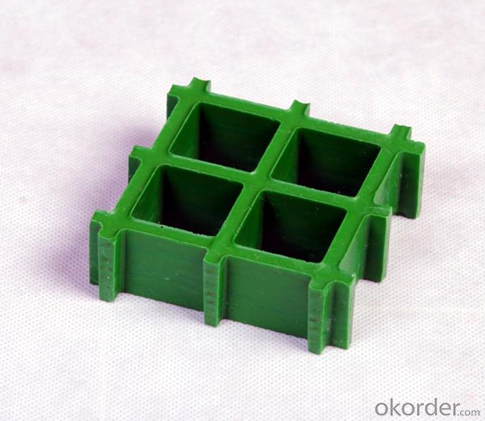

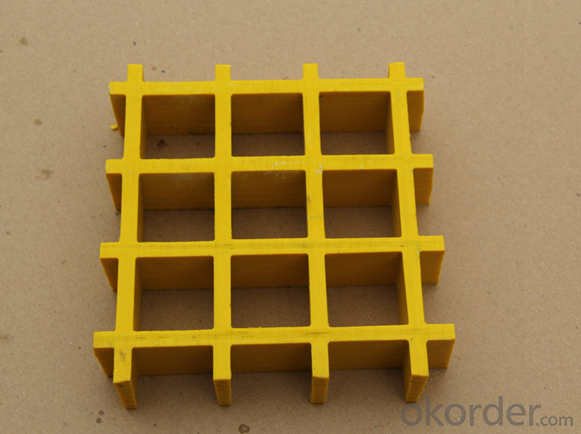

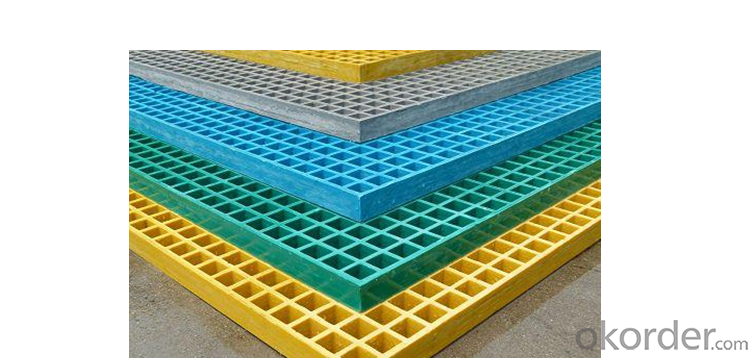

FRP Pultrusion Profiles - Molded Gratings / GRP Gratings / FRP Gratings with Modern Shapes / All Kinds of Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

- Aging Resistance

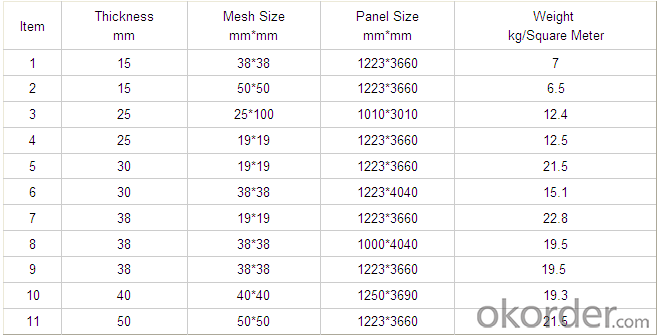

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

- easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

- All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

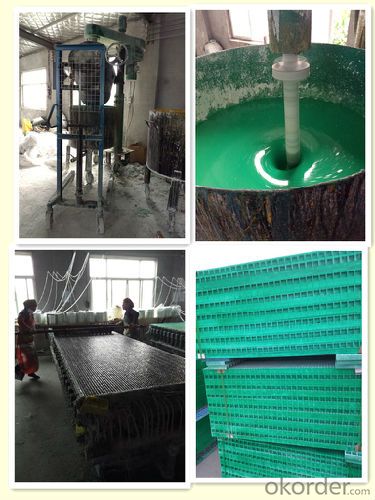

PROCESS

FACTORY

- Q: Can FRP pultrusion profiles be used in the water treatment industry?

- Yes, FRP pultrusion profiles can be used in the water treatment industry. FRP (Fiber Reinforced Plastic) offers excellent corrosion resistance and durability, making it suitable for various applications in water treatment plants. FRP pultrusion profiles can be used in the construction of water tanks, pipes, pumps, and other equipment, providing a lightweight and high-strength alternative to traditional materials like steel. Additionally, FRP profiles are non-conductive and have low thermal conductivity, making them ideal for applications involving chemicals and extreme temperature variations commonly found in water treatment processes.

- Q: Can FRP pultrusion profiles be used in the construction of agricultural structures?

- FRP pultrusion profiles have the capability to be utilized in the construction of agricultural structures. They possess various advantages that make them appropriate for agricultural applications. To begin with, FRP pultrusion profiles are both lightweight and strong, making them well-suited for the creation of agricultural structures such as greenhouses, barns, and storage facilities. Their high strength-to-weight ratio enables easy installation and reduces the overall weight of the structure, thus minimizing the need for heavy machinery during construction. Furthermore, FRP pultrusion profiles have the benefit of being corrosion-resistant. This is a critical characteristic for agricultural structures that are exposed to diverse environmental elements like moisture, chemicals, and fertilizers. Unlike traditional materials like wood or steel, FRP does not rot, rust, or corrode, ensuring the longevity and durability of the agricultural structure. Additionally, FRP pultrusion profiles possess excellent electrical insulation properties. This is particularly advantageous in agricultural applications where electrical equipment, such as lighting systems or ventilation controls, are commonly employed. The non-conductive nature of FRP eliminates the risk of electrical shocks or short circuits. Moreover, FRP pultrusion profiles are highly customizable and can be tailored to meet specific requirements. This adaptability allows for the creation of structures that are customized to the unique needs of agricultural operations, such as load-bearing capacity, dimensional accuracy, and thermal insulation. Furthermore, FRP pultrusion profiles are non-magnetic, which makes them suitable for use in agricultural structures where magnetic interference can disrupt sensitive equipment or affect crop growth. In conclusion, the utilization of FRP pultrusion profiles in the construction of agricultural structures provides numerous benefits, including lightweight construction, corrosion resistance, electrical insulation, customization options, and non-magnetic properties. These advantages establish FRP pultrusion profiles as a viable and practical choice for agricultural applications.

- Q: How do FRP pultrusion profiles perform in electrical grounding systems?

- FRP (Fiber Reinforced Polymer) pultrusion profiles have shown promising performance in electrical grounding systems. These profiles are made of a combination of fibers, such as glass or carbon, and a polymer resin matrix, which provides high strength, durability, and corrosion resistance. One of the key advantages of FRP pultrusion profiles in electrical grounding systems is their excellent electrical insulation properties. Unlike metals, which conduct electricity, FRP profiles have a very high resistance to electrical current, making them ideal for applications where electrical isolation is crucial. This property helps prevent the risk of electrical shock hazards and reduces the potential for short circuits. Additionally, FRP pultrusion profiles offer high mechanical strength while being lightweight. This makes them easy to handle and install, reducing labor costs and time. The profiles are also resistant to UV radiation, chemicals, and moisture, ensuring long-term performance and durability in various environmental conditions. Another benefit of FRP pultrusion profiles is their resistance to corrosion. Unlike metals, which can rust and deteriorate over time, FRP profiles are immune to corrosion, making them ideal for use in harsh or corrosive environments. This corrosion resistance ensures the longevity and reliability of the electrical grounding system. Furthermore, FRP pultrusion profiles are non-magnetic, which is advantageous in applications where magnetic interference needs to be minimized or eliminated. This characteristic prevents any interference with sensitive electrical equipment and ensures accurate electrical measurements. Overall, FRP pultrusion profiles offer a range of advantages in electrical grounding systems. Their excellent electrical insulation properties, high mechanical strength, corrosion resistance, lightweight nature, and non-magnetic characteristics make them a reliable and efficient choice for ensuring safe and reliable electrical grounding.

- Q: How do FRP pultrusion profiles compare to traditional materials, such as steel or aluminum?

- FRP pultrusion profiles offer several advantages compared to traditional materials like steel or aluminum. Firstly, FRP profiles are significantly lighter in weight, making them easier to handle and transport. This characteristic is especially beneficial in applications where weight reduction is crucial, such as in aerospace or automotive industries. Moreover, FRP pultrusion profiles are highly corrosion resistant, unlike steel which is prone to rusting and aluminum which can corrode in certain environments. This corrosion resistance makes FRP profiles ideal for applications in harsh or corrosive environments, such as chemical plants or coastal areas. Another advantage of FRP pultrusion profiles is their excellent strength-to-weight ratio. Despite being lightweight, FRP profiles exhibit high strength and stiffness, often surpassing steel and aluminum. This strength allows for the design of structurally efficient components, reducing material and installation costs. Furthermore, FRP profiles are electrically non-conductive, offering inherent insulation properties. This feature makes them suitable for applications where electrical conductivity is undesirable, such as electrical cabinets or offshore platforms. In terms of thermal conductivity, FRP pultrusion profiles have low thermal conductivity compared to metals. This characteristic improves insulation and reduces heat transfer, making them suitable for applications requiring temperature control or insulation, such as refrigeration or thermal insulation systems. Lastly, FRP pultrusion profiles are highly customizable. They can be easily molded into complex shapes and sizes, allowing for design flexibility and meeting specific project requirements. This versatility makes FRP profiles suitable for a wide range of applications, including construction, infrastructure, and industrial sectors. Overall, FRP pultrusion profiles offer numerous advantages over traditional materials like steel or aluminum, including lighter weight, corrosion resistance, high strength-to-weight ratio, electrical insulation, low thermal conductivity, and design flexibility. These benefits make FRP profiles a preferred choice in various industries, providing cost-effective and reliable solutions.

- Q: Can FRP pultrusion profiles be used in the construction of water treatment plants?

- Water treatment plants can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess several advantages that render them suitable for this purpose. To begin with, FRP pultrusion profiles exhibit resistance to corrosion. Water treatment plants encounter various corrosive substances, such as chemicals and moisture. Traditional materials like steel and concrete can degrade over time due to corrosion, resulting in maintenance complications and potential structural failures. Nevertheless, FRP pultrusion profiles possess a high resistance to corrosion, ensuring prolonged durability and reduced maintenance expenses. Furthermore, FRP pultrusion profiles are lightweight and possess high strength-to-weight ratios. This characteristic facilitates easy handling and transportation while maintaining structural integrity. Water treatment plants often necessitate structural components that can endure heavy loads and support equipment. FRP pultrusion profiles supply the required strength without adding excessive weight, making them an ideal choice for such applications. Additionally, FRP pultrusion profiles are non-conductive and possess exceptional electrical insulation properties. This attribute proves critical in water treatment plants where electrical apparatus and wiring are present. The non-conductive nature of FRP aids in preventing electrical hazards and guarantees safe operation. Moreover, FRP pultrusion profiles can be customized to fulfill specific design requirements. They can be manufactured in various shapes and sizes, allowing for design and construction flexibility. This adaptability renders FRP pultrusion profiles appropriate for a wide array of applications within water treatment plants, including structural supports, walkways, handrails, and equipment enclosures. In conclusion, FRP pultrusion profiles represent an exceptional option for the construction of water treatment plants due to their corrosion resistance, lightweight yet robust nature, electrical insulation properties, and customization possibilities. They provide long-lasting durability, reduced maintenance costs, and enhanced safety, thereby constituting a reliable and efficient solution for this critical infrastructure.

- Q: Can FRP pultrusion profiles be used in the construction of amusement park rides?

- Yes, FRP pultrusion profiles can be used in the construction of amusement park rides. FRP (Fiber Reinforced Polymer) pultrusion profiles offer high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various applications in amusement park rides. These profiles can be used for structural components, such as supports, frames, and beams, as well as for aesthetic elements like facades or decorative structures. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements, making them a versatile choice for constructing amusement park rides.

- Q: Can FRP pultrusion profiles be customized or tailored to specific project requirements?

- Indeed, FRP (Fiber Reinforced Polymer) pultrusion profiles have the capability to be customized or tailored according to the specific demands of a project. The process of pultrusion, which is employed in the manufacturing, enables the creation of continuous fiber-reinforced composite profiles while providing a considerable amount of design flexibility. By adjusting the design and manufacturing parameters, the dimensions, shapes, and mechanical properties required by a project can be accommodated. The customization procedure commences with a comprehension of the project's needs and specifications. This involves identifying the desired profile dimensions, cross-sectional shape, and mechanical properties such as strength, stiffness, and durability. Based on these requirements, engineers and manufacturers can devise a personalized solution. The customization of FRP pultrusion profiles can be accomplished through various methods. Firstly, the selection of reinforcement materials, such as fiberglass, carbon fiber, or aramid fiber, can be made based on the desired mechanical characteristics. The orientation and volume fraction of the fibers can also be adjusted to optimize the strength and stiffness of the profile. Additionally, the resin matrix utilized in the pultrusion process can be customized to enhance specific properties like fire resistance, chemical resistance, or UV resistance. To meet the project's requirements, different resin systems including polyester, vinyl ester, or epoxy can be utilized. Furthermore, during the manufacturing process, the pultrusion method allows for the incorporation of additional features. This includes the addition of inserts, fastener holes, grooves, or other structural details to the profile. These modifications can be tailored to the specific project requirements, ensuring compatibility with the overall design and assembly. In conclusion, FRP pultrusion profiles offer a significant level of customization and tailoring to cater to the specific demands of a project. This versatility has made them a favored choice in various industries such as construction, infrastructure, aerospace, and automotive, where lightweight, durable, and corrosion-resistant materials are essential.

- Q: Can FRP pultrusion profiles be used in telecommunications towers?

- Telecommunications towers can indeed utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess several advantageous features that render them suitable for this particular application. Firstly, FRP profiles possess a lightweight yet robust nature, facilitating effortless installation and reducing the overall structural weight of telecommunications towers. This characteristic is crucial as it aids in minimizing the burden imposed on the tower structure. Secondly, FRP pultrusion profiles exhibit exceptional resistance to corrosion, making them ideally suited for outdoor applications such as telecommunications towers that are constantly exposed to diverse environmental conditions. Unlike conventional materials like steel or wood, FRP profiles do not succumb to rust, rot, or deterioration when subjected to moisture, UV radiation, or chemicals typically encountered in outdoor environments. Additionally, FRP pultrusion profiles offer excellent electrical insulation properties, a critical aspect for telecommunications towers. These profiles are non-conductive, thereby reducing the likelihood of electrical interference or short circuits that might disrupt the tower's communication systems. Moreover, FRP pultrusion profiles can be produced in various shapes and sizes, thereby enabling customization and meeting the specific design requirements of telecommunications towers. This versatility facilitates seamless integration and compatibility with other components of the tower. Overall, the combination of lightweight composition, high strength, corrosion resistance, electrical insulation, and customization options renders FRP pultrusion profiles an advantageous and viable selection for utilization in telecommunications towers.

- Q: How to install GRP mark pile

- The first said the difference is not the same as the first material (FRP pultrusion is out of the square or triangle pipe by processing printing or engraving machine engraving to cover finished concrete (concrete) is the direct brush word OK)

- Q: Can FRP pultrusion profiles be used in the transportation and logistics industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the transportation and logistics industry. FRP pultrusion profiles offer several advantages that make them suitable for various applications in this industry. Firstly, FRP pultrusion profiles are lightweight yet extremely strong and durable. This makes them ideal for use in transportation vehicles, such as trucks, trailers, and containers, where reducing weight is crucial for improving fuel efficiency and reducing emissions. Despite their lightweight nature, FRP pultrusion profiles can withstand heavy loads and harsh environmental conditions, ensuring their reliability and longevity. Secondly, FRP pultrusion profiles are highly corrosion-resistant. Unlike traditional materials, such as steel or aluminum, FRP does not rust or corrode when exposed to moisture or chemicals. This makes FRP profiles suitable for use in transportation and logistics applications that involve exposure to corrosive substances, such as saltwater, chemicals, or acidic environments. By using FRP pultrusion profiles, companies can reduce maintenance costs associated with corrosion and prolong the lifespan of their equipment. Additionally, FRP pultrusion profiles offer design flexibility. They can be manufactured in various shapes, sizes, and configurations to meet the specific requirements of transportation and logistics applications. Whether it is for structural components, platforms, flooring, or supports, FRP profiles can be customized to fit different needs, ensuring optimal performance and functionality. Moreover, FRP pultrusion profiles have excellent electrical and thermal insulation properties. This makes them suitable for applications where electrical conductivity needs to be minimized or thermal insulation is required. In the transportation and logistics industry, this can be beneficial for applications such as insulation for refrigerated containers or electrical insulation for specialized vehicles. In summary, FRP pultrusion profiles are well-suited for the transportation and logistics industry. Their lightweight, strong, durable, corrosion-resistant, and customizable nature, along with their electrical and thermal insulation properties, make them a reliable choice for various applications in this sector.

Send your message to us

FRP Pultrusion Profiles - Molded Gratings / GRP Gratings / FRP Gratings with Modern Shapes / All Kinds of Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords