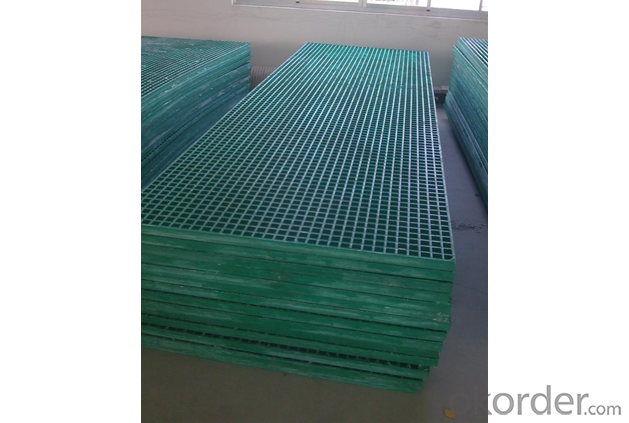

FRP Pultrusion Profiles - Fiberglass FRP Phenolic Molded and Pultruded Gratings with High Quality/Modern Shape

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

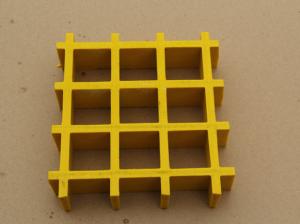

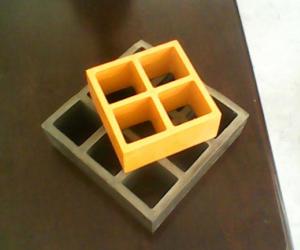

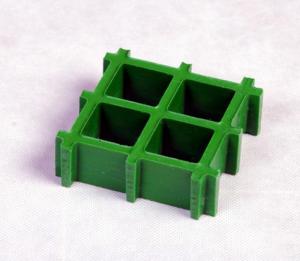

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Light Weight & High Strength

Safety & Anti-slip

Electrical Insulating

Aging Resistance

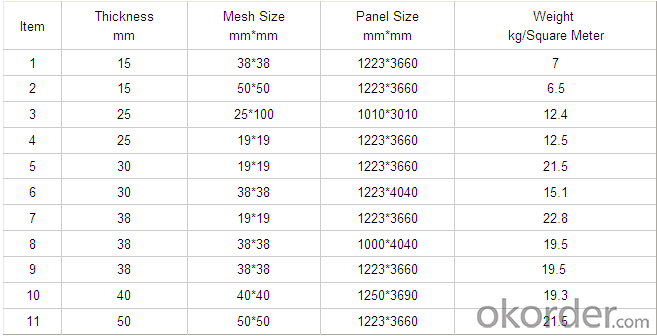

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

- easy installation

Application

- In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

2. How is the package?

Usually, we arrange the standard out-package for exporting.

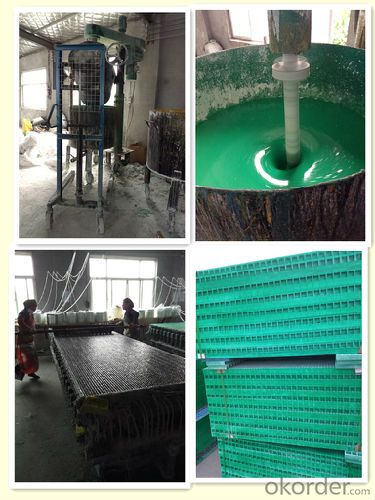

FACTORY

- Q: Can FRP pultrusion profiles be used in chemical storage tanks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in chemical storage tanks. FRP pultrusion profiles are known for their excellent corrosion resistance, making them suitable for storing a wide range of chemicals. They are also lightweight, strong, and have a high strength-to-weight ratio, which makes them an ideal choice for constructing durable and long-lasting chemical storage tanks. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in tank design and construction. Overall, FRP pultrusion profiles are a reliable and cost-effective option for chemical storage tanks due to their corrosion resistance, strength, and customization capabilities.

- Q: The difference between polyurethane pultruded profiles and glass reinforced plastic profiles

- The polyurethane pultrusion section is a product formed by mixing the polyol and a reactive isocyanate easily and quickly.Isocyanate is to optimize the molding characteristics and selection, these characteristics are: low viscosity (good impregnation fiber), gel time (easy to start and stop), rapid polymerization (improve molding speed), good surface finish, cost competitive.

- Q: Can FRP pultrusion profiles be used in the construction of train or subway platforms?

- Yes, FRP pultrusion profiles can be used in the construction of train or subway platforms. FRP (Fiber Reinforced Polymer) offers excellent strength, durability, and corrosion resistance, making it suitable for high-traffic areas like train or subway platforms. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements, making them a versatile choice for platform construction.

- Q: What are the load-bearing capabilities of FRP pultrusion profiles?

- FRP (Fiber Reinforced Polymer) pultrusion profiles have excellent load-bearing capabilities. The load-bearing capacity of FRP pultrusion profiles is determined by several factors such as the type and arrangement of fibers, resin properties, and the overall design of the profile. FRP pultrusion profiles are commonly used in various industries due to their high strength-to-weight ratio. The reinforcing fibers, typically made of materials such as fiberglass or carbon fiber, provide the profile with exceptional tensile and flexural strength. These fibers are embedded in a resin matrix, which further enhances the load-bearing capabilities of the profile. The load-bearing capacity of FRP pultrusion profiles can be tailored to meet specific requirements by adjusting the fiber type, orientation, and resin properties during the manufacturing process. This allows for a wide range of design possibilities and enables engineers to optimize the profiles for different applications. Furthermore, FRP pultrusion profiles exhibit excellent resistance to corrosion, making them suitable for use in harsh environments. Unlike traditional materials such as steel or wood, FRP profiles do not rust or rot, ensuring long-term durability and structural integrity. Overall, the load-bearing capabilities of FRP pultrusion profiles are highly impressive, making them a reliable choice for various load-bearing applications such as structural supports, bridges, platforms, and industrial equipment.

- Q: Can FRP pultrusion profiles be used in the production of electrical busbars?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the production of electrical busbars. FRP pultrusion profiles are known for their excellent electrical insulation properties, high strength-to-weight ratio, and corrosion resistance. These characteristics make them suitable for various electrical applications, including busbars. FRP pultrusion profiles offer superior electrical insulation compared to traditional metal busbars, reducing the risk of electrical shock and short circuits. Additionally, their high strength-to-weight ratio allows for the production of lightweight busbars that can handle high electrical currents without sacrificing structural integrity. Furthermore, FRP pultrusion profiles have excellent resistance to corrosion and chemicals, making them ideal for use in harsh environments, such as chemical plants or outdoor installations. They are not susceptible to rust or degradation, ensuring the longevity and reliability of the electrical busbars. Overall, FRP pultrusion profiles provide a cost-effective and efficient solution for the production of electrical busbars, offering enhanced electrical insulation, strength, and corrosion resistance compared to traditional metal alternatives.

- Q: Are FRP pultrusion profiles resistant to sulfuric acid?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to sulfuric acid. The corrosion resistance of FRP profiles is one of their key advantages compared to traditional materials like steel or concrete. Sulfuric acid is a highly corrosive substance, but FRP pultrusion profiles can withstand its effects due to the inherent properties of the composite materials used in their construction. The corrosion resistance of FRP profiles is mainly attributed to the resin matrix that encapsulates the reinforcing fibers. Most commonly used resins in pultrusion, such as polyester, vinyl ester, or epoxy, have excellent chemical resistance properties, including resistance to sulfuric acid. However, it is important to note that the resistance of FRP pultrusion profiles to sulfuric acid can vary depending on several factors. The concentration and temperature of the acid, as well as the specific resin formulation used in the profile, can influence the overall resistance. In highly concentrated or elevated temperature environments, it is advisable to consult with the manufacturer or supplier to ensure the specific FRP profile meets the required resistance level. In general, FRP pultrusion profiles offer a high level of resistance to sulfuric acid, making them suitable for various applications in industries where this corrosive substance may be present, such as chemical processing, wastewater treatment, or mining.

- Q: Are FRP pultrusion profiles resistant to acids?

- FRP pultrusion profiles, known as Fiber Reinforced Polymer pultrusion profiles, exhibit a notable resistance to acids. This corrosion resistance is a significant advantage that sets FRP apart from traditional materials like steel or wood. The composite materials employed in FRP pultrusion profiles display exceptional resistance to a broad spectrum of acids, including organic and inorganic varieties. The ability of FRP pultrusion profiles to resist corrosion can be attributed to the chemical composition of the composite materials. The reinforcing fibers, such as glass or carbon fibers, exhibit a high resistance to acid attacks. Furthermore, the polymer matrix used in FRP acts as a protective barrier, preventing acid penetration. It is important to acknowledge, however, that the resistance of FRP pultrusion profiles to acids may vary depending on the specific type of acid and its concentration. While FRP generally offers resistance against most acids, certain aggressive acids or highly concentrated solutions may cause some degradation over time. For optimal performance and durability, it is advisable to consult the manufacturer or supplier of FRP pultrusion profiles for precise information regarding their resistance to acids. They can provide valuable guidance on the suitability of FRP profiles for applications involving acids and recommend additional protective measures, such as coatings or liners, if necessary.

- Q: Can FRP pultrusion profiles be customized according to specific requirements?

- FRP pultrusion profiles can be tailored to specific requirements, offering a wide range of customization options. Pultrusion is a manufacturing process that involves pulling continuous fibers through a liquid resin bath and then curing the resin in a heated die to achieve the desired shape. This process allows for flexibility in design and customization. Customization possibilities for FRP pultrusion profiles include dimensions, shapes, colors, and surface finishes. The dimensions can be adjusted to meet specific length, width, and thickness needs. Shapes can vary from basic geometries like rectangular or round profiles to more intricate designs with unique cross-sections. When it comes to color, FRP pultrusion profiles can be pigmented during manufacturing to achieve the desired shade or can be painted or coated afterward. This allows for matching specific color requirements or ensuring compatibility with existing structures or products. Additionally, surface finishes can be personalized to attain desired properties such as enhanced slip resistance, UV resistance, or fire resistance. Specific performance requirements can be met by applying surface treatments like sanding, coating, or adding special additives. Overall, FRP pultrusion profiles offer a high level of customization, making them suitable for various industries including construction, transportation, infrastructure, and aerospace. They are versatile, lightweight, corrosion-resistant, and possess excellent strength-to-weight ratios.

- Q: What are the features of Glass Fiber Reinforced Plastic Pultruded materials and chairs?

- Glass fiber reinforced plastic extruded sections for chair bars, corrosion resistance, aging resistance, good decorative (wood grain glass fiber reinforced plastic), Candice's color wood grain felt.No recycling value. I'd say that's probably the best feature right now. Installed, no one cares about, will not lose!

- Q: Can FRP pultrusion profiles be used in modular construction?

- Certainly, FRP (Fiber Reinforced Polymer) pultrusion profiles are a viable option for integration into modular construction. These profiles possess advantageous qualities, including a lightweight composition, exceptional strength, resistance to corrosion, and superb thermal and electrical insulating properties. These attributes make them an ideal choice for implementation in modular construction, where the focus is on prefabrication, transportation, and swift assembly. The utilization of FRP pultrusion profiles within modular construction yields numerous benefits. Firstly, their lightweight nature facilitates easy handling and transport, which consequently reduces logistical costs and effort. Secondly, their high strength-to-weight ratio ensures structural integrity without adding unnecessary weight to the modular components. This is especially advantageous in scenarios where weight reduction is critical, such as rooftop installations or areas with limited load-bearing capacity. Moreover, the corrosion resistance of FRP profiles eliminates the necessity for regular maintenance and enhances the longevity of the modular construction. This proves particularly advantageous in challenging environments, like coastal regions or chemical processing facilities, where traditional construction materials like steel may rapidly deteriorate. Furthermore, FRP pultrusion profiles can be easily tailored to fulfill specific design requirements. They can be manufactured in diverse shapes, sizes, and colors, granting flexibility in modular construction design. Additionally, these profiles can be seamlessly integrated with other construction materials, such as concrete or wood, ensuring compatibility with existing modular systems. To summarize, the lightweight nature, high strength, corrosion resistance, and customization capabilities of FRP pultrusion profiles make them highly suitable for modular construction. Their implementation in this field improves efficiency, reduces costs, and enhances the overall performance and durability of modular buildings and structures.

Send your message to us

FRP Pultrusion Profiles - Fiberglass FRP Phenolic Molded and Pultruded Gratings with High Quality/Modern Shape

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords