FRP Pultrusion Profiles - Fiberglass FRP Phenolic Molded & Pultruded Grating

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

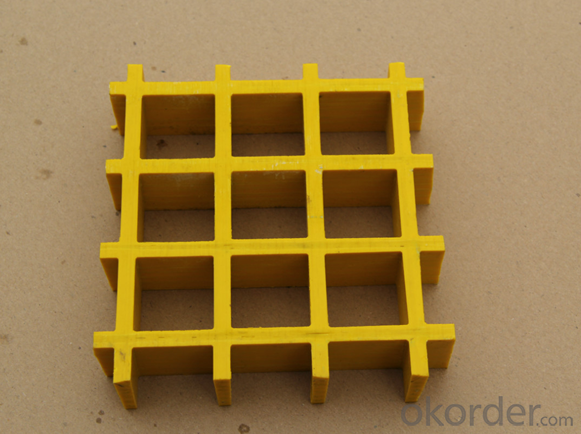

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

- Electrical Insulating

Aging Resistance

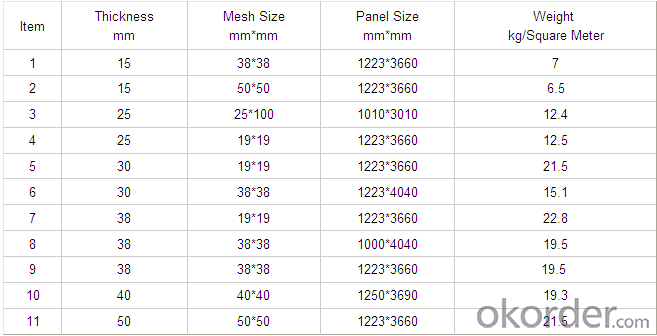

Specification

Advantage

coated with prevent aging layer

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

- Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

3. How is the package?

Usually, we arrange the standard out-package for exporting.

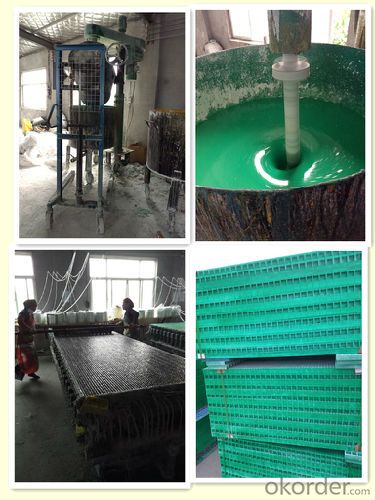

PROCESS

FACTORY

- Q: How do FRP pultrusion profiles perform in extreme humidity conditions?

- FRP pultrusion profiles perform exceptionally well in extreme humidity conditions. The fiberglass-reinforced plastic material used in the profiles is highly resistant to moisture absorption, preventing any degradation or dimensional changes. This makes them ideal for applications in humid environments, as they maintain their strength, durability, and structural integrity over time.

- Q: How do FRP pultrusion profiles perform in high-vibration applications?

- FRP pultrusion profiles perform exceptionally well in high-vibration applications. Due to their inherent structural properties, including high strength-to-weight ratio and excellent fatigue resistance, they can effectively withstand and dampen vibrations without compromising their integrity or performance. Additionally, their non-corrosive nature makes them ideal for long-term use in high-vibration environments, providing enhanced durability and reliability.

- Q: Are FRP pultrusion profiles resistant to impact from heavy machinery?

- The high strength-to-weight ratio and excellent mechanical properties of FRP pultrusion profiles are well-known, making them resistant to various external impacts. However, their resistance to heavy machinery impacts depends on several factors. The impact resistance of FRP pultrusion profiles is determined by their design, composition, and reinforcement materials. Manufacturers use different materials like fiberglass, carbon fiber, or composites, which greatly affect the profiles' ability to withstand heavy machinery impacts. The thickness and overall dimensions of the FRP profiles also contribute to their impact resistance. Thicker profiles offer better resistance to impact loads than thinner ones. Additionally, profiles with reinforced sections or extra layers for structural integrity can further enhance their impact resistance. Considering the specific application and magnitude of impact from heavy machinery is crucial. While FRP pultrusion profiles can generally withstand moderate to high impacts, extreme forces or heavy machinery with substantial weight can still cause damage. In such cases, additional protective measures like impact-resistant coatings or metal inserts may be necessary. In conclusion, FRP pultrusion profiles demonstrate good resistance to impact from heavy machinery due to their inherent strength and durability. However, it is advisable to consult with the manufacturer or a structural engineer to ensure that the profiles meet the specific requirements of the application and machinery involved.

- Q: Are FRP pultrusion profiles resistant to impact and vibration?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally highly resistant to impact and vibration. The combination of resins and fibers used in FRP pultrusion manufacturing makes the profiles inherently strong and durable. The fibers, typically glass or carbon, provide high tensile strength, while the resin matrix offers additional toughness and resistance to impact. Due to their unique composition, FRP pultrusion profiles have excellent energy absorption properties, which allows them to withstand impacts without significant deformation or damage. This makes them suitable for applications where impact resistance is crucial, such as in construction, transportation, and infrastructure projects. Moreover, FRP pultrusion profiles exhibit remarkable resistance to vibration. The composite material's inherent damping characteristics help dissipate and dampen vibrations, reducing the risk of structural fatigue and increasing the longevity of the profiles. This vibration resistance makes FRP pultrusion profiles ideal for use in environments with high vibration levels, including industrial machinery, bridges, and marine structures. However, it is important to note that the specific impact and vibration resistance of FRP pultrusion profiles can vary depending on factors such as the type of resin used, the reinforcement fibers employed, and the design of the profile itself. Therefore, it is advisable to consult with the manufacturer or supplier to ensure that the chosen FRP pultrusion profiles meet the specific impact and vibration resistance requirements of the intended application.

- Q: Can FRP pultrusion profiles be used in the construction of recreational vehicles (RVs)?

- Yes, FRP pultrusion profiles can be used in the construction of recreational vehicles (RVs). These profiles offer several advantages such as high strength-to-weight ratio, resistance to corrosion and rot, and excellent thermal insulation properties. Additionally, FRP pultrusion profiles can be easily molded into complex shapes, making them suitable for various applications within the construction of RVs, including structural components, flooring, walls, and roofs.

- Q: Can FRP pultrusion profiles be used in electrical or telecommunications applications?

- Yes, FRP pultrusion profiles can be used in electrical or telecommunications applications. FRP (Fiber Reinforced Polymer) pultrusion profiles have excellent electrical insulation properties and are resistant to corrosion, making them suitable for use in electrical and telecommunications infrastructure. Additionally, their light weight, high strength, and design flexibility make them a desirable choice for applications such as cable trays, support structures, and enclosures in these industries.

- Q: How do FRP pultrusion profiles perform in high-humidity environments?

- FRP pultrusion profiles have a reputation for their exceptional performance in environments with high levels of humidity. The combination of reinforced fibers and polymer matrix in FRP profiles gives them the ability to withstand the detrimental effects of moisture and humidity. One of the main advantages of FRP materials is their natural resistance to corrosion, which is particularly important in high-humidity environments where moisture levels are significantly higher. Unlike traditional materials like steel or wood, FRP pultrusion profiles don't rust, rot, or decay when exposed to moisture. This makes them ideal for various applications that involve constant exposure to humidity, such as coastal areas or industrial settings. Moreover, the polymer matrix used in FRP profiles acts as a barrier against moisture absorption. This prevents the profiles from expanding, warping, or cracking, even under extreme humidity conditions. The high-strength fibers embedded in the polymer matrix provide additional reinforcement, ensuring the profiles maintain their structural integrity and dimensional stability over time. Furthermore, FRP pultrusion profiles are also resistant to the growth of mold and mildew, which are commonly associated with high-humidity environments. This feature is highly advantageous as it reduces the need for frequent maintenance and cleaning, making FRP profiles a cost-effective and low-maintenance solution. In conclusion, FRP pultrusion profiles demonstrate exceptional performance in environments with high levels of humidity. Their resistance to corrosion, moisture absorption, and mold growth make them a reliable choice for applications that require durability and longevity in such conditions.

- Q: Are FRP pultrusion profiles resistant to hydrochloric acid?

- Yes, FRP pultrusion profiles are generally resistant to hydrochloric acid due to the corrosion-resistant properties of the fiberglass reinforcement and the resin matrix used in their construction. However, the specific resistance may vary depending on the composition and concentration of the acid, and it is recommended to consult the manufacturer's specifications for detailed information regarding chemical resistance.

- Q: Do FRP pultrusion profiles have any limitations or drawbacks?

- Yes, FRP pultrusion profiles do have certain limitations and drawbacks. One limitation is that FRP pultrusion profiles have lower stiffness compared to traditional materials like steel or aluminum. This means that they may not be suitable for applications that require high structural rigidity or heavy loads. Another limitation is that FRP pultrusion profiles are prone to creep, which is the gradual deformation of the material under a constant load over time. This can negatively affect the long-term performance and durability of the profiles, especially in applications where they are subjected to sustained stress. Additionally, FRP pultrusion profiles are generally more expensive to produce compared to traditional materials. The manufacturing process involves pultruding continuous fibers through a resin matrix, which requires specialized equipment and expertise. This can result in higher production costs, making FRP pultrusion profiles less cost-effective for certain applications. Furthermore, FRP pultrusion profiles are generally not suitable for high-temperature applications. The resin matrix used in their production can degrade or soften at elevated temperatures, limiting their use in environments where thermal resistance is critical. Lastly, FRP pultrusion profiles may have limited design flexibility compared to other materials. The pultrusion process typically produces profiles with constant cross-sections and limited geometric complexity. This can restrict their use in applications that require intricate shapes or customized designs. Despite these limitations and drawbacks, FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and electrical insulation properties. It is important to carefully consider the specific requirements of the application before opting for FRP pultrusion profiles.

- Q: Can FRP pultrusion profiles be used in electrical insulation applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in electrical insulation applications. FRP profiles offer excellent electrical insulation properties, making them suitable for a wide range of electrical applications. The high dielectric strength of FRP materials ensures that electrical currents are effectively contained within the desired pathways, preventing leakage and electrical hazards. Additionally, FRP profiles possess low electrical conductivity, reducing the risk of electrical shorts and improving overall safety in electrical insulation applications. The non-magnetic nature of FRP materials is also advantageous, as it eliminates the possibility of electromagnetic interference (EMI) in sensitive electrical systems. Furthermore, FRP pultrusion profiles are lightweight, corrosion-resistant, and have a long service life, making them a cost-effective and durable solution for electrical insulation applications.

Send your message to us

FRP Pultrusion Profiles - Fiberglass FRP Phenolic Molded & Pultruded Grating

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords